mARTin Metal

Members-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by mARTin Metal

-

Norton #10 Flypress manual, specs, Weight etc.

mARTin Metal replied to mARTin Metal's topic in Presses

Thank you sir. -

I found a number 10, Norton Flypress. I’m looking for info and support documentation. On specs. Etc. I have not had any luck with an internet search. Thank you in advance. Any referrals would be appreciated.

-

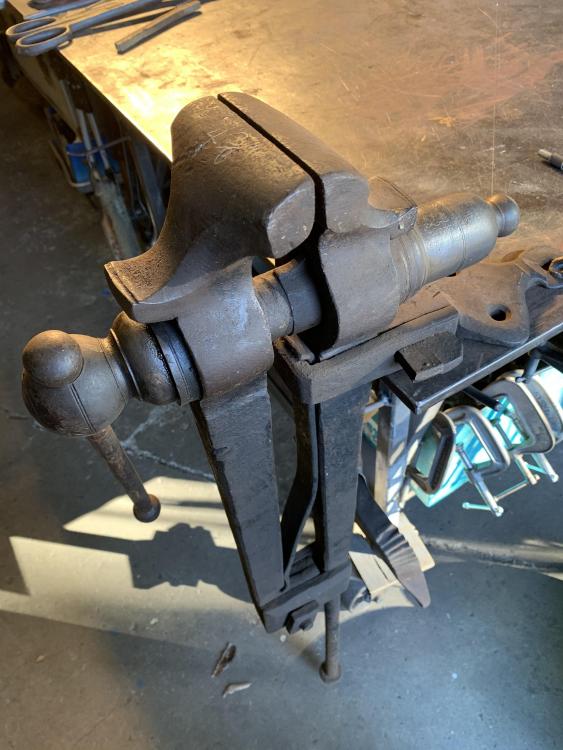

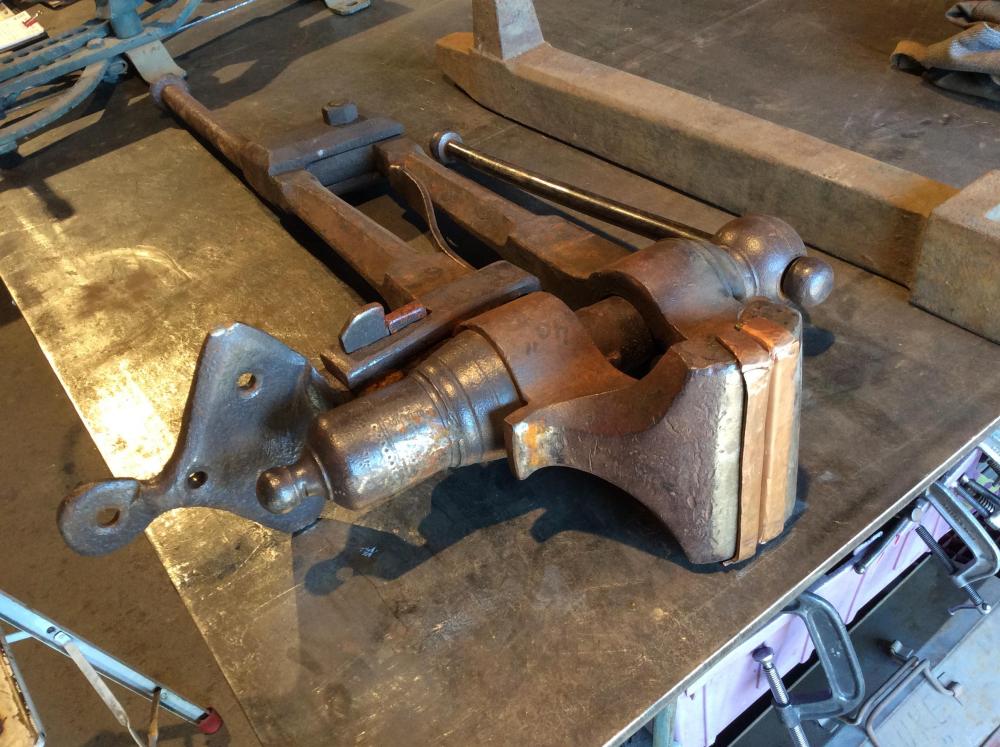

So, lucky me. If you hit enough estate sales your bound to find treasure. Paid $200. For vise and all items pictured. Love the ornamental lines and detail on this Peter Wright. Excellent condition. Complete. No visible signs of abuse. Threads have full profile. Looks to have been parked and unused for decades. Thread box marked with maker, but some style of ornate logo in center of maker I.d. Note that the legs are not chamfered. My question is regarding age and provenance. Any historians wanna make an educated guess as to age?

-

Why does content need to be approved by a moderator.

-

I met a smith who lost his home and shop in the California wild fires. Depending on the location of the tool in the fire, what might be the expected damage to the steel with regard to tempering or annealing? Anvil on a burned stump, hammer heads with handles burned off. Tongs? What might be the general consensus on “repair or re tempering”? Fire survivor Anvil and hammer heads? I’m thinking it really depends on the temp and duration of exposure in the fire. Would the hammers and anvil be softer as a result of the heat? He might need to straighten the reins on the tongs, but I think they might be ok. Any thoughts or recommendationS.? Asking for a friend. TIA,

-

I just picked up a 4” warren tool and forge, qwik werk vice that I would like to build a collapsible stand for travel. I saw a previous post with a suggested design, but now I have to re find it again. Anyone have any experience with this design. I think the picture I saw had three legs that swung up inline with the post, hinge pins at bottom of base.

-

Anvil identification please.

mARTin Metal replied to mARTin Metal's topic in Anvils, Swage Blocks, and Mandrels

Darn. Just sold out from under me. Still, a strange make and model. Thanks Thomas, i only had the one picture and was unfamiliar with the shape of the foot and the solo Pritchett hole centered in place of the hardy hole. At this point, since the Anvil has been purchased by another party, now I’m just curious about the brand. I’ve used the rebound test on my working anvils. I’m getting close to 100% rebound on first bounce, then 95%, 90% etc. hard to measure a moving object. Now imagine holding a camera set on slo motion capture, a tape measure and dropping a large ball bearing onto slightly uneven surface, then catch the ball bearing before it shoots off the side and rolls under the drill press. Rebound test should be performed by a circus juggler. -

I came across this ad for an Anvil with misc tools for $200. I have not seen and Anvil like it. things to note in identification, with this only photo, no numbers, size or brand. Looks to be about 100# or less note narrow base or foot. single oversized Pritchett hole in place of hardie hole. looks to be cast with horizontal casting part line and hard face top forge welded on or in casting? anyone seen something like it? Darn. Just sold out from under me. Still, a strange make and model.

-

Thank you Thomas, I enjoy hearing from you. be well, we need you.

-

Iron dragon, that’s a good idea! I made my stand to fit layers of Marine grade plywood. So I can adjust the height for different users. I’ll “glue” ( removable) to one layer and use one or two plywood layers for height. I’ll have to make my holdowns adjustable. The Anvil is only 80# so it is a bit lofty in full use, but with the holdowns sandwiching the dense plywood it might work ok. Thanks, I’ll give it a try.

-

Thank you Thomas Powers and Iron dragon, your help and advice is much appreciated. I have worked in both Foundries and Forges, not my first job nor my last. Reminds me, someone told me “All Farriers are blacksmiths, but not all Blacksmiths are Farriers” I used the term Foundry as a ubiquitous term for Forge, when I knew there is a difference. Let’s not bring up “Smelting” It’s best to use precise terminology when seeking answers. Something else I am working on. Thanks Thomas.

-

Yes I do, thanks Glenn

-

Columbus iron and forge, good tip. I’ll check it out. I have found ear protection to be the best sound suppression. I’ve tried magnets that deadens the sound well, but the slag sticks to the work face. Chain adds more weight and reduces ring, but gets in my way. thanks for the reply

-

thank you for your reply. I’m located in No. California. Prices are high out here. Thanks to a resurgence in the craft. I wanted it for a traveler demo setup. It’s in good condition and I can repair the few small edge chips. I’ll try to get a look at the Anvils in America book. Thanks again,

-

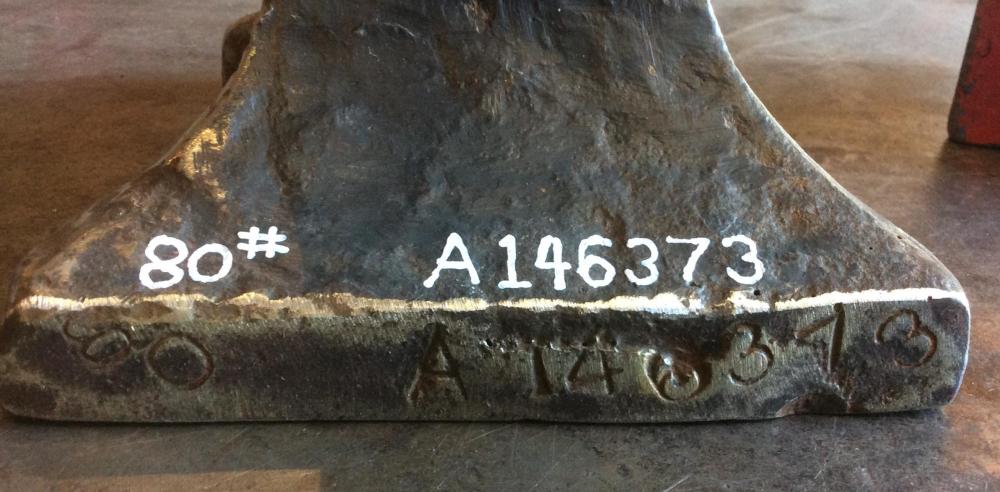

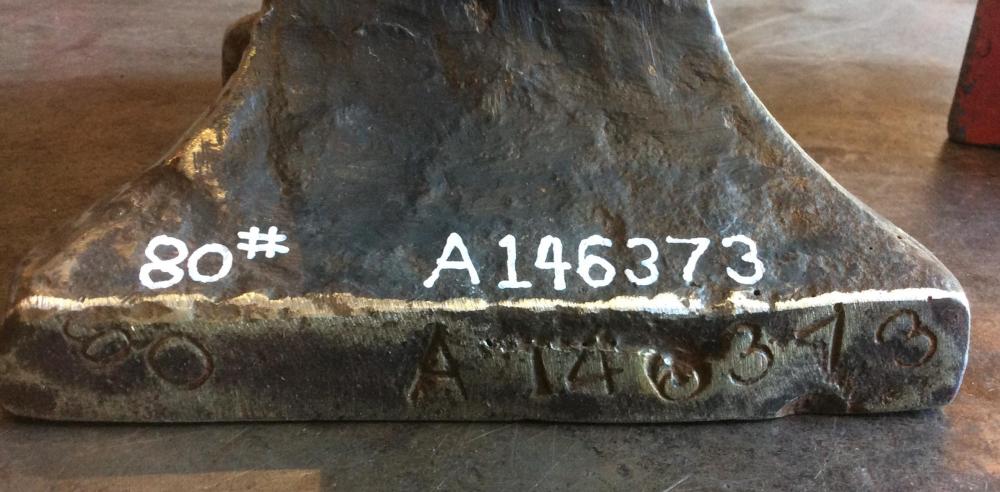

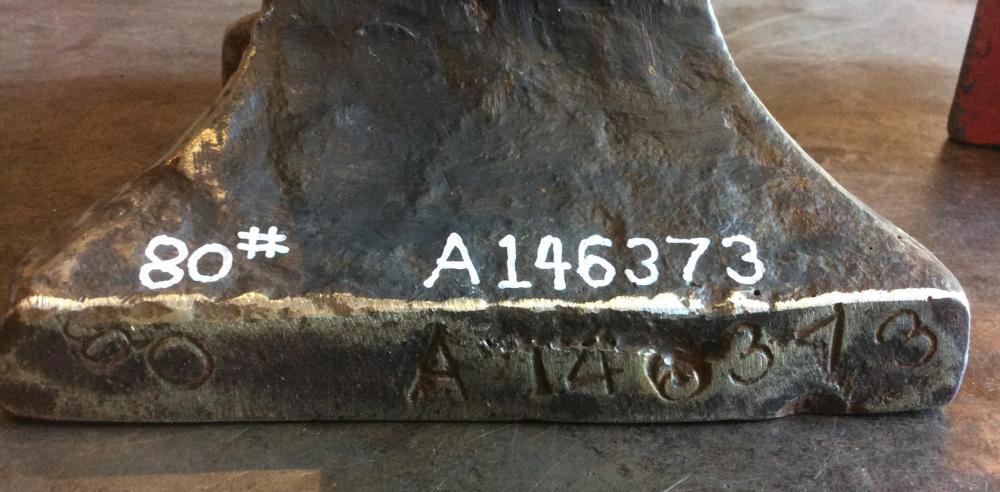

I have always found the blacksmithing community to be supportive and encouraging. My mentors have been generous and forthwith in all matters. With this in mind I am appreciative and grateful for our community. I turn to the internet for immediacy and reference often. My quest for provenance requires patience, I’m working on that. I have seen members with 34,000 posts answer questions and make referrals in less than an hour. So I post my inquiries here, with good reason and with a reasonable expectation. I posted a question with documentation and was sanctioned, I’m guessing due to my impatience and innuendo.please accept my apologies as I would like to continue my exploration of our craft and vocation, with temperament. That said, I was purchasing an Anvil and wanted to know how old it was and who made it. I bought this tool for work. My obsession with historical facts are based on curiosity only. I can see that it is well made and will suffice. What I do know is it is 80#, with an ACME stamp. I have sourced info that referenced ACME Anvil where made by other foundries for the Sears Roebuck catalogue. One was Trenton. Co. Given the serial number provided, would anyone care to cross reference or make referral where I might find out the age and maker? i will not be checking this thread every hour as I have made the purchase based on info at hand at the point of sale. I did not explain my predicament or the urgency. Again, my apologies if I have upset anyone.

-

Sorry to bother, the serial number question. Not important, just curious about the age and make. I must have the wrong group. I’ll check with Anvil Fire.com,

-

I payed US$400. For this 80# ACME. I thought it was good condition. What can you tell me from the serial #? Is it a Trenton for Sears Roebuck? Age? their is a “U” under the tail. Inspectors mark?

-

This is my eighth vise acquired through a series up horse trading upgrades. One after another, restored and put to work. Each one bigger than the last. I’ve never had more than two at one time. Space permitting. I buy low and sell high in order to outfit my shop. I wouldn’t say vises are my vice, but I admit to and extensive hammer rack. I use the same three every day. Anyway, this thread was intended to get some input on pricing a very good condition 5-1/2” Peter Wright. On the internet of all things I have comps from $300-600. I’m not looking to get rich, just leverage my next treasure. One thing is certain, prices are going up. Thanks to television and the resurgence of the craft. In ten years all the hobbyists will be selling. My shop is complete. Moving on to another thread. Thanks for your input.

-

Thanks Kozzy, my hope is an experienced buyer will know the difference between a Colombian and a Peter Wright. Up next to each other should make my point. That would be the design and style. If the jaws are parallel, the screw or thread box is not stripped and the handle not bent from cheating, I’ll take the peter Wright hands down. Even pay a little more. I have never given a vice away for $75. I have sold a beautiful, perfect condition, 4” Peter Wright, cleaned, sealed and on a nice looking base for $375. The buyer was ecstatic! Matched his Anvil. but I did all the prep work, ready to go. one mans junk,........ i keep tellin my scrapper, no junk today.

-

Thanks Kozzy, paint and oxidation. It does look wavy, just a bad pic. The foundry does not do much finishing work beyond gate, spur and part line grinding. i think I’m going with $700. Or best offer. With offers taken til a set time. That should separate the serious-not serious buyers and force a bidding war at zero hour. I can only hope it will be be a gentlemen’s auction. Ive been disappointed, sad but survivable.

-

Both, I’m taking it to California blacksmith association tailgate fri-sun. Pricing for these is all over the map. Here on The west coast there is a booming interest in the craft and regional market value is higher.

-

Good day, I'm tryin to put a price on my vintage 5-3/4” Peter Wright, stamped on the thread box, post leg vise. It is 42” tall and 87 lbs. the condition is good. Threads are in good condition and the handle is straight as in not an abused tool. I did replace one wedge. I am in Northern California and we don’t see too many large vices come up for sale. I would like to here from dealers in this region as to value. I often pass on deals outside my area due to shipping costs. Fair value and within driving range is key for myself. thank you in advance for sharing your thoughts.

-

Greetings, i have a mandrel I’m trying to put a price on. I realize location and availability are driving forces, not to mention shipping. So, here are the factors; I am in Northern California, the mandrel is 42” tall x 13” at the base and 3” at the top. It weighs 215 lbs. it is a 1” thick casting. It has no mounting flanges, no tong groove. Clean surface. Aside from shipping, buyers responsibility, what is a fair and reasonable price? Thank you in advance,