Bearded Welder

Members-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Bearded Welder

-

Well I would like to take a moment to thank everyone for there advice and especially you Frosty, with your help with this press as well as burner and forge advice...but unfortunately my wife just quit her job (came with living on a farm with a shop) so we are moving back to the city and I will have to put my blacksmithing on hold and in storage for now until i have a space to work in. Again thank you very much! Cheers Phil

-

So I picked it up, guy knocked off more money because ill have to customize it, he didnt have to but really nice of him. Banana is for scale. I took pictures in the kitchen before my wife came in so it would be bright instead of the dreary shop. I knew it would be small, in terms of the opening but I didnt think the cylinder would be as short as it is, he said its roughly an inch long, maybe a little more, ( he also thought the cylinder was 3 inches in diameter) so I think that means I will need multiple dies (that do the same thing) of varying thicknesses to accommodate the work, if i have something that is 3 inches thick, my dies cant be bigger than a half inch each, but if I have work thats only a half inch thick I will need larger dies to reach the work before maxing out the cylinders reach.....does anyone forsee i problem with my line of thinking on that regard? I am going to design a type of spring return mechanism that also holds the dies. Another problem I forsee is in the 3rd picture, the top die slids in, I wouldnt be able to have a drawing or flat die on it because id never be able to pull it out of its housing to switch, unless thats what the 2 screw holes are for? I havnt really looked at it closely, I just got home and snapped some pictures, hopefully this weekend I will be able to examine it some more. Any thoughts, questions, concerns, witty tunes or bad jokes lay them on me! Cheers Phil

-

No worries Brianc! All thoughts and comments welcome. Ive looked up the pump that goes with this unit and it is a full hydraulic power pack normally, so thats what ill be looking at. My only concern is the forging end of things..I didnt realise how small the opening is, its basically a 4 inch by 4 inch square, then take into account 3/4 inch dies, the opening would be 2½" tall but i guess for knife making that should be big enough? Thoughts anyone? Ive also been trying to find the cylinder size online so that i can figure out how much GPM i need to run it at a decent speed but so far no luck.. Cheers Phil

-

Going to pick it up later in the week! Thanks for all the help! And yeah ill probably just stick with the lever to be honest. Though I suddenly have an image in my head of a cave man pounding on steel with a lever Ill try an figure stuff out on my own with it but i may come back for some guidance! Cheers and thanks again for sharing your knowledge! Phil

-

Hi Alan, Yeah I think both of you are right, he doesnt known the terms but he described it and its a single action, it can only apply force in one direction. And its the bottom die that moves up to do the squishing (hammer die) and then comes down by gravity. I don't know if it really matters where the hammer die is.. Frosty i can picture perfectly what you mean by manual action effectively making the stroke restart right away when you hit the pedal.. so its not going all the way up (or in this case down..) so manual is ideal in this situation. So he said he would part with it for 250 bucks. At the end of the day, what do you guys think? Im prepared to spend the money on if you guys think it will work, ive found a few 10000 psi power packs for 300 bucks.. Cheers Phil

-

So.. Contacted the guy and made an offer, he accepted but asked what i was going to use it for and he said it wouldnt work for me..its only a 2 way cylinder and not a 4 way and it's really slow, it takes a good 15 to 30 seconds for it to go all the way down so its not quick enough to work the steel while its hot, i might get one or to presses in, unless that was one of the things you ment by pimping it out Frosty? Cheers Phil

-

Ok good to know, ive found a few used pumps online for 250 or 300 bucks, but they dont list any info about the pump itself, ill have to contact them later in the day. So im assuming auto return is more expensive and the pedal would work fine and possibly be cheaper, is it as simple as just putting the pedal onto the line from the pump to the press and then thats it? I like what you said about having everything in the same stand, thats just smart, I am definitely going to do that! Ok, by that you mean an 8hp fuel powered engine/motor might not need an 8hp eletric motor? Ill do some more research into differances and such. My wife gave me a go ahead to make an offer on the press, I figure I jump on it now and then wait for a deal on a pump, the landlord is building a new bigger shop in the spring so im in no rush to get it finished but it would be amazing to have. Thanks again Frosty Phil

-

Wow ok thanks guys, good to know! He said in the ad that he doesn't have the pump for it but im sure it would be fairly cheap to acquire? Im assuming probably somewhere between 200 and 400? If it means having a working forge press for under 800 bucks sign me up! How complex are the controls? Ive never used one but im just assuming it has two actions with one lever, one is to squish and the other to not squish? One might make there own controls for a cheaper cost? Again im ASSuming so i might be making an ass out of my self! Cheers Phil So after posting that i did some quick research, the thomas and betts pump system is almost 4000 brand new, and i saw a used one for 700, i will keep looking around and see what there is..any reason i would want/have to stick with the same brand? I could potentially get a similar pump for cheaper? Again im new to the game of hydraulics, i mean ive used machinery on the farm all my life like loaders and such but nothing like this... Cheers x2 Phil

-

Hello all, forgive me if this isnt the right place to ask this by I myself had never intended on purchasing a press until i found a 40 ton hydraulic crimping press on facebook market place today for 350 bucks, now i know what its used for but no idea how it works, is it something that could be used as a forging press? Its a Thomas and betts press model # 21940 . I tried looking for info online but all that keeps coming up are diy presss, and i figured one of you fine folks might know alot more than me Any help is appreciated, or go tell me to jump off a cliff Thanks Phil

-

Thanks Frosty! I found the Peterson's stuff on amazon for 55 at 1 lb so that is doable, Ill get it next month in my next statement and we'll see how it goes! Cheers Phil the welder

-

Thanks! I figured it would be good practise trying to make the hex type shape.

-

Frosty, to be honest it's a couple of things, I've only had the forge running for 6 hours total so I'm just beginning to learn hammer techniques and get that better, and I'm making tools I know I will need like center punches and chisels. Lastly I guess I don't plan on doing any welding with it for at least a year until I have a firm grasp on the basics, that being said I understand the principles of how to do the welding and the steps, so I guess It wouldn't hurt to try just for the hell of it.. Just so I know it will do it. I have to get my hands on some inexpensive flux and I have no clue where to start...online? Farrier supply store that is up the road maybe? I don't see them needing flux though. About the vesuvius, I tried contacting the manafacturer but they were impossible to get them to call back and I couldn't find any guides online. I let it sit for an entire week before firing it.. But half way through the week a storm drove rain under my sliding shop door and soaked the one end of the Forge, so I peeled all that off of the end and reapplied the face,(it was so saturated with water that when it dried it was a really weird consistency that I didn't trust) then let it sit for another week, so technically the inner tube sat for 2 weeks For testing, should I mix it in say a paper cup, then once dried rip all the cup off and throw it in the forge? That sounded like alot of work, but I can just imagine how strong the finished product would be, definitely bullet proof! On the plus side at least I know my 1 inch burners were more than enough for my forge volume Just a pic of the chisel I made, my first tool I hammerd to 90% shape and then ground for finish, it started out as a little cut off of a RRR 1.5" square by 3.5" long Cheers Phil the Welder

-

Hello all I just wanted to post an update from the burners 101 thread to here considering I'm finished the forge... Well... Sorta.. I had some large set backs and made stupid mistakes, it runs great (I think..) but the longevity of the inside castable wall is definitely in question.. So this is after 10 minutes of warm up at 15/20 psi just to get up to temp and then it will run at about 8 psi when the burners begin to slightly jug.. I get a bit of yellow dragons breath if I'm running at 8 psi but alot less if I run it at 12 and up which doesn't make sense to me Frosty, I took your advice and filled the void on the bottom floor, I used hard fire brick but I still used 3 inches of the kaowool in the main body and just 2 inches on the door (there will eventually be a door at the front with a small cut out) This is after 15 minutes of both burners running full out at 20 psi, I'm pretty sure it's welding heat but because of my lack of experience I'm not close to testing that theory by actually welding, once it's at this heat I can maintain it with one of my 1 inch burners at 8 psi no problem. This is the same but just a differant shot with the back door closed and a brick in the way to impede heat loss. Here is where I hit a bit of snag... So when applying my vesuvius refactory it would not spread easily at all and even with the blanket rigidize it started to take it apart on application think hard butter on cold toast (I was also using a gloved hand as I misplaced my trowel, I should have just bought one but I was impatient) so I had the GREAT idea of mixing the refactory with a bit of water to make it easier to spread, it worked but here is a picture where you can clearly see the refactory bubbling in many spots Then there is all the cracking inside which I assume is from uneven application (tried to stay at 1/4" thick but it was tricky) as well as the added mix of water, and now the whole thing looks like tectonic plates covered in bubbles... Here you can clearly see the 1/8" or more wide cracking. This picture is also taken 15 to 20 minutes after shut down so it retains its heat well (I think) So.. What do you all think? Should I just trowel over the cracks (found my trowel) with the non water mixed refactory and that should do or would someone recommend I pull each "tectonic plate" off inside until the first layer of kaowool is completly exposed and apply a whole new layer? Any advice and criticism is greatly appreciated! Ps.. I know it's still too big Cheers Phil the Welder

-

Newly built 2x72 grinder need belts

Bearded Welder replied to ironwoolf's topic in Grinders, Sanders, etc

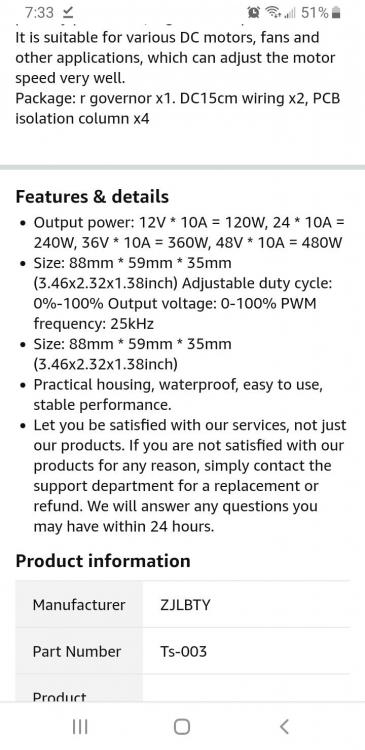

Ah yes I think that might be a problem, so I just need the same kind of controller but with the same rating or higher as the motor? -

Newly built 2x72 grinder need belts

Bearded Welder replied to ironwoolf's topic in Grinders, Sanders, etc

Hello everyone! So I looked all through the forum for possible info on this and I couldn't find anything so I'm hoping someone in this thread could help, or point me in the right direction, (I didn't know if I should start a new thread or not.. If yes let me know) I'm looking to build my own 2x72 grinder like yours Ironwoolf, and I found a treadmill motor online for cheap and I'm wondering if this controller on Amazon is plug and play? I have no where with all when it comes to electricity.. The motor with all the pertinent information And the controller I'm looking at Any guidance is greatly appreciated! Cheers! Phil -

Ah, ok so he is a sort of legend in the blacksmithing community I take it? I'll probably buy it off amazon, it'll be 20some Canadian but I'm sure it's chalk full of good things too read, that or kindle, I think my wife has one of those things. Thank you for the information! Much appreciated! Cheers! Phil the Bearded

-

Ohh... No, but that does sound oh so very interesting! What medium is that in? A book? Online source? Possible in the IFI?

-

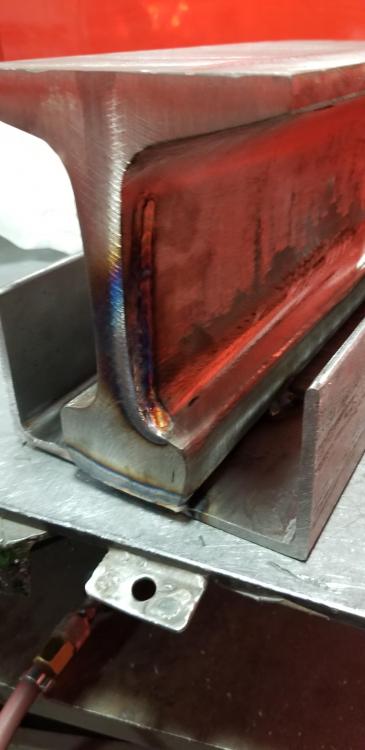

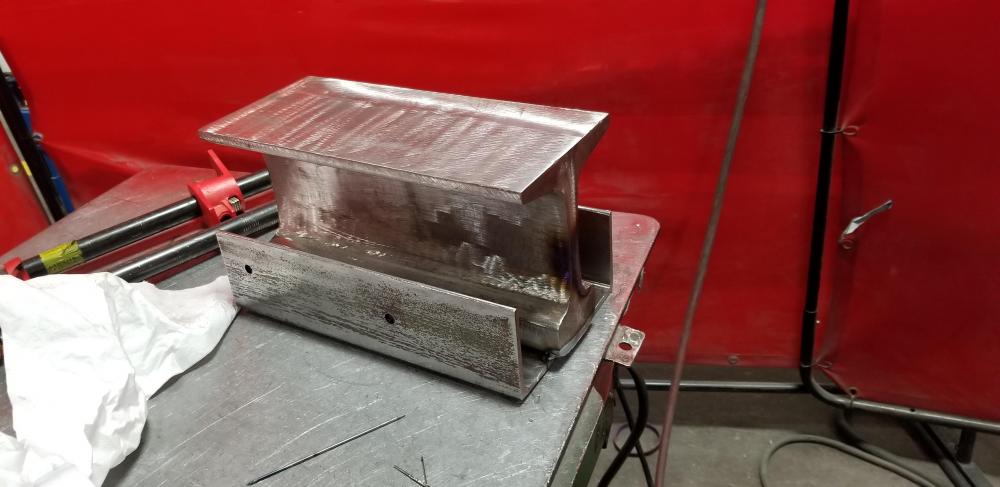

Hello all, I think this is the correct place to post my anvil in progress, if not let me know. Let me start by saying yes I'm a little nuts to spend this amount of time on this project, but I was on a budget and work didn't mind me using filler as we have alot of waste anyway.. It started out as a chunk of RR, and then I got this crazy idea to make a full sized anvil from it.. I still need to weld the horn, and heel and feet on, but after 6 months on all my breaks at work, after multiple passes of Tig welding it is finally almost done..total cost of material was 40 dollars, I bought some rod of high carbon steel off a guy to weld into cavity to speed up the process, but every square inch inside is all welded together, no seam welding or the like at all so no gaps to cause vibration. I know I will lose most of my hardness when I do my pre and post heat for the welding so I'm trying to decide if I want to risk re hardening the face but I'm not sure of the best idea, I might just go the route of work hardening it with an air hammer instead of risking a heat and then quench... Let me know what you think, as well as any ideas! Cheers! Phil The Bearded

-

Well thank you everyone for the terminology lesson, I'm going to re-read this page till that all sticks but definitely opened my eyes to what means what. Frosty I like metaphorical dangerous advice, it's alot of fun! But actual dangerous advice.. Not so much Cris, I'm probably just as green as you! The little orange fllickers you're seeing occasionally are probably flecks of debree from the nozzle, grinding dust, particularlets from an abrasive pad or cut off wheel, they go away after a while. An orange fan at the end of the burn being constant is more propane in the ratio than oxygen I'm pretty sure. Cheers, Phil the Bearded

-

So oxidizing means too much oxygen, which I took to mean reducing? Do I have the terminology mixed up? On that track rich would be propane rich I assume.. I looked at the picture in better detail and now see a tiny bit of green between the primary envolope and the "tertiary" envolope, is that what tells you it's reducing which I'm now understanding means reduced oxygen and more propane...? Sorry to hyjack your post Cris J, I shouldn't have commented about your pictures until I have a better understanding of what I'm looking at, my apologies.. Phil the Bearded

-

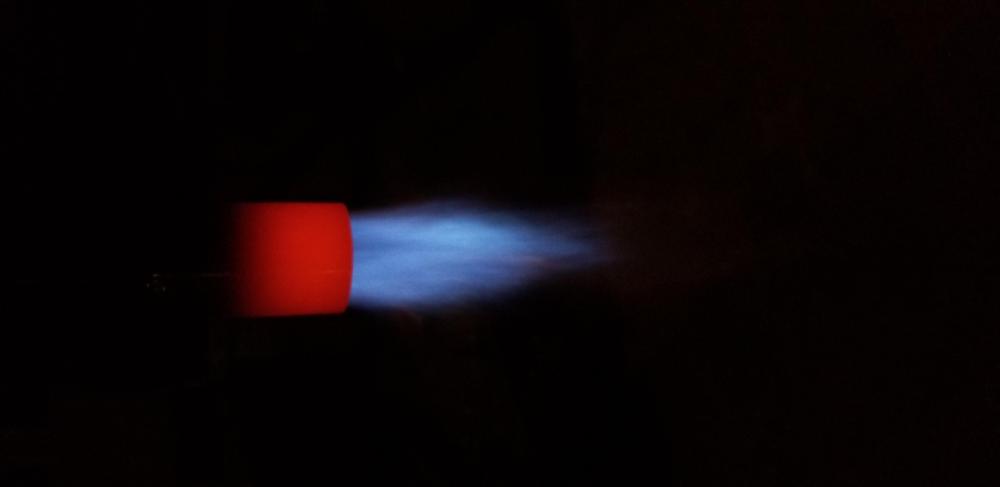

I don't know if this is acceptable for me to critique as A, I'm pretty new and B, this is Frosty's burner, but I would like to take a crack at it. Forgive me if it's not. Looking at your flame.. If I had to guess I would say it's a little oxidizing, I see purple on the fringes and white in the center, ideally you want no white and a deep blue hue..now I could be seeing it completely different in the picture compared to what your seeing in person because of what the camera does. Also it's hard for me to tell but it sort of looks like your ratios on your T are off..? I think Frosty's design for a 3/4inch burner has 1 inch air openings... Again it's hard to tell but it looks like your openings are bigger than 1 inch or your burner tube is smaller than 3/4inch..again I could be wrong. Since I'm new I would definitely wait for the greater knowledge of the others here, especially Frosty since it's his Design. Again forgive me if I shouldn't have added my 2 cents. Cheers! Phil The Bearded

-

Mikey A great analogy if I ever heard one! Thanks for the tip! Cheers! Phil the Bearded

-

Too funny Frosty! I have actually followed all those differant designs in this thread and it's all very interesting to me. I think it made a differance in my burner but positive in some ways and negative in others.. maybe made the burner slightly unstable do to mixing speed possibly? I might try and lengthen the tube to see if that settles it back down, I know I have a good base model to go from, but I can't help trying to always make it better... I'm sure nobody here ever feels like that..ha! Thanks! I might just add visual design into my criteria from now on So then my crappy hard fire brick might work a treat then, the wife will be glad to see me get some use out of them after she found out the money I spent on... Well... Basically fancy rocks because I found out later, unless you want to forge a pizza, they are basically useless.. True words Mikey.. Not everyone has that welding fan belt for instance.. Cheers! Phil the Bearded

-

Frosty, you can call me Phil, of course that goes for anybody.. I could try and get my hands on some plutonium! That would really give me an edge I think! and I thought added swirl would be a good thing? Trying to mimic the concept that I read on the thread of the vortex burner but in just a differant way I guess.. Maybe I'm over doing it a tad? G-son, you idea of a cheaper insulation had crossed my mind but I'm not sure what kind of insulation could go on the exterior of the kaowool between it and the shell.. I'm assuming R14 pink panther won't cut it? Is there a cheaper less heat proof variety of ceramic blanket? I know of 8lb and 6lb and what I have is 8, but the price differance is negligable in my findings.. Thanks Phil The Bearded

-

So this is my little contraption to initiate a swirl at the top of the intake reducer.. I think it's working but I need to change something else to make it work? This is only a prototype/concept, if it's viable I would make a more thourgho setup with properly placed I let's and the such. Thoughts are much appreciated! Cheers! The Bearded Welder