Flynn

Members-

Posts

107 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Flynn

-

Any market for old anvils and forge here?

Flynn replied to Dan N's topic in Anvils, Swage Blocks, and Mandrels

Best thing to do to prep for sale/haggling is to clean them up with a wire wheel so all the markings are as clear as they can be, and pay extra close attention to cleaning the face. If there's anything but clean metal there, it will negatively affect the rebound and give your buyer a stronger haggling position. I recommend that you do NOT take a sander or grinder to them in any way. That will upset some folks. Don't worry so much about the maker if you're selling to a smith. Collectors might care, but most smiths will care about the condition of the face, the edges, and the rebound. If you're talking to a young person just trying to get into the hobby, consider giving them a healthy discount to help them out. -

Any market for old anvils and forge here?

Flynn replied to Dan N's topic in Anvils, Swage Blocks, and Mandrels

Isaac Hill was a manufacturer in the mid-1800s. I have a Hill anvil without a pritchel hole, which generally dates it pre-1830 but I've read that Hill made anvils from 1830-1850. Yours is likely in that date range and I assume I have one of the earlier ones. I did not see much, if any, swell underneath the pritchel hole on yours, however, so it could be an early Hill that was drilled later. Either way, it's from the early-mid 1800s and looks to be in excellent condition! -

Any market for old anvils and forge here?

Flynn replied to Dan N's topic in Anvils, Swage Blocks, and Mandrels

Serial Number 16735 should have been made in 1900 according to Postman. -

Pretty close, yes. I prefer mine higher than most folks and it's definitely in the right range. I'm going to weld some tool hangers onto it, but other than that it's good as-is. The anvil didn't budge even when I laid it on its side for transport.

-

Unknown Anvil - Isaac Hill probably?

Flynn replied to Flynn's topic in Anvils, Swage Blocks, and Mandrels

Thanks for the insight! Rebound is pretty good, probably in the 75% range - better than I expected with the crowning on the face. I was concerned about the fire possibility until I tested it. I always try to learn as much as I can about the history of my tools, that's like the icing on the cake for me. -

I suspect this is an Isaac Hill, but could certainly be wrong. It looks very close to another Isaac Hill anvil I have, but there are no markings on it that give much of an indication. The only thing I've found on it are two punch marks on the back that are spaced right between where the numbers for the CWT would be stamped. There are no numbers, just the punch marks (circled in red on the last photo). It's around 160#s with a 5.5" face and has no pritchel hole, putting it before 1830 as I understand things. Am I missing anything that might give more clues to the maker and age? Thanks as always!

-

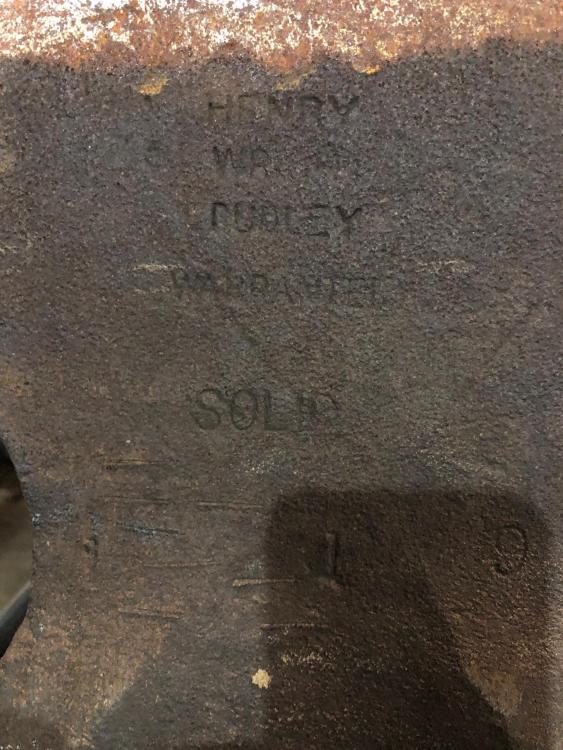

I just picked up this Henry Wright with a nice pretty stand. It's been repaired, but it's got near perfect rebound all across the face and beautiful edges. Whoever repaired it did it right. I hate to say it, but now I'm thinking about selling my Hay Budden now to make room!

-

I am a huge fan of TPAAAT and have had great success with it! I just keep my eye on auctions too, though. I appreciate the advice and information, as always!

-

Nah, it's in an auction that's a few hours away. That's why I'm asking.

-

Don't know, all I have is a few pics. I am assuming its an ASO, but it's hard to tell from the photos. So I come to the experts.

-

Hi, has anyone come across an anvil marked "E.B.M." before? The markings are on the front and back feet. EBM on the back and 1876 on the front. It is obviously cast and looks to be in the 50 pound range.

-

Nope, and they'd have to ship it to me. Just an interesting shape and could be useful. Sorry for posting the link, I didn't realize it was against the rules. I won't do so again. I appreciate the mods being so on top of things!

-

Now I kind of want to make one of these with a different radius on each side. I doubt I'll bid on it because I'd have to have it shipped and that would put it way over what I'd be comfortable paying. Here's the link if anyone else is interested! Commercial auction house link removed per TOS.

-

Hi folks! Just saw this come up for sale in an auction. What do you think, is it just a piece of scrap steel, or is it a specific tool created for a purpose? I suspect it is just scrap, or the arcs would have different radiuses.

-

Anvil with no hardy or pritchel holes?

Flynn replied to Flynn's topic in Anvils, Swage Blocks, and Mandrels

So I went to look at this anvil today and it turned out to be an ASO of cast iron I think. Little to no rebound. It didn't appear to have been welded either. It was definitely cast without the hardy or pritchel. No markings on it of any kind, either. Interesting, but not something I was looking for. -

Anvil with no hardy or pritchel holes?

Flynn replied to Flynn's topic in Anvils, Swage Blocks, and Mandrels

That is my plan exactly, sir! -

Anvil with no hardy or pritchel holes?

Flynn replied to Flynn's topic in Anvils, Swage Blocks, and Mandrels

No, but I'm going to go look at it this weekend, I think. He said he's got lots of old stuff, so I'm goin pickin to see what I can find. So on the off chance that it hasn't just been welded over, I may be interested. -

Anvil with no hardy or pritchel holes?

Flynn replied to Flynn's topic in Anvils, Swage Blocks, and Mandrels

I was wondering if it'd been welded. The rust coming down over the edges sometimes indicates that. My gut is telling me mousehole from the overall shape, but that's all I've got so far. -

Hello brain trust... This just came up for sale near me and I just don't have any idea. I've ever seen an anvil with the modern London pattern with no hardy hole. I've asked the seller for weight and if they can find any markings at all. Anyone have any ideas? Thanks in advance!

-

Thanks for the info!

-

Yep! This would definitely be my outdoor forge.

-

I am fortunate enough to live in the middle of a forest, so I've considered building a charcoal forge and only using fallen wood to supply it. Or trying out different rocket stove designs to see if I can get one up to forging temps. Using fallen wood is about as carbon-neutral as I can think of, aside from a solar/wind/hydro-powered induction forge.

-

Thanks both of you! I had come to the same conclusion myself after looking up other American Star anvils and seeing the greater drop between face and table that they started with. Breaks my heart! I did tell him about the likely milling and he added it to his listing, so he's at least not a horrible person at least.

-

This one up for sale near me. There are a lot of red flags on it through. First being the overall condition, this was either kept locked in a box for 170 years, or has been 'restored'. Second is the paint. Who knows what's under the paint. Third is the price. They're asking $595 and say it weighs around a hundred pounds. I might take a few hundred over there and see if I can talk him down, but wanted what the experts here thought about it. Any advice is appreciated!

-

She said there's a box of bits for the mill, so I'm hopeful there. I will definitely do a close inspection of the entire machine before I decide to buy it or not. Thank you for the concern about older machines not having the safety precautions of newer machines. I'm THAT OTHER guy, though, and I definitely prefer the older machines. I promise I'm always extremely careful, though.