Pat Masterson

Members-

Posts

244 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Pat Masterson

-

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Glowing red eyes - awesome idea -

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Yesterday I finally finished my brothers birthday present. Had to draw out the bar stock under the rams head and get it to the fit around his tow hitch. Then a heart for my mom for Valentine’s Day - kind of embarrassing how long it took me to make that. Funny part was that the only pair of tongs I had that would work with it were the first ones I ever made and were so terrible I swore I’d never use them after I got some good ones. -

Rams head/ Tow Hitch Project Question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

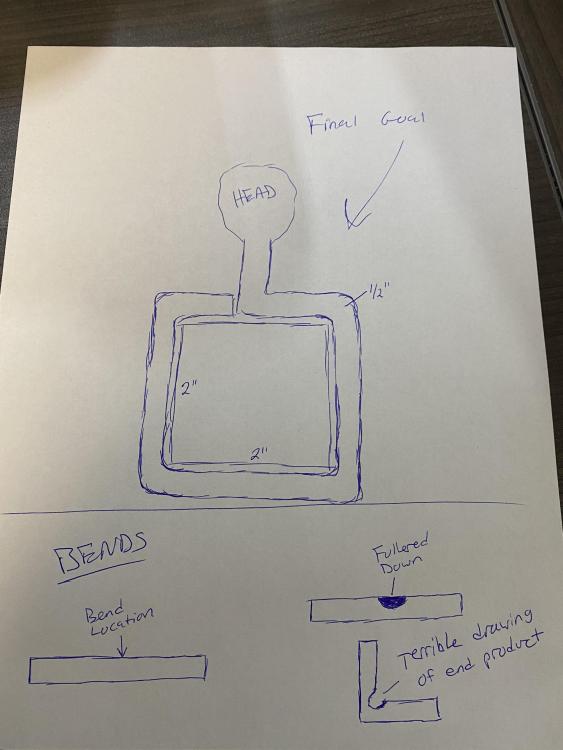

So it turns out I only had about 6 inches under the head so I had much more drawing out to do than I thought but that wasn’t too big of a deal. I went to 10.5” and I’ve got plenty. I went with the “kinks” for the first three bends which worked surprisingly well but I had no room to do that with the last two. I was going to put the kinks for those in ahead of time before I did the third bend and lost the needed space but I didn’t think I’d get them in the right spot that way. I had to stop here - it was just too cold and I was going to start rushing. So now I need to decide if I cut off enough to make the end meet the outside corner of the first bend or if I want to angle that last straight piece behind the head a little and go all the way across the top and over the right top corner for a second time. Considering that just because that final bend would give me a chance to tighten it up even more. -

Rams head/ Tow Hitch Project Question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

All very helpful. We’ll see how it goes in the morning. Thanks guys. -

Rams head/ Tow Hitch Project Question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

Ok so maybe I draw it out to 10 or 10.5 and cut of what I don’t need. Then I have some room to play with. Thanks. Any suggestion on that way of bending I so eloquently described and drew? The reason that gets in my head is because I don’t have a vise...yes I know but I’m saving for a good one...but I’m just looking for any tips on how to get nicer sharper bends at the anvil. -

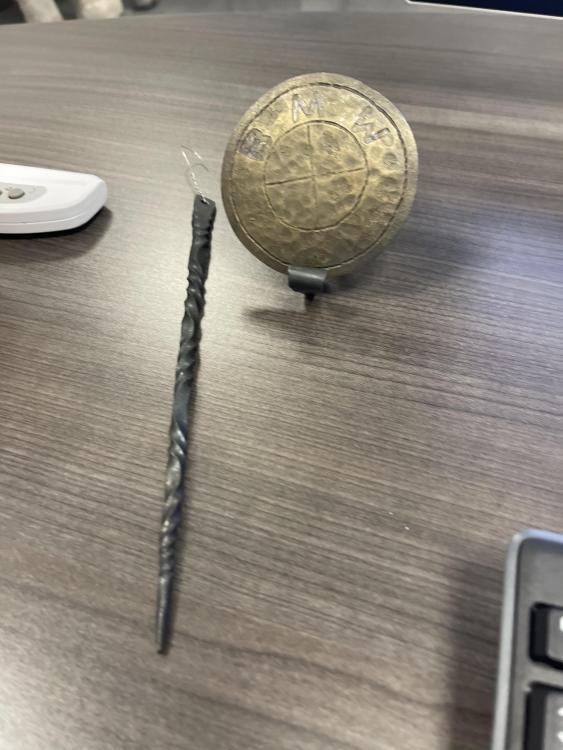

Good morning all - so my brothers initials are RAM, he drives a Dodge Ram, every username he has uses RAM in some way so naturally for Christmas I made him a rams head. I left it unfinished though so he could decide what he wanted it to actually be. We came up with bending the untouched bar stock the head is on to wrap around his tow hitch so that the Ram kind of stares at the car behind him. I don’t know how to calculate how much length of the 1/2” square stock the Ram is on that I would need to wrap up around the 2”x2” hitch though. Simple math would say I need 8 inches but won’t the bends affect this? Right now I have about 8 inches after the bend directly under the head so I can just draw it out if I need more. And then the bends/corners themselves - I’ve seen people put what I would call a “kink” in the corner before bending (usually i see it in dinner triangles) but basically use some kind of fuller to thin out the place of the bend. I guess it’s to make a tighter bend? Adding some pictures so you guys can get a better idea of what I’m going for but I’d really like to know how others would approach this as I’m still basically brand new in this. Thanks.

-

Try it both ways! Why didn’t I think of that lol. I do have enough. Thanks.

-

After some more research it looks like you’re right - there’s no reason 1/8” is too thin. I actually saw some that had a 3mm width. So do you think my best bet is just cutting out a rough shape then grinding/sanding in my final shapes and blade edge? No forging? I was looking forward to trying to forge this stuff but I want to go with whatever has the best chance of creating a nice usable piece.

-

Awesome, thanks.

-

Follow up question. After I forge and sand and do what I need to do, do you think I’ll have to re-etch it? I don’t have any ferric chloride or anything so I’d want to get it ahead of time if I’m going to need it...

-

Very helpful. Thanks guys.

-

Good morning all. So I wanted to have a go at forging a Kiridashi knife and it just so happens that I was given a piece of damascus as a gift so I’d like to make it from that. I don’t know the quality of the Damascus- I believe it’s one of those you see on Amazon or something advertised for knife making. I considered laying the shape out, cutting it out and then just doing some minor forging for final shape and the blade but my problem is the thickness of piece - it’s 1/8” (2”x10” HxL)The Kiridashi’s I see online look thin but not that thin so I would need to try to upset a good portion of the damascus, at least enough so the handle section is thicker than 1/8”. I have a gas forge though so usually I’m using selective cooling if I want to upset a certain section of stock- but I’m assuming since this stuff is advertised for knife making it’s some kind of high carbon steel so if I quench it off will it be too brittle to start beating on the quenched part? If that’s the case and I shouldn’t quench will I be able to upset forging it horizontally? Or do you think that will just make the piece longer? First time trying to make any kind of blade and first time working with anything other than mild steel. Thanks.

-

I guess it’ll take a little maintenance here and there to keep it looking right. No big deal. I haven’t tried forging with stainless yet but I really want to. I hear it’s tough stuff to work with.

-

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Precut Angel Blanks

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

Update : So I ended up just using and angle grinder with a cut off wheel for the big cuts, hack saw for the tight stuff and then I cleaned it up on the bench grinder. Worked well and this is by far my favorite piece so far. -

Project question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

So I ended up going with just brass plating for the finish. The project did not come out how I wanted, especially the letters themselves. I wish I had thought to make the tool for stamping in the letters before I had tried the other ridiculous ideas. I’ve heard rebar isn’t good for tool making but I guess I got lucky and had some higher grade stuff because they definitely hardened. First time making any kind of tool myself (chasing chisel and I guess it would be called a small square punch? - although it’s intent and use was not to punch holes) and hardening and tempering so that was a lot of fun. Could’ve been much better and I wish I had got better pictures before giving it to the person it was for but I learned a lot. Thanks for the advice and ideas though. -

Thanks everyone. Much appreciated.

-

Ok - any suggestions for something more permanent? Clear coat to spray on over the paste wax or something?

-

Hey guys - is paste wax going to be enough to stop rust for something that will permanently be outside? Like a dinner triangle for example. Thanks.

-

Hey guys. I did my first projects with brass brushing this weekend. I really like the way one of them came out. Gold wings and halo on an Angel. But the other one which I of course forgot to take a picture of I’m not happy with. I made a BMW hood symbol as a Christmas gift. I didn’t want the coloring to be as heavy as it is in the Angel. I just wanted it to bring out the texture a little. How can I go about lightening it up a bit? It already has a paste wax finish on it as well. Thanks.

-

No flux but it has been up to forge welding heat quite a few times

-

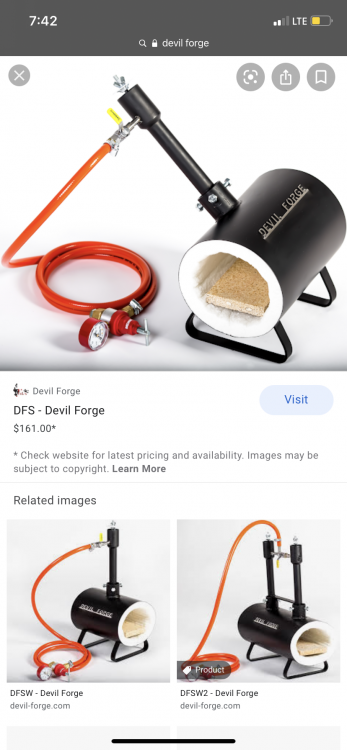

Good morning - I was curious if anyone had a brand of fire brick to recommend for the bottom of my propane forge. I’ve had it about 8 months and it held up pretty well but then it in about the last month it’s become pretty bad. I can’t tell if it’s the brick itself that melted or if it’s from the work itself but it basically looks like a puddle of steel that hardens when the forge cools. When it’s hot I can feel the work sticking to it and some of it will actually come off and stick to the work. I will add pictures. But like I said it lasted pretty long then this seemed to come out of nowhere so I flipped the brick but now just after two sessions on the fresh side I can see the same thing starting to form. It’s the brick that came with this devil forge I bought. So is a better fire brick needed or is this going to happen regardless? Thanks.

-

Thanks for all the help here guys. Going to try to find that neutral flame tomorrow. Working on a project with steel plate rather than bar stock which is actually where I’ve had the most problems with this issue. I’m sure I’ll be back with more questions.

-

Ok..so the more open the choke is the more oxidizing the flame?

-

What did you do in the shop today?

Pat Masterson replied to Mark Ling's topic in Blacksmithing, General Discussion

Beautiful work. I want to try the brass brush. Do you put any kind of finish on after the brass like paste wax or linseed or oil or just leave it? I’m assuming any of that stuff on top of the brass would dull the color and make it look more black.