Dewnmoutain

Members-

Posts

95 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Northeastern Wisconsin

Recent Profile Visitors

-

I love this beam hammer idea! im going to make it. ive figured out everything else, parts wise. but what do you call this offset shaft thingy thats highlighted yellow in the picture? Is it called an off set shaft? a U shaft thingy? my knowledge of machinery parts is rather limited to "doo-dad", "thingy", and the occasional "whatchamacallit!"

-

Looks awesome! just wish i could see how the internal mechanism works. This looks like something i am pondering to build, i just cant seem to figure out that internal circular motion action thingy.

-

What did you do in the shop today?

Dewnmoutain replied to Mark Ling's topic in Blacksmithing, General Discussion

Holy moly! These look amazing! -

What did you do in the shop today?

Dewnmoutain replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Dewnmoutain replied to Mark Ling's topic in Blacksmithing, General Discussion

How do those handles feel in the hand? Ive been making these russian roses. I have 1 month to make minimum 36, but the plan is to make 50. Im donating the roses to the local High School musical program. The plan is to raffle off a bouquet (12) roses each night, and the remainder to be sold individually. Music director loves the idea. -

What did you do in the shop today?

Dewnmoutain replied to Mark Ling's topic in Blacksmithing, General Discussion

i made (dramatic pause!) a sprinkler can! Finally got sick of using a plastic bottle and holding my arm over the flames -

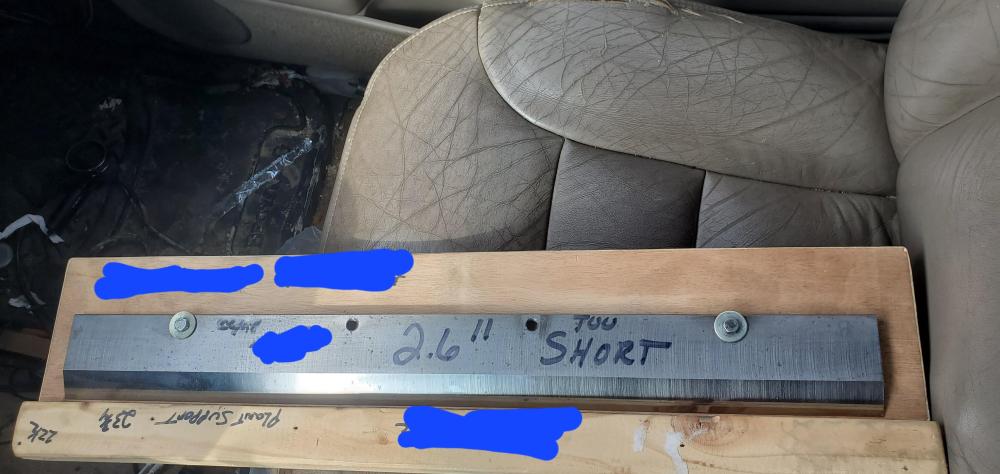

Visited a friend of mine a couple weeks back. And every time i do, he always gives me some scrap steel to play with. Some of its ok, like the metal brackets used to hold down the massive printers to the transport pallets that were delivered to the shop. Some of it is not, like the thin galvinized steel that came from somewhere.( I dont remember where he got it. ) But sometimes, he gives me some interesting steel. Before, it was a couple hundred feet of wire spools for stapling booklets that got tangled up in the printer. This time, he gave me really unique steel. 23"L x 4"H x 0.5"T 18% tungsten carbide steel. And he asks me "can you make me a knife out of this stuff for me, please?" Ummmmmmmmmmmmmmm.....hmmm....

-

End of march vacation to pigeon forge, Tennessee

Dewnmoutain replied to Dewnmoutain's topic in Everything Else

Thanks malleus, ill check those places out. -

What did you do in the shop today?

Dewnmoutain replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What is the fascination of knivemaking?

Dewnmoutain replied to DerFeldschmied's topic in Knife Making

i made those mistakes with the slits, drifts, punches, and chisels, and all my other forging endeavors. still got angry when i made a sparkler out of a strut coil, but i figured it was cheaper to learn that way than with expensive knife alloys. I didnt make an attempt at knife making until i had spent a year learning how to manage the fire, hammer control, and so on. -

Hi there. My family has a vacation scheduled to go to Pigeon Forge at the end of this month. And for the most part, i am looking forward to the trip. But, there is a day where the family is slated to go to Dollywood and spend a day there. That is the part that I am not looking forward to. Due to my PTSD, i just dont do large crowds. i go from withdrawn and angry, to really really angry and blacking out (usually when this happens i tend to make lots of people cry). So I was wondering if there were any blacksmiths in/around the greater pigeon forge area that would be willing to babysit a traveling blacksmith for a day? id be willing to swing a hammer and help you with that project that needs two smiths to work on. we can wax eloquence about the exact number of too many irons in the fire and if it is possible to strike when the iron is too hot. if youre so inclined, feel free to send me a PM. thanks

-

What is the fascination of knivemaking?

Dewnmoutain replied to DerFeldschmied's topic in Knife Making

honestly...i find knife making to be much much easier than the other types of forging. When you really look at it, your just taking a piece of steel, and hammering it to certain thickness with a certain width with a certain length. then you can grind it down to a set shape, throw an edge on it and youre done! Anything beyond that is a layers and layers of window dressing. Due to my PTSD, i have a heck of a time trying to figure out how to make punches, chisels, slits, drifts, and tongs. i somehow always manage to screw it up and in turn have my slit holes and punched holes come out all jacked up. Or make two left handed tongs that dont line up and i have to reheat it again and modify it to fit the other, and do a crap ton of filing to make it all line up properly (It's especially annoying when you come across that person who picks up a hammer and within 2 hours is able to make a working pair of tongs with 3 heats.) -

made an ollie hammer

Dewnmoutain replied to Dewnmoutain's topic in Power Hammers, Treadle Hammers, Olivers

well, i thought id resurrect this old post as it pertains directly to this hammer. because of injury, i now have the (forced) free time to contemplate and work on this hammer. so after a couple months of using this hammer, it was annoying me that no matter how hard id stomp my foot to get the hammer to impact the hot steel, it wasnt leaving much of a mark on the steel. my initial testing and uses were with pieces 1/4 to 3/8ths thick, so the hammer would do the job. But when i moved up above 1/2", especially 1" variety, the hammer wasnt hitting as "hard" as i thought it would. i monkied with the setup some more, and just couldnt, at first, figure out what was causing the softening. So, i just hung the thing up and said "meh, ill get to it later". That was back in January. Had a friend come over, and using my army tenacity and his nuclear engineering thinking, we figured out that the culprit is the springs itself. Turns out, they dont move until they have a 20+ lb load applied to them. So, they are too "weighty" (or resistant?). i scrounged through my scrap steel, and found some old springs, but they too, have a higher load limit in the 20+ lb range. so i thought id ask here, since i now have the free time to work on this, does anyone know where i can pick up some weak springs? ive already hit up the local hardware store, and the ones i picked up were also wound tight and would only extend half way out with a 20lb weight on them. i tried looking at some online websites that sell springs, but this is where my knowledge of choosing a spring is very lacking. anybody have experience with finding or buying the types of springs im talking about? -

to frosty: i had the same idea initially and looked at my household knives, but they were plastic handles molded on at the factory. So in my head, i discounted measuring them. to JHCC: curse of large hands huh? to george: I was thinking the same way, making the handle for what feels good in my hands. But lots of people are different, and what feels good for me doesnt for others, hence why i was asking if there was a generic thickness that one starts from and works from there, you know?

-

I know im overthinking this way way too much, but i have to ask this. 1st question: Ive read other posts on other sites that talk about 3/8", 1/2", 1/4" thicknesses of scales, but no one says if said thickness is for each individual scale, or total overal width including the steel? If i say "yup. I added 3/8ths scales" am i saying that the total width of the scales is 3/8ths, or am i saying that each scale is 3/8ths? 2nd question. Im currently working on a few knives, my first time making generic blades to sell to an unknown person. Ive made a couple blades for people i know, had them come to my shop and custom fit the handles to their liking. So im a bit unaware of what a generic overall scale handle thickness should be. Including thickness of steel, am i shooting for an overall width of 5/8th? 3/4s? Bigger? Smaller? Thanks for the help