-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by RogerrogerD

-

-

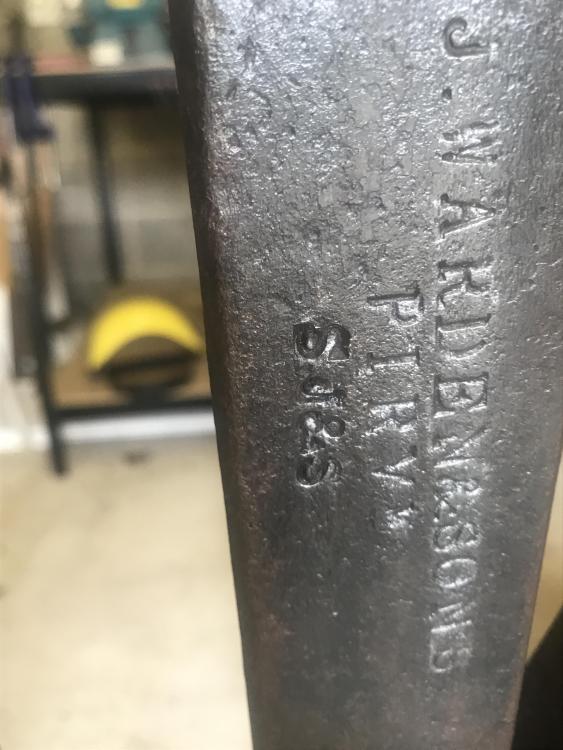

Just picked up a nice 6 1/2 “ leg vice and a No 15 Bradson pillar drill. Both not functioning but 5 mins work in them and I've spotted the issues. The pivot bracket on the vice is seized up preventing the jaws from moving but a swim overnight in wd40 magic juice should fix that. Its the one on the floor. The pawl spring was missing on the pillar drill but otherwise apart from rust and grime all working. Heres the pics . The pillar drill has a 50” dia flywheel and stands 2 1/2 feet tall. On the vice there is no thrust washer - can I ask advice from those here if I need one?

Feeling pleased with myself £70 the pair, and plenty to keep me busy these long winter evenings

-

OK I spark tested my “soft” anvil. Its definitely cast mild steel. So I appreciate everyone’s useful input. Because I already have a big “hard” anvil, I’m going to leave this soft, use it as a cutting table, and also semi permanently mount my “smithin’ magician” in the hardy. Welding up a hard face is bit beyond me and I don’t need a second hard anvil, so its luxury. Makes me wonder what was going on in that east european factory that I think was making Branco anvils on a sub contract. Looks like a Branco “blacksmith” anvil. Just for interest does anyone know if these go against the modern technique and do actually forge weld a carbon steel top on? Or is this an anomaly and why it was maybe abandoned.?

-

Fantastic effort Catropheus. About 40 years ago I was working in a steel foundry in your country...sorting scrap! and learned to weld there.

-

Great suggestions all. Thanks everyone. It came from a disused factory, a pile (!), that perhaps had been abandoned before finishing. In truth I’m coming round to the idea of leaving it soft - I have a very big, very hard anvil so going to the effort of hardening it, is interesting, but I don’t have the kit or the imperative. I’ll spark test tomorrow and report back .

-

Ah yes , of course. And Just forget its anvil shaped and use as one of those square striking anvils

-

I already have a magnificent 5CWT John Brooks anvil. But a family member has just presented me with a “new” 50kg eastern European anvil, that came from some factory. Looks nice enough, but... it’s awful soft. I think it came out of the factory before having a hardened steel top face forge welded on it. About a 20% bounce with a ball bearing and the ball bearing leaves an indentation even. Yuck. So while I’m grateful for the thought, I’m trying to repurpose it. It has a 3/4 inch hardy hole which is fine, I can use it simply for holding hardy tools. But what else can I use it for? Is it feasible to cut channels in it with an angle grinder, file them off into an ad hoc swage Block? Will it be too soft for that purpose? Drill it to make a monkey tool? Form some rivet headers? It feels like sacrilege, but it’s simply a big block of soft mild steel that cost me nothing. I doubt it would be worth the £ of finding someone to put a face on it. Maybe it’s just a big door stop for my workshop, but any suggestions gratefully received.

-

Great advice Mike, thank you. I take all your points. As I become more proficient then perhaps I’ll adjust driven by the number of tools or other parts of the process. For me, now, I find the wheeled trolley gives me more usable space, not less. Where it lives while I’m forging isnt the place it is when I shut up shop, or when I’m doing something else - but it can be in a second.

As a recent retiree from business, I love your comments about Six Sigma applications. Great stuff, and very valid.

As an aside, the design and fab of the tool rack is probably the first thing I have physically “made” in oh, 35 years or more, beyond the coathooks and bottle openers I am making as I start my smithing journey. A military career followed by a business career doesnt often result in such tangible, personal end products, so that’s a thrill. One of the beauties of being retired is the time to learn new skills, and I learned plenty of new lessons and remembered long forgotten ones, by doing this simple project from scratch, in slow time, by making mistakes, then resolving them, or living with them, as I put it together over a couple of days. Adapting as I went along driven by my limitations in terms of welding or whatever. As well as the pleasure of making something simple, stretching my mind in new directions is such a contrast from a working life of running a business. Thinking in three dimensions is new to me, and working out a process has been rather like solving a puzzle. There’s something enjoyable about working these things out from first principles (if thats what they are). The lessons learned in this first project, no doubt trivial to many, have been a joy to learn the hard way. No doubt as I progress with smithing or simple fabs like this I’ll learn less and less each time, improving my process each time.

Then, to burst my pompous balloon of self worth, I show off the trolley to my spouse. She blinks... and reminds me there’s a shelf in the bathroom that needs fixing, if I’m getting all clever with my hands these days. ;- )

-

Newbie here. Like many I have to squeeze my blacksmithing stuff in with all the other the detritus of life that ends up in my garage/workshop. I’ve not been forging long, but got frustrated looking for the hammer I put down somewhere 10 seconds ago and the tongs that disappeared from my hand seconds earlier. So I wanted one place to order them, and it needed to move. This is it so far (don’t look at the crappy welds). I’ll probably build a shelf on the back of it for punches and stuff.

-

Thanks VaughnT, that’s good thoughts. I have looked again at them, and I’m pretty sure they aren't hammers, because by and large the handles are not robust enough. Good enough to hold it in place but not to swing it. They must be top tools, indeed I have another two similar here that have clearly been struck many times, both with that thin groove at the non striking end. The seller on ebay suggested they were thrown out from a French museum, but other than that he knew nothing. Your analysis that they aren’t hoop setting hammers makes sense too. The larger of the two tools in this image is stamped “Talabot” which I understand was/is a French tool manufacturer. It has model Number 49, but i cant find an old Talabot catalogue to get me further. I enjoy a good mystery! In time I’ll choose the most suitable and make a hot cut. I’ll probably keep the Talabot as is as a curiosity.

-

Thanks everyone! I’ll repurpose them, in coming months.

-

Ah, right, so, perhaps for turning square stock into round stock?

-

Newbie here, so this may be a silly question. I picked up a job lot of old “hammers” on ebay. One or two nice antique hammers, but a bunch of what I think are top tools. Here’s three of them almost identical each with a groove on the end. The groove is about 1 inch to 1 1/4 inch long and about 1/4 wide. Can anyone tell me what they are for?

-

Hey, thanks Lou!

-

I’ll look out for you Mr I D

-

Hi, I’m new. Mid fifties, early retired, Gloucestershire, UK. A long long time ago I was a metallurgist and now Im trying to do something creative in retirement. Picked up a 5cwt anvil for £200 and a 5” leg vice for £25. Spent a bit more on a new side blow forge from Mike Judd. Teaching myself, (with you tube and Alec Steele course!) for now, signed up for a weekend course in September in S Wales.

So far I’ve made 4 ropey brackets to hold some steel stock, and burnt my first bottle opener to a cinder, and got the time it takes to make a coathook down to about two hours. :- )

most important lesson learned... if you have a side blower forge using coke, and you stand facing the blower and you stick a bit of angle iron in to heat it up, beware, the blower will blow a fat lump of red hot coke up the angle of the angle iron, up your sleeve and aaaalllll the way up to your armpit before you know it. So stand to the side....

-

New here. I picked up this beast from a near neighbour, for £200. Marked up 5CWT, SB, JB

It was languishing in a flower bed. I think its a John Brooks, and I think SB = Stourbridge. Big 1 1/2 inch hardy hole. I have mounted for now on a trunk and cleaned it up.

condition is ok - some damage to the edges, so its had some use, but it’s so big I can find a clean spot easily. One spot on the face is a little damaged as if something white hot was left for too long. Lovely ring (fixed with a welders magnet under the pritchell) and a ball bearing bounces right back into my hand.

Anyone have a clue as to how old it might be.?

-

It followed me home

in Blacksmithing, General Discussion

Posted

Thanks TP. I intend to do just that, and have mostly got there, apart from the pivot nut and bolt which are tight. I’ll leave it in wd40 over night and try in the morning. Any thoughts on the need for a thrust washer?