Pat Masterson

Members-

Posts

244 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Pat Masterson

-

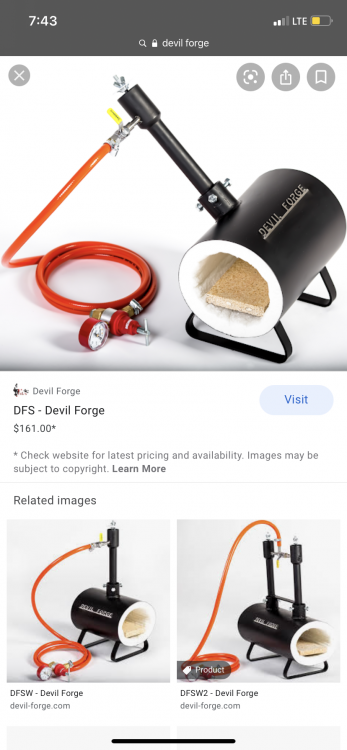

I meant to mention the forge set up, sorry..it’s from Devil Forge - the smallest one they make with one burner. The forge confuses me to be honest..i thought the higher the gas pressure the hotter the flame but that doesn’t seem to be the case. It seems to get its hottest running between .1 and .2 mpa with the choke open a little more than half an inch...could the choke being too far open affect the scale or should I be able to take care of it by brushing at the right heat regardless? Like I said there’s a definite sweet spot for the choke/gas pressure setting regarding the way the burner runs..it will sputter a bit if it doesn’t like the way it’s set up. Should I try to find a setting that doesn’t cause the sputtering but has the choke closed more? In the end I’m able to get a nice finish after filing, bringing it to a really low heat and then applying the paste wax but I just feel like I should be getting there much easier.

-

Hey guys- so I’ve posted about this one before but I’m revisiting with more detail because I must be doing something wrong. Everything I’m making but especially the smaller stock stuff (3/16,1/4,3/8) has this terrible coating of very thin scale. I have a good butcher block and I’m going after the scale as hard as I can but it’s still there when it cools. Maybe the finish in the pictures looks ok but if I were to drop one of these pieces on the driveway for example, a little piece here and there would chip off. And you can see they are not smooth at all. So before I put a paste wax finish on I’m having to file/sand almost the entire piece to bare metal, then bring it to a black heat and at that point apply the paste wax. Seems like anytime I watch a video they forge, wire brush a bit but not excessively and then just do some minor file work depending on the piece before doing the finish. Am I doing something wrong? The picture with a bunch is right after they cooled. The second with just two pieces shows what I’m having to do to them before putting the finish on. I really appreciate any help.

-

Hey guys.. I have a follow up here - so I got a better brush, a butcher block from blacksmith depot, and it’s a huge difference. But I’m planning to make a couple things from a piece of 1/8” A36 plate I bought. I threw some cut off pieces in the forge the other day to test a touch mark I made and the scale on the plate was just crazy...like I had never seen before (in my very long 6 months of blacksmithing lol) but still it surprised me. It seemed like it was scale on top of scale straight from the forge without even getting to the anvil. This was my first time with anything other than round or square bar so does plate just act differently? I was under the impression the bar stock I was using was A36 also so that’s why I bought the specific plate I bought. Can the way I have this small propane forge set up be causing more scale than it should?

-

Hey guys - so I have a devils forge - small single burner propane forge from eBay. Has been working well for a few months now but the refractory stuff it came with got chipped off in a few places today. Large enough spots that I definitely want to fix it before I use it again. Anything you know of that I can use from Home Depot, lowes or somewhere similar? I need to get it going ASAP so I rather not wait for something to be shipped to me. Thanks.

-

Pnut- you were right. The burner did not burn the same outside of the forge. Would barely light if the choke was open even a little and with it almost completely closed it was just more of an open flame. Had to just go at it at the anvil. Definitely could have been better but for my fourth project ever I’m pretty happy with it. Those are not the screws I’m going to use by the way lol. Just test assembly. what kind of screws would you guys use? I know I can strip the zinc ones with vinegar then heat and wax to match the rest which I might do but curios to see what you guys say...The holes aren’t countersunk I meant to add the video not the picture IMG_3503.MOV

-

Project question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

Oh man...the enamels might look really good..I almost wish I hadn’t seen that haha. -

Yeah I do use the selective cooling from quenching some times but I have a VERY budget friendly vise so I’m always struggling to quench where needed and then get it set up correctly in the vise before it’s cooled too much. In the long run I just need a better vise but for now I’d like to have it set up perfectly and then apply the heat where I need it.

-

So I want to do some bending in 1/2” round stock but I want to really localize the heat for tight bends. With the holidays coming the budget is super tight...I know the small HD propane torch won’t get 1/2 hot enough so instead of buying a bigger better torch kit could I not use the parts from my propane forge? If I take the burner out of the forge it’s kind of like a torch with no handle but I can manage to find something to hold it with..I’m brand new to forging so I’m not going to be surprised if someone says this is a completely stupid dangerous idea for some reason lol...let me know. My forge is basically the same as the 1 burner forge in the top of the pic. Thanks.

-

Project question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

Thanks guys. Super helpful especially not cutting it to the finish size with the first cut. I’ll let you know how it goes! -

Project question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

Hey John. By “two circles” I meant - if you look at the picture I attached there’s the outer most edge, then a circle that’s maybe 1/16” into the piece that kind of forms a border around the whole piece. Then there’s the bmw lettering and then the inner circle that contains the blue and white sections. I guess I could just do the inner circle but I’d like to try to get both. Everyone’s comments are really helpful though so thank you! I just got the plate yesterday and laid out the circle for it. I’m also doing an Angel ornament. The way I see it I have three options to cut them out with the tools I already own: 1. Cold chisel (but my cold chisels are from Amazon and not very good) 2: hacksaw or 3: dremel with cut off discs. So I guess I have the same question again...how would you do it? -

Project question

Pat Masterson replied to Pat Masterson's topic in Blacksmithing, General Discussion

That’s definitely the type of edge I’m looking for..but the outer circle needs to be 3” diameter or just shy of that...do they make sockets that large lol? Im imagining I’d have to buy a set if they do which may be a bit expensive for this one use -

Good morning everyone. So I want to make a BMW symbol from 1/8” plate for a Christmas gift. It’s going to be 3” in diameter but I need to make two clean circles to give it the same look as the picture I hopefully attached here correctly. One circle all the way on the border and then a smaller one in the middle. I’m struggling to figure out what to use though...maybe I leave just a bit extra on the diameter and use like a 3” and 2” pipe or fitting that I could use kind of like a stamp? Haven’t been able to find something like that with a nice clean edge though. Or do you think I can do it with a very small chisel or will that just look like a bunch of straight chisel marks in a circle? Let me know how you think you’d might do it. Thanks!

-

It’s a propane forge. That’s an awesome post though. I do plan to move to coal eventually so thanks!

-

Good morning all - I saw a YouTube video of a smith making an angel ornament from a precut blank but the link he attached for the blank is no longer active. Anyone know of someone selling something like that? I haven’t had any luck through regular google searches. Thanks!

-

Wow..I wasn’t expecting responses so quickly. This site is awesome. Now I’ve got a few things to try to fix this finish. Thanks guys! Frosty- thanks for the safety tips! Much appreciated.

-

Hi everyone. Brand new here so I hope I’m posting in the right place. 2 pieces into blacksmithing- an icicle tree ornament and dice bottle opener. I’m having the same issue with both though. The bottle opener especially has a lot of scale. I brushed it as hard as I could when it was hot (may need a better brush as I just have a Home Depot brush) but I put a paste wax finish on it and now a lot scale is chipping off very easily. Can I put it back in the forge to a very low heat and brush some more? Can I file it and then into the forge to a very low heat? Will that bring the dark finish back after filing? Do I need to remove the paste wax with turpentine or something before heating? Any help is much appreciated!! Thanks.