-

Posts

46 -

Joined

-

Last visited

Profile Information

-

Location

N.Indiana USA

Recent Profile Visitors

-

Hardy tool making

Chuckbuckeye replied to Chuckbuckeye's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Thank you gentlemen ! While I would love to throw it back in the forge I’m a bit worried I went too far . I get a pic in the am . I bent it over pretty good in frustration. Thank you for all the help you guys are awesome! So much smarter for my next go at it ! Thank you all! -

Hardy tool making

Chuckbuckeye replied to Chuckbuckeye's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

That’s a great idea and your right very obvious ! Wish I would have known ! Lol now I just have to cut and grind a cutting edge on it now . I will use this tip next time for sure ! Thank you! -

Hardy tool making

Chuckbuckeye replied to Chuckbuckeye's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

Oh geez I don’t remember . 30-45 min I had the forge going good for a bit and had it sitting next to the fire . -

Thanks frosty ! That’s a lot of info and he hit the nail on the head so to speak about the hitting to hard . That’s exactly what happens . I’ll try again a little smarter this time . Lol thanks again! I’ll be looking up videos again for sure

-

Hardy tool making

Chuckbuckeye replied to Chuckbuckeye's topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

I’m using a break rotor forge and coal. I did try and move around the anvil and stoke in different directions trying to fix it but it ended up almost buckeling on me so I let it cool and stopped on it for the day . -

Hardy tool making

Chuckbuckeye posted a topic in Hot Cuts, Anvil devils, metal cutting on the anvil.

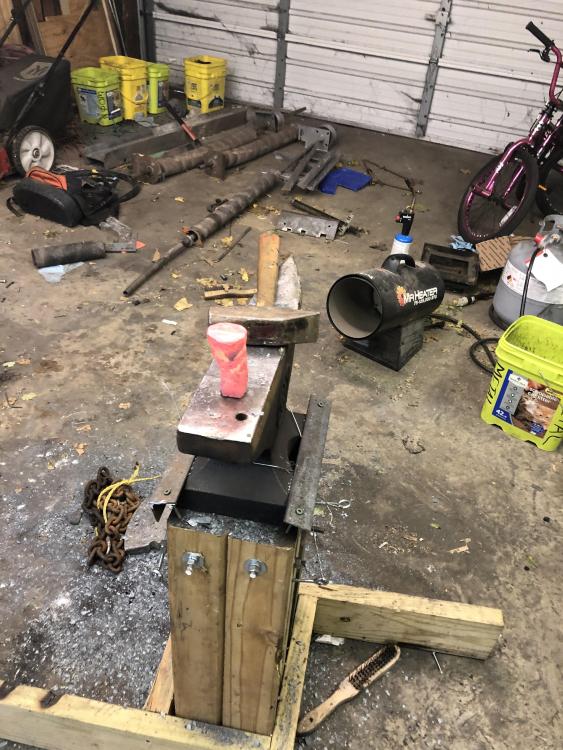

I Reid to make a hardy hot cut today our of a huge bolt I found . Didn’t end badly but I got a lot of work to do. But I had a problem with it wanting to bend in one direction as I as upsetting it . I tried to work it back and forth but it would barely move even when it was yellow . Any suggestions for my next attempt ? -

So I tried to forge weld for he second time today. I was feeling really good about it from the first pic but then on the second pic I was disappointed to see it coming apart . I tried to weld it 3 times and used a XXXXXX ton of borax . Still wouldn’t stick . So I decided to go with it and make something decorative . Can anyone give me any tips on what went wrong or why I couldn’t weld it back ? I had it sparkling and it just would stay . I grinder the metal where I tried to make the weld . Still wondering what went wrong .

-

we’ll im trying to make tongs and wanted to do it like the videos . Not sure my terminology is correct but I wanted to punch a hole while it’s hot . So I can try my hand at that and riveting all in one project . I have a lot of rr knives but trying to do different things . Thank you Thomas for the quick response !

-

I have some 1” rod of what I think is 5160 . Is this a good metal to use for punches or drifts ?

-

Thank you guys ! I will be disassembaling those later today . I’m hoping to use the wheels to use on a hammer of some kind maybe a leaf spring hammer .

-

What did you do in the shop today?

Chuckbuckeye replied to Mark Ling's topic in Blacksmithing, General Discussion

Das you make some awesome stuff ! Very nice ! -

So I got some garage springs today . I’m wondering if this is like all the spring metal I’ve heard about that you can make tools from. Is that the case with these . It’s not as thick as a coil spring from a car but I have a lot of it .

-

Why does my Vulcan 8 also have a 2 on it ?

Chuckbuckeye replied to Chuckbuckeye's topic in Anvil Reviews by brand

Free is the big word for me right now . Lol cheap will work but free is......well free . Lol -

Good point . I’d like a variable speed motor but a waste gate or something similar would work too.

-

Why does my Vulcan 8 also have a 2 on it ?

Chuckbuckeye replied to Chuckbuckeye's topic in Anvil Reviews by brand

Ok thanks ! I’ve worked on a lot of this type of fan . On a much larger scale . I’m talking like 3’ to 4’ in circumference . Have not yet got my hands on something I can use at home . I’m doing as much homework as I can on this as the smoke is really bad in my garage . Probably go this weekend and get something in . I was just really hoping to find something for free.