Bonnskij

Members-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Bonnskij

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Latest completed axe. Mild steel body and spring steel edge. Over three years into this venture and some neighbour has finally taken umbrage with me working out of my backyard. I'm staying within legal hours and doing what I can to mitigate noise, so it wouldn't be much of an issue (for me at least) if I owned the place, but alas, the voes of being a renter. Found a maker space between here and my job that seems positive to letting me set up with them though, so hopefully it all works out. Frustrating time for it though, as this smithing venture seems to have steadily picked up, and I've somehow gotten several custom orders lately. The markets have been going great and I'm being visited by people who bough knives from me and are stoked about how well they hold their edge. It really feels great, and this whole thing has been really good for my mental health. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Well. I mostly associate fire pokers with fireplaces. I suppose the concept of car camping and thus packing everything but the kitchen sink is always going to be foreign to me. Pack light and partially live off the land is the camping I grew up with. A fire poker never made it as part of the kit Nothing but bugs in tropical Queensland. Big enough that I could probably sell spears to fend them off with. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

For some reason I've gotten several requests for fire pokers on the markets. Not really something I'd expect in the tropics, but now I've made a couple at least. Good fun! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

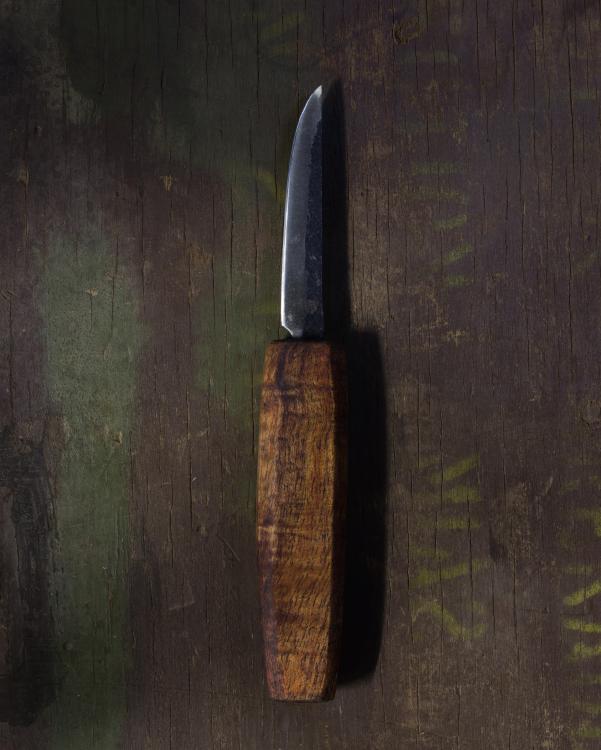

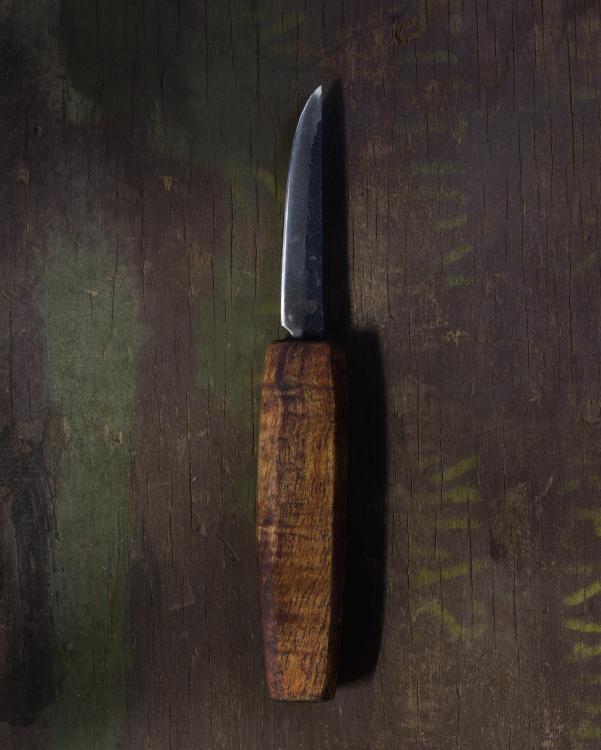

I try to time myself on the things I make and price myself accordingly. I watched John Switzer's video on pricing your work and have found that quite helpful. I try to take fair market value into account as well, so for something like hooks I can get maybe $90 an hour for my time while a cleaver is perhaps $30. I certainly won't try to price myself at a level that undermines the craft or the amount of work that is put into it. I am also continuously debating whether to take my rudimentary tool setup into account. I know I'm competing with people with power hammers, forge presses and large belt grinders, so do I price my work as if I'd saved time by using these tools, or by actual hours spent? Anyways. One finished kitchen knife: -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

That's a good point about pricing. I hope I'll be able to find the right balance eventually. I'll be putting up the price on some of my bottle openers next market, so should be interesting to see how that goes. -

Ingenious Cambodian blacksmith

Bonnskij replied to arkie's topic in Axes, Hatchets, Hawks, Choppers, etc

At first I thought: "What do you mean? He's got safety goggles." And then he picked up the circular saw... I love these videos though. Very impressive. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Yes, I've sort of been trying to figure out what sells by making all sorts of things and after doing a few markets, I'm not all that much wiser... I have learned a couple of things though. People are more willing than i expected to buy more expensive items, and that's where I've made most of my income from sales. I sell enough hooks and key chains and such to cover the cost of doing a market basically. Also, squirrel cookers are apparently not that popular around these parts... And out on the country side the sales are more skewed towards the expensive items than closer to the city. I also got a new job with a fish exporter doing water quality management and other things as needed. Not as much hours as I'd like lately due to Chinese ports being closed but hopefully that turns around soon. Good to get a bit more income though, especially after being shafted by the university for my severance pay (they must have a whole department dedicated to making loopholes). All I got for nearly seven years of work was a kick in the backside. I shant whinge too much though. I didn quite realise how much of a toll that place had taken on my mental health. Anyways. Work in progress. New market on Sunday. Wonder if anyone wants it: Figured Tassie blackwood, copper and 5000 year old ancient redgum. Also picked up a bunch of wrought iron My strategy is definitely to make things I enjoy making. I'm always having fun when I get to fire up the forge! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

From a market the other weekend. Still have most of the sløyds left, but the cleavers I had practically flew off the table. I don't know how I somehow fell into cleaver production, and that somehow being the most popular thing I make... -

What's your latest blade look like? Post em and let us see.

Bonnskij replied to HondoWalker's topic in Knife Making

Here are my last two. One cleaver with zebrawood and padauk handle(the padauk is in the middle, so not visible on that photo) and one sløyd with Tasmanian blackwood handle. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Another heat treat test. This time in the dark. Worked out a bit better. I'll keep heat treating at night time. Previous test at the bottom. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Tried experimenting a bit with heat treating some 1084. Suppose this isn't exactly the best result I could've hoped for. I'll try again in the dark. That's when I always do heat treating anyway. -

What's your latest blade look like? Post em and let us see.

Bonnskij replied to HondoWalker's topic in Knife Making

I seem to be mixing up a couple of species, or the palaeontology has been revised since last I saw. There used to be a small dog sized carnivorous kangaroo as it turns out and a giant 2.5 meter tall one; which does look like the stuff of nightmares but seems to have been herbivorous. Conveniently there is an extinct Australian crocodile species named "the cleaver headed crocodile". -

What's your latest blade look like? Post em and let us see.

Bonnskij replied to HondoWalker's topic in Knife Making

Well I've dubbed it the mastodon cleaver. Perhaps Giant carnivorous kangaroo cleaver fits better for the land down under though. -

What's your latest blade look like? Post em and let us see.

Bonnskij replied to HondoWalker's topic in Knife Making

Definitely falls between the two as far as potential usage goes. I was sortof going for a fantasy inspired hog splitter. That being said, I have no hogs to split, so it has been clearing up the brush in the backyard. Small palm trees and tightly growing brush seems ideal. The wide blade makes quick work of several small to medium sized plants at a time. I used a big truck leaf spring. Have given it a good run for its money and I'm really happy with how the edge holds up. -

What's your latest blade look like? Post em and let us see.

Bonnskij replied to HondoWalker's topic in Knife Making

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Seems to be the case i suppose. I did point out there was no difference between the blades though. And I reckon my blades come out pretty alright these days. No chipping or rolling when testing on bone and brass in any case, and the grain is really fine. At least you'd hope someone who spent a lot of time on their handle wouldn't want to waste it on a sub-par blade. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks everyone! I'm really stoked about how it turned out. Invest in quality materials / gorgeous handle woods, as people are willing to pay for it and it will be worth it in the end? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I don't have a proper photo of the blade for this one, but wanted to show off the handle anyway. I'm experimenting a bit to figure out what there is a demand for in the market around here and used some rather expensive ringed gidgee and ancient kauri. Priced it substantially higher than some other cleavers I had for sale and it was also the first cleaver to sell the next morning. I also got a job as a seafood processor. I worked for one day and was told the season was over and would restart again in July. I had to laugh at that one -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Found round bar eventually, so now i have heaps of hooks. Working on another axe too. Here it is so far: -

Damascus Copper or Brass added to knife blade?

Bonnskij replied to Francis Trez Cole's topic in Knife Making

I think he's referring to what commonly goes by cu mai these days. Laminated blade steel where there is a layer of copper between the steel layers. -

Cheers. I'll certainly give it a go.

-

Hi everyone I've been working on a leuku in 1084 that when quenched came out with a bit of a twist. So far I haven't had a problem correcting banana warps by repeated tempering cycles with a clamp, but I'm wondering if there's a way to untwist a blade in similar fashion.

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

It sure is a bit of a first world problem I do a bit of upcycling, but hard to find scraps at the right size for the hooks. Having the round bar it was easy to churn out a lot of them after making a jig. I got a few half finished big knives, so i'll see if I can finish those before the next market. I have two weeks as it stands. This has certainly been a learning experience for me, and a lot of fun. And most importantly I've managed to connect with another couple of blacksmiths in the area.