Bonnskij

Members-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Bonnskij

-

Weighs about 150 kg. It's a John Heine 182a, so that makes it a 3 ton press I think. I don't know the weight of the counterweight.

-

Look what followed me home! Haven't gotten to try it out yet as passing cyclone and subsequent flooding took precedence, but hopefully within a couple of days!

-

Thanks. I've bought and set it up in the backyard now. Loading ut with a fair bit of mass should be possible.

-

Hi all. I have an opportunity to buy a flypress (john heine 182a). It's a three ton flypress if I'm not mistaken. Comes on a stand and total weight if stand and press is about 300 kg. I'm not however able to bolt the press/ stand to the floor where I live. Is that necessary with the amount of torque a flypress produces?

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

That sounds really fantastic Frosty. Would love to see some pictures! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks everyone. Im really flattered Really happy with how the chef turned out in the end. Been procrastinating on that one for far too long. Glad i used an oversized pice for the handle as i managed to break both one and two drill bits and had to grind the wood down to get them out. I love the variation in this wood too Frosty. Incredible amount of variation. I've seen some really beautiful quilt figure pices before as well. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

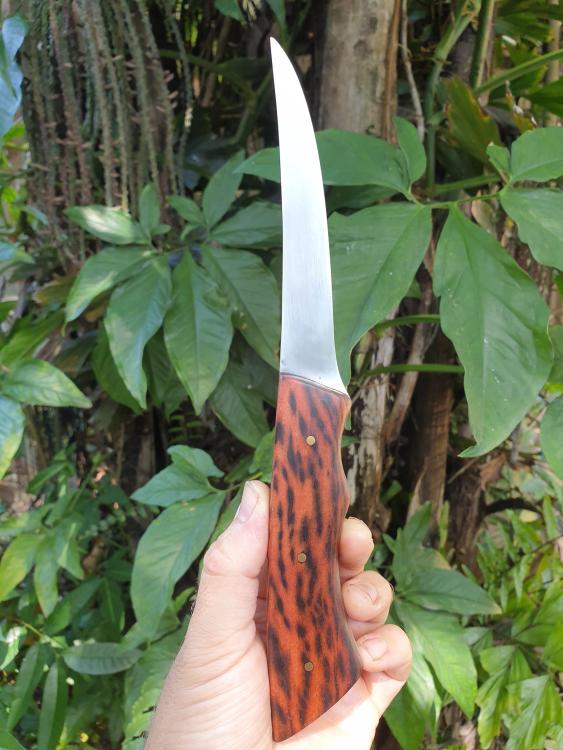

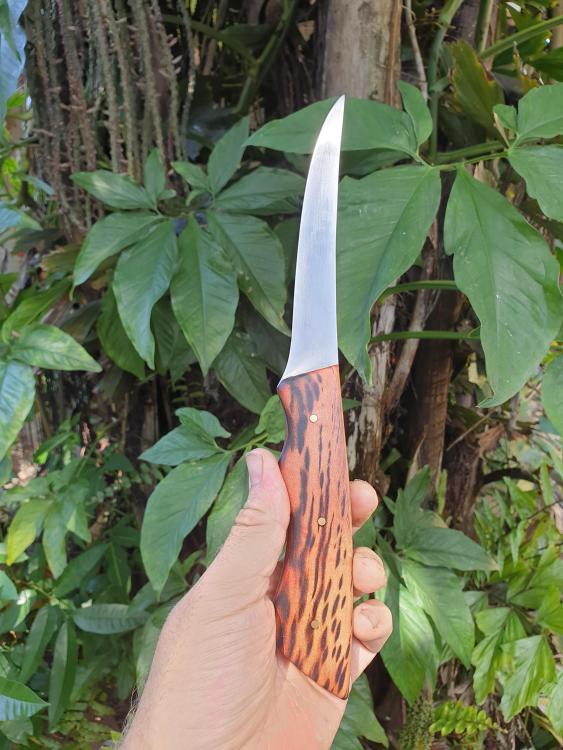

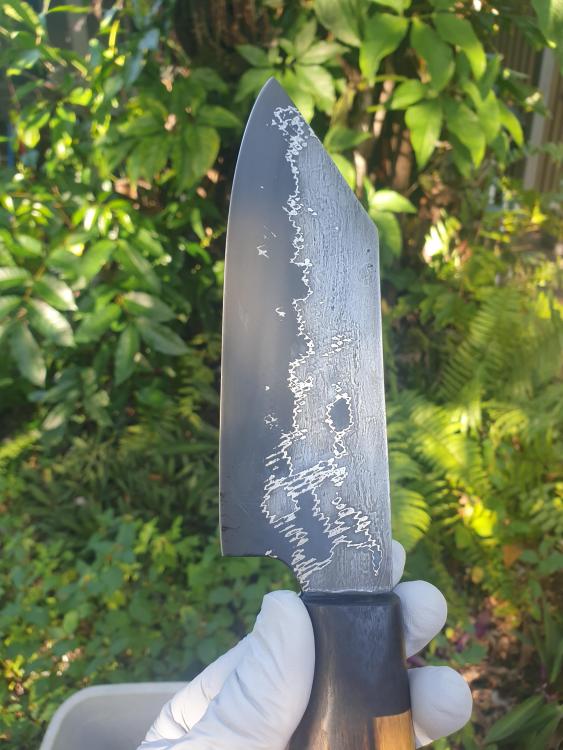

Long time no see! Made a big hook and eye latch for a lady's fence gate. Though strictly speaking stock removal npt forging, here's a filet knife I made. 15n20 blade and Tiger myrtle handle. Finally finished this chef knife as well. High carbon core from an Australian made Wiltshire file. Wrought iron from 200 year old anchor chain and a nickel shim. Handle is pale moon ebony with a 5000 year old ancient redgum bolster. Currently in the process of applying finish: The local museum is also selling some of my things now, which im really quite proud of! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thank you! Really appreciate it! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

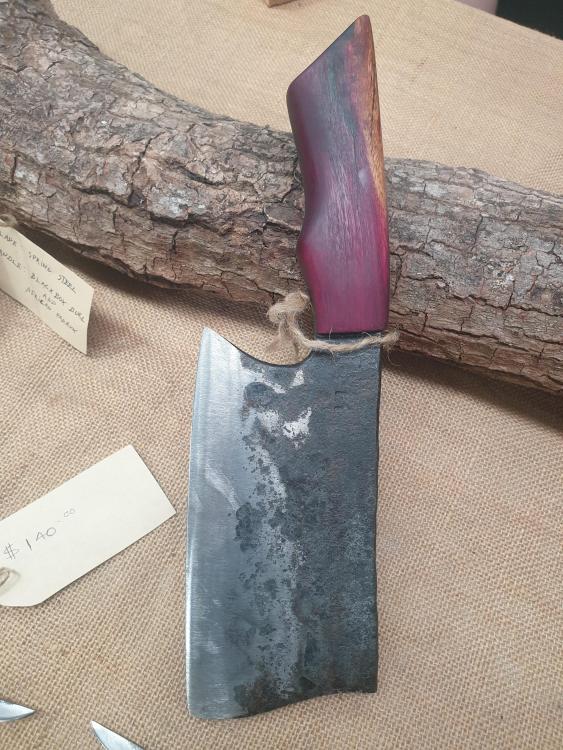

New cleaver with a couple of firsts. This is my first bottle style handle and pin for a hidden tang handle. Leaf spring cleaver with black box burl and maple handle with a brass pin. A few railway spike tap handles I just completed for a local brewery opening soon: My partners old clothes airer was getting pretty rusty, so I bought a new one and turned the old one into heart pendants: Another bottle handled cleaver. I feel like I keep changing the design of these cleavers, but I think I'm getting close to the final iteration now. Figured buloke and maple handle: -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

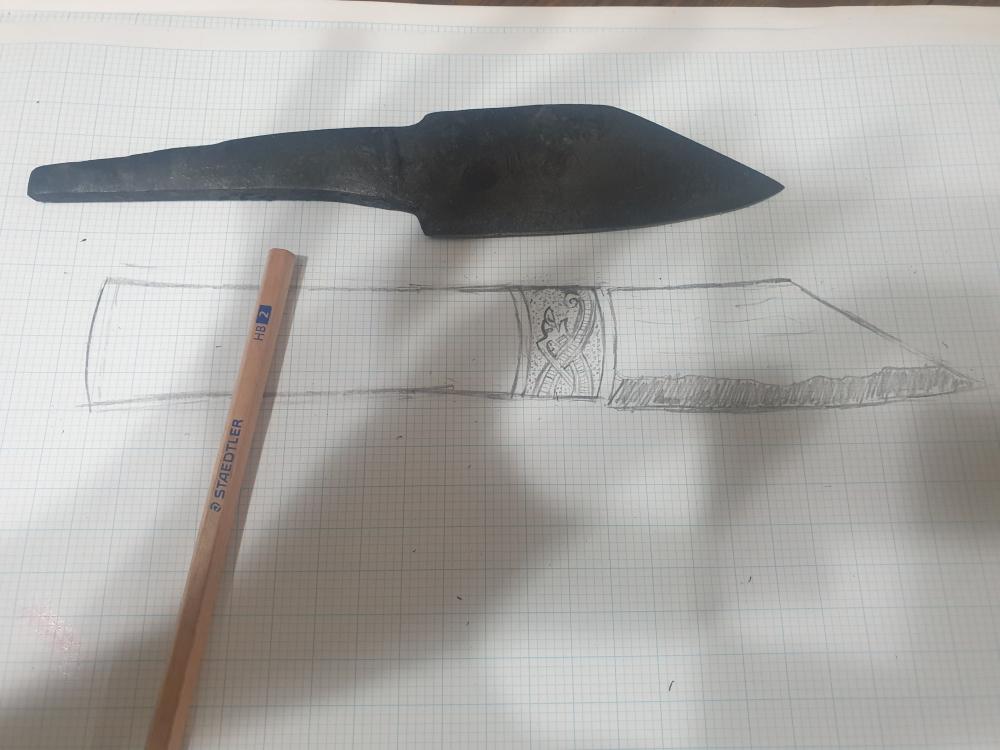

I've been a bit short on knives on the last few markets, so brought a couple of works in progress with me to fill in space and see if there's some interest. Here's a chef knife in the making with a file steel core, 200 year old wrought iron anchor chain jacket and nickel shim that will be getting a pale moon ebony handle. Also a seax I based of a picture from a phd thesis which slips my mind right now. Anglo-norse ironwork or something along those lines. W2 core and wrought iron jacket from a wagon wheel I picked up from the tablelands. Course and gorgeous old iron. Ringed gidgee handle with a bit of carving work on if I'm up to it. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Here's a big whopper of a chopper that sold before I was halfway finished. The bloke who bought it gave me a big hug when I finally finished it and was absolutely beaming when I met him about a month later. Experiences like that makes me so happy to be doing this Spring steel blade, buloke handle and carbon fibre pins. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks Thomas! The family managed to sell that one on Sunday -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks folks! I think my other half is generally better at sales than me (though I can rattle of spiels on metallurgy and blade history a bit more to anyone who wants to listen, or is too polite to run away). And the kids are ofcourse adorable (not that I'm biased at all ) -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Been a while now. (Appreciate the scientific explanation for tent pegs bytheway). The maker space had to close down for a month and a half, so things got a bit difficult for a while. Couple of pictures from the last market where for the first time, nothing sold. Oh well. Had to happen eventually: Now I'm sitting at home with Covid while my other half and the kids are taking care of the last market of the year. I've heard they've done pretty well so far. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks George. I actually planned to do a twist in the tent pegs, but currently have my vise set up in a separate location to my anvil. I don't know what the optimum angle for tent pegs is, but that's a good point. I hope to test them towards the end of the year. Haven't had a proper holiday in years... really looking forward to it! Didn't think of breaking the edges Thomas. I should have. Better do that now I think. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I would certainly be nervous about letting someone i don't know near my tools. I have had a lot of people ask if I do lessons or if I can teach them, and first of I don't think I've been in the game for nearly long enough nor know enough to be teaching anybody, and second I don't want that kind of responsibility for somebody's safety or letting people use my tools. I also enjoy just doing this by myself to be honest. Beautiful thing JHCC. What is it exactly? Also, someone wanted a set of custom door pulls: I'm getting a slowly but steadily increasing amount of custom request at the moment. Compared to just making what I like, I'm not sure what I think. I feel the pressure of getting it right to what the client likes as opposed to just something I like is relatively stressful. Im obviously just doing this as a little side gig, but still feel that in the current economic climate I can't turn down a lot of work either. I do like these pulls though, and I had to learn a couple of new things which will be useful down the road. Also made some cyclone resistant tent pegs. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks Frosty. There's so many beautiful Australian handle woods. Looking forward to using a few other ones that I have stashed aside currently. Yep, it seems very much a work in progress at the moment. Looks like they've got funding to get some impressive gear, and then they're trying to recycle and reuse a lot of other stuff which I think is great. I hope they manage to keep developing and it seems they want to be able to be open more often. The garage space sounds like a great idea too. Wish there were more places in general where people with no space could still be able to engage in their passions or work on projects. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Made a cleaver with a buloke and ancient redgum handle and this custom carving knife with an octagonal western myall handle. First spear point knife I've made. Maker space is working out pretty well. My anvil is left alone. People like watching me make stuff and most days it's just me there. Though its only open for at most three evenings a week which isn't ideal. Got access to a big bandsaw though, so can cut up some of my larger and more exotic wood blocks. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Yeah it's a bit exhausting that's for sure. Don't have a luggage rack for the car. I'm able to fit everything bar the anvil though. And my anvil is left alone. It's open three evenings a week. There's not a lot of people, and I can be there most of the time. Broke the eye of my most recent axe... wrought iron. Fixable or just best off scrapping it? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Well the anvil is mounted to a stand which probably makes it around 70kg. My car is also tiny, and i need to maintain my ability to pick the kids up from school and daycare, with a very limited amount of hours in the day that I'm trying to make the most of. It's not ideal. But it is what it is. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Yes, those are all certainly some concerns of mine. I will have a tool box with the tools i intend to use for the most part. At the end of the day, I do things fairly bare bones, so that shouldn't be too much trouble. The anvil I will have to leave in place. I have quite recently acquired it. Just a cheap 30kg, but steel and a massive upgrade from what I was previously using. I am open to leaving my forge if people are interested, though I would like to have it available at home for twisting and heat treating, (unless the neighbours even have a problem with the slight roar of the forge too...) In which case, people would certainly need to bring their own gas. Mandatory training is a must for sure. I want no welding or cutting on the anvil. I also have a small belt grinder in my shed. I was hoping to keep using it as it would be a lot more quiet than the anvil and angle grinder i use outside, but my partner doesn't think it's a good idea. Renters have deplorably few rights in Australia, so I should probably listen the voice of reason... I don't really have a problem with anyone using my grinder. It's not hard, and it's not super expensive. Provided mandatory training and people supplying their own belts ofcourse. I'm happy enough to donate my old belts which will still work fine for steel and with no problem for wood. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks fellas. Some space is better than nothing. Frosty, I should be able to keep some stuff there. Primarily my anvil. I'd like to take my forge whenever I need so that I can still do heat treating and twisting at home, but we'll see. I think I can keep whatever I like there pretty much. On the plus side, I'll have access to much more tools, including cnc router, laser cutter, electric kiln and a larger bandsaw than I currently have. Could be a positive overall. Still working on my photography. The axe does actually have a proper poll. It just doesn't show because as you said, it's too dark.