-

Posts

167 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Stitch

-

-

Thanks for that reminder! As a toolmaker for years, I know all too well what can happen!

I made a lot of kindling when I was testing it out! Lol!

Nice tooling Hans!

-

Hey John,

Mac stopped in the shop yesterday and wanted to get some hammer time in. Here's the video.

Your turn!

-

Hi John,

If you have Galvanized or Zinc around... get rid of it!!! Lol! I use muriatic acid to remove plating.

It works fast but I believe they have the death penalty in your town if you bring it into the city limits! BTW, I located

the charger. My son "Borrowed it for a day" a month ago. Stop in pick it up and hit some steel!

-

I have an old manual charger you can have. I de-rusted a bunch of hit miss engine parts with it.

I bought another this summer at the flea market and this one is sitting around doing nothing useful.

Just stop in and pick it up!

-

I use YouTube. Just upload to your channel. Here is a YouTube video on how to.

Can't wait to see it!

-

Musky,

Will there be any videos of it running soon???

Looking forward to seeing it.

-

I just put up a video of my tire hammer running on my webpage. My buddy came over this morning and we forged Turkey lifting

forks for our wives.

-

3 hours ago, eseemann said:

Now that is purdy! I love it. Is there a spring inside the green buffer at the linkage? If you feel like posting a video of it in operation I would not mind seeing it.

Thank you! I have a short video of it running dry. I may make a video today. Yes, the green tube is just a safety cover

for the spring in case it breaks or comes loose. I haven't made the front guard plate for it as of yet. I found my spare tire on FleaBay for $25

-

-

My son has Scrimshawed some of the knives I've made for him and they came out like the original Ivory ones. I wish I had that talent.

I hear ya Gene. I prefer black paper Micarta as my favorite. Although canvas and linen have a better grip especially when sand blasted.

A countertop company gave me some 2x4 sheets of the white Corian a few years ago. I have enough left for my lifetime.

-

I have sheets of white 1/4" Corain. I'd be happy to send you some scales if you wouldn't mind paying for the postage.

I use a lot and it ages beautifully like Ivory except without the cracking.

If you would like some professional knife templates, I can have my wife send you some samples from her template business.

She was nice enough to give me a forging page on her website. Still uploading pictures.

I'm not sure if I can put the link here because it will also link to her business site and I don't want to get booted for spaming here! Lol..

Stitch

-

Gee! Thanks for the sarcasm Thomas! I wish I were as perfect as you!

"Most" Anyone would obviously omit the cast iron ones...

-

-

Now that is one really cool fire poker!

-

Lol! Now that would be a Franken-stand!

-

All great suggestions guys! I'm going to try them all Thank you!

-

Having an abundance of 1/4" H.R., I have been playing around in the shop making simple 2 piece Banana stands for the special ladies in my life. They love them but

I cannot seem to come up with a better way to attach the legs. I have been Mig welding them and I really dislike the ugly welds.

Anyone have any better suggestions? I am having a mental block figuring out this simple task. And I am no beginner. LoL!

Thanks guys.

-

Lots of great suggestions here! I've used most of them over the years. I now mostly heat my items to 200-250F and wipe them down with peanut oil. I then re heat to 200f or so.

I am not sure if it would not affect everyone with nut allergies or not but a buddy of uses his with no problem and he has nut allergies. If someone tells me that they do, I use Canola oil instead. Works great for heat treat too.

-

Hi Charles,

Yes. I have 3 diagonal die sets I use and more to come. This set is for my fuller attachments. I didn't make a video with them on yet.

More video to come.

I appreciate your input, Thank you Charles!

-

Hi Wayne,

Hey, I appreciate that! I am always open to suggestions and some of the fantastic creativity offered by the members here. Your creativity is top notch.

I have enjoyed reading many of your post's. You and a lot of the other members are very generous with your knowledge and experience and I truly appreciate it.

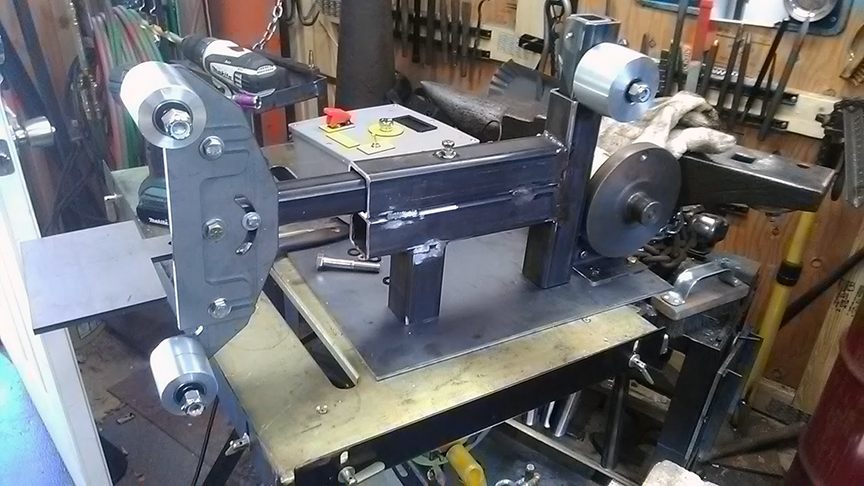

I have been to your site before. Your belt grinder design is truly amazing and the most intelligent design I've ever seen is the perfect knife maker machine tool system IMHO. Pure genius!

For years, I only free hand hollow ground my knives since that's how I learned to do it from a couple friends that were guild members back in the early 80's. I've since leaned more towards the jigs and guide method as it adds so much to making a high quality knife.

I plan on ordering your DVD and some components from you in the near future. Your belt grinder has been on my wish list for some time. (and your disk grinder!) It will be my late winter / early spring project for this year.

Thank you Wayne for stepping up the game!

-

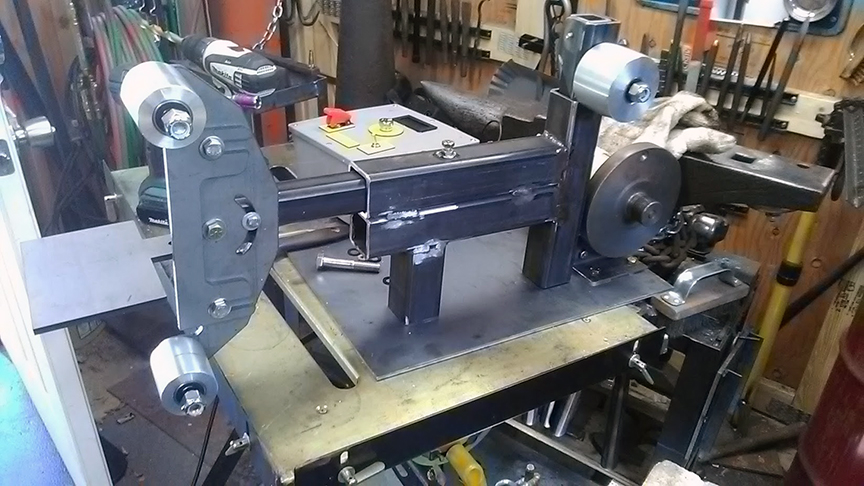

I'd already thought of that obvious possibility and I am adding a filtered shroud with forced air flow to protect the motor. I plan on a long life for this motor. I do like the idea of readably available motors and controls. Treadmills are very easy to get, just dust them off and there you go! I have a 2hp VFD that I am saving for my CNC mill project.

Even though I will only have a couple hundred dollars invested, I'm building this one for versatility and long life. I like the overall simplistic design. It just needed some tweaking to take it to a higher level for my needs. I saw one 2x72 built from wood, very clever and would work fine in a pinch or for someone with limited funds.

Thanks for your input.

-

Well,

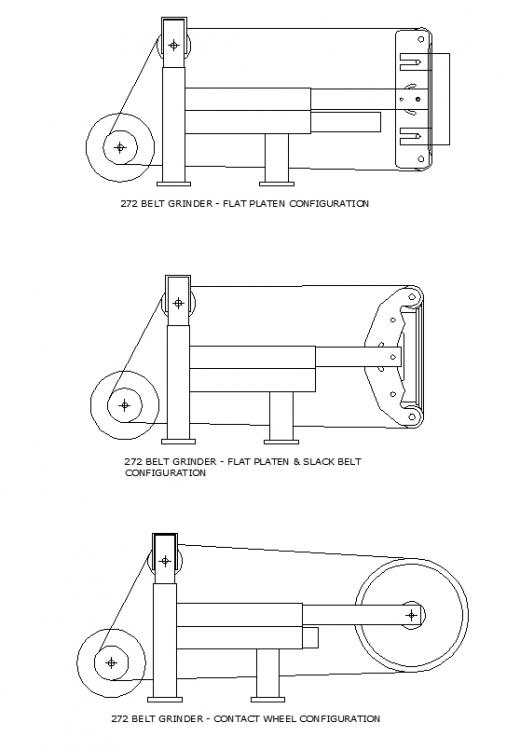

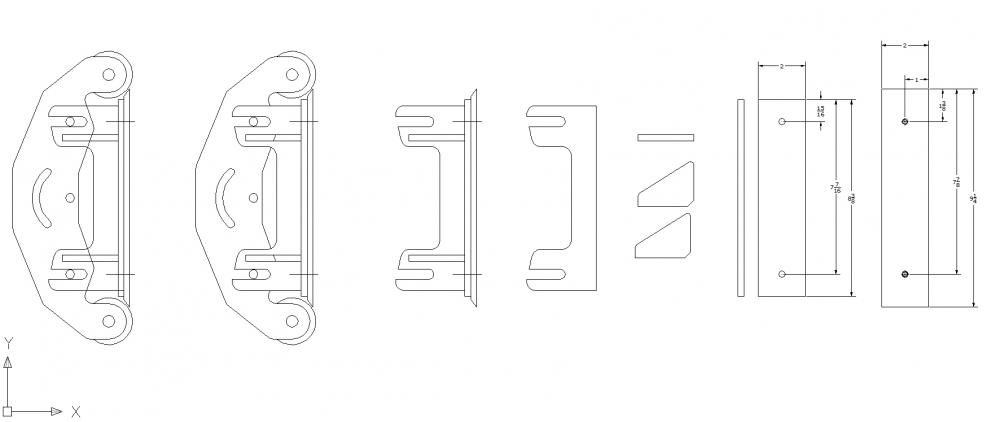

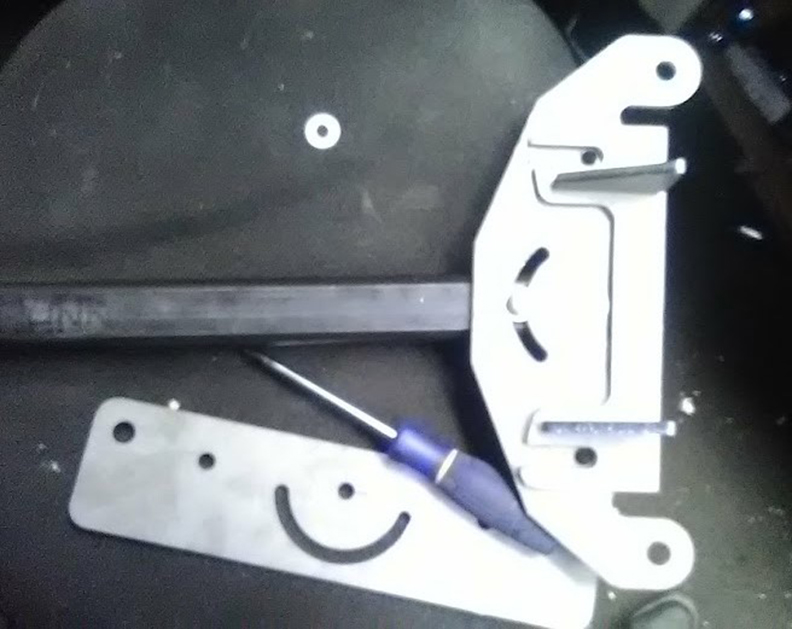

I finished my tire hammer so it's on to the next project. I decided that I wanted a belt grinder more versatile than

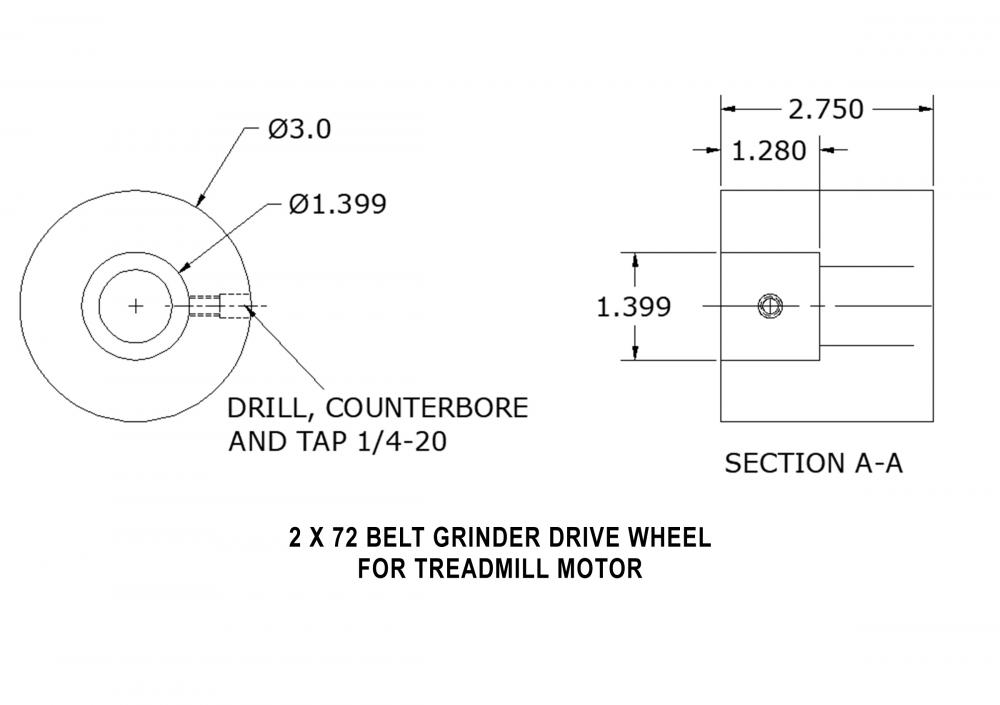

my old Grizzly 2x72. I started this project last Thursday. I am using a 2.25hp treadmill and mc-60 controller.

I CAD drew the platen and attachments and had a local fab shop laser cut them for me. I also had them cut a straight platen for upright work.

I bought the rollers from Oregon blade maker. Very nice quality. I plan on adding a ten inch contact wheel and arm.I should have everything finished and running tomorrow.

Then to build some jigs for it......

-

Typing it as we speak! Lol...

-

Bolt tongs from bed frames

in Tongs

Posted

I am having all of my friends and relatives digging up their unused bed rails!!!

How cool! Thanks for sharing John!