Potato-Demon

Members-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Potato-Demon

-

I’ve actually got a couple leaf springs from a semi. Way too thick for a knife but I could just draw it out until it’s thin enough. Sorry about the late reply, this week has been a little crazy.

-

I just shortened the title, thanks for pointing that out.

-

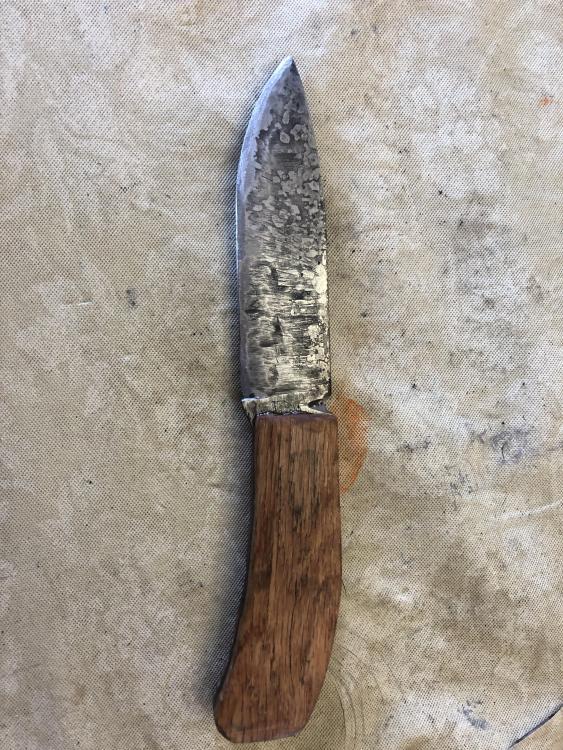

I’m not very good at making knives so I always like to practice a design by first making it out of mild steel. I then make the “good” version from o1 or whatever. This particular knife is my second stock removal knife. The handle is oak with hidden steel pins and the blade is some mystery (probably mild, it doesn’t stay sharp long) steel I bought at a hardware store. This was my first time doing hidden pins. I didn’t bother polishing the blade much because I liked the look. I did a pretty bad job on the bevels.

-

What did you do in the shop today?

Potato-Demon replied to Mark Ling's topic in Blacksmithing, General Discussion

I guess that cavemen probably used two rocks to do it... What I meant was it’s difficult for me to do much with limited tools and not much experience. -

Knife I made for a friend for Christmas

Potato-Demon replied to Potato-Demon's topic in Knife Making

I wouldn’t have used rebar if the knife I was making out of an old spring hadn’t cracked without enough charcoal to restart but enough for a quick one so this also meant I was super rushed. I’ll try to do better next time. I sharpened it before the heat treatment to reduce time spent filing but I believe I put some ok bevels on it but as you said, they’re hard to see. Man, do I need to buy a belt sander and bench grinder... -

What did you do in the shop today?

Potato-Demon replied to Mark Ling's topic in Blacksmithing, General Discussion

I would do other stuff but I don’t have a proper anvil so I’m limited in what shapes and stuff I can make. Makes sense, I’ll try some more fire pokers I guess. -

I was cleaning my workspace earlier this week and I found a piece of rebar under my anvil stand from my failed attempt at making tongs. I needed to get my friend a Christmas present and I know he likes knives so what happened next is obvious. Took about an hour or two (not counting the time in the oven for tempering) total of work to do. This is my third knife and I think it’s better than my first and failed second attempts. The reason the blade looks cracked is it wasn’t cleaned off completely in the photo. I wish I had an anvil with a hardy hole and some hardy tools; it would have made bending the handle much easier. The tip was purposely not worked much because I didn’t want to screw it up with barely any charcoal left and Home Hardware closed for Christmas. This wasn’t meant as a heavy-use item otherwise I’d have made it from one of the HUGE leaf springs I got for free. What do you think of it?

-

What did you do in the shop today?

Potato-Demon replied to Mark Ling's topic in Blacksmithing, General Discussion

I made a knife as a Christmas gift for my friend out of a scrap bit of rebar I found under my anvil stand. I managed to bend the handle using a vice and tongs (I don’t have a proper anvil so I can’t use hardy hole tools). The bottom of the blade isn’t cracked, it’s just dirt. Third thing I’ve made and I think I’m getting slightly better, any advice is appreciated. -

My first knife

Potato-Demon replied to Potato-Demon's topic in Knife making Class General Class Discussion

By forge welding it on the edge? I’ve been trying to find some coil springs but so far I only have leaf springs and a whole wheel barrow full of low-mid carbon steel scraps. That knife looks really nice, I especially like the handle. -

My first knife

Potato-Demon replied to Potato-Demon's topic in Knife making Class General Class Discussion

Would a couple of HUGE leaf springs be any good? I got them for free from an automotive place. Some rust but not too bad. I need to order some steel but I haven’t gotten around to it yet. Good idea about the bolt. -

My first knife

Potato-Demon replied to Potato-Demon's topic in Knife making Class General Class Discussion

I guess it was pretty rushed. I was only doing it to test out the forge and the whole process besides the heat treating only took about an hour and a half. Would a bolt used for joining pieces of track together have more carbon than a spike would? -

My low-budget setup

Potato-Demon replied to Potato-Demon's topic in Blacksmithing, General Discussion

Where I live I can only find cheap hammers. Off to amazon I go... -

My low-budget setup

Potato-Demon replied to Potato-Demon's topic in Blacksmithing, General Discussion

Ok, thanks. -

First project I’ve ever done other than some fishhooks. Made this out of a high carbon (I know they aren’t actually high carbon but they’re better than just plain spikes) railroad spike. The edge is a bit uneven because I just sharpened it with my Dremel. Gonna fix the edge later tomorrow with my mill file. Heat treatment is done. I heated the blade to non-magnetic and dunked it in a can of cooking oil. I put it in the oven at around 400 Fahrenheit for an hour or so. It seems to cut well but it’s not exactly the best knife. I don’t have a belt sander and my angle grinder is screwed up so I can’t really clean up the knife too well. I kinda like how it looks now though. I’ve started on a tomahawk from another spike now and I expect to be done it in a couple days. Man are these things good for practicing.

-

My low-budget setup

Potato-Demon replied to Potato-Demon's topic in Blacksmithing, General Discussion

Ok, I’ve got an old pallet and I’ll put some more reinforcements in tomorrow, never noticed any bending but I guess it could happen over time. How heavy should my ball peen hammer be? I’ve been using a 12 oz one right now. -

My low-budget setup

Potato-Demon replied to Potato-Demon's topic in Blacksmithing, General Discussion

Thanks for the advice! I’m looking for a good 2 pounder currently, any recommendations? -

I’ve been interested in blacksmithing since I was 9 or 10 years old. Around a month ago, I finally finished my forge. I’ve had my anvil stand done for around 2 months now. I mostly just use a 3 pound sledge I picked up at a flee market for $5. I don’t normally have the stand this close to my forge, I was just doing this so you could see it a bit better. I weighed my “anvil” and it’s around 50 pounds. The thing on the side of the stand is a railroad spike hammer head. I use it to round metal. The forge is a sink lined with firebricks and sand. I usually put a cookie sheet on top to trap the heat in a bit better. I use a hairdryer as a bellows. Thankfully, this setup is pretty cheap, even unemployed 14 year old me can afford it!

-

Show me your blacksmith pets

Potato-Demon replied to Glenn's topic in Blacksmithing, General Discussion

My black cat named Rascal always stares at me through the deck door when I’m pounding on hot metal. I’ll take a photo the next time he does it, my neighbors get xxxxx if I’m blacksmithing past 7... -

Just read it and some of those are really neat. I have access to railroad scraps, and loads of them, so I will try and make more anvils for different purposes. I guess I’ll need to go and buy some disks for my angle grinder...

-

Ok, would something like this be good for making bends and holes too? I also have a tie plate that I could use as an anvil too. I’ll modify the stand accordingly and turn the main anvil around ASAP, good idea.

-

Thanks, I’m actually just about to go out and get a smaller section of track to do just that. I made the stand so I can remove the anvil and put a new one on as needed.

-

This is my anvil that I got for free from the railroad tracks near my house, it was just lying there gathering rust. It weighs about 30 pounds. The anvil stand is made from both scrap and store-bought wood.