GlennA

Members-

Posts

10 -

Joined

-

Last visited

Contact Methods

-

MSN

winder@msn.com

Profile Information

-

Gender

Male

-

Location

Bethany, WV

Recent Profile Visitors

508 profile views

-

Das, Ah yes .... Charleroi ... just north of the "Broken Bridge". I was just by there a couple weeks ago .. on my way to Greensburg to pick up a Craigslist 400 Could I ask you to contact me when you get ready to go buy your coal ? I may just meet up with you & buy a ton for myself. Bituminous .... Right ? Thanks !

-

Oh yes ... I will weld a "Sticker" or three to the pipe. Thanks !

-

JHCC, I built an anthracite fire a couple of weeks ago ... & quickly found out that I needed a deeper fire to even get a Sweet Spot. This anthracite works nothing like the bituminous that I have fiddled with in a friend's forge a few years ago. My anthracite fire did not study the Fire Cross Section Diagram. Stoopid Coal ! 8^) Thanks for the advice tho !

-

Glenn, 20 years ago, I worked a "Pittsburgh seam" here in Brooke county.Wv & worked a "Waynesburg seam" in Eightyfour, PA I can't find a single source of Bituminous in Wheeling (about 20 minutes south of me) ... I would LOVE that ! Tunnel Ridge in Short Creek is only about 10 minutes southwest of me .... I've been thinking about stopping by & asking some questions. I know they belt all their coal to a river barge loading facility on the Ohio River. Wanna hear some irony ? .. I'm currently working right next doot to the former Wheeling-Pittsburgh Coke Plant in Follansbee, WV ... now known as Mountain State Carbon. They have MOUNTAINS of Coal & Coke piled up. Yeh ... I used to work in there too. Sheesh ... I could have had buckets of the stuff & no one would have said "Boo". Daswulf, I have a couple more "leads" to pursue locally ... but I may end up needing your assistance. Thanks ! I'm not chasing coal very hard right now ... just getting things taken care of before I need it ... getting things ready around here for winter ... & nursing a bad back. Thanks guys .. for the info & replies ! I like those ideas Lou ! I am currently gathering up steel to make a new table for the forge .... I may incorporate the side blow into the design. This may help when I convince one of the local Coke hauler trucks that his tailgate latches need adjusted & I will do it along side the road ... for free. I had actually thought of scabbing something over the 400 intake to tap into with a hair drier or such. I've got several circular magnets that may work like a peach ! This would also insure that the positive air would not be lost out through the idle 400. Thanks for the reply Lou !

-

My plan is a Deep ducknest to keep this dang anthracite burning. That's why I have the clay so thick. There's actually two layers of 1.25" fire brick under the clay. I'm not sure the clay is gonna stick to the edges of the ducknest / bricks ... as it's a pretty thin coating & it already feels loose. I'm already gathering steel to make a new square table ( .250 ) & .500" thick ducknest out of T-1 . This will allow me to use two layers of brick @ 2.5" thick ... & NO clay. Hopefully .... soon .... I'll be able to find a source for bituminous .. here in the "Land of Bituminous Coal" WEST VIRGINIA !! 20 Years ago .. I could pick up a sack of bituminous along the roads that fell off the trucks ... but no more.

-

Thanks for the reply & the flowers Kevin ! I have a piece of 7" diameter thick wall pipe. I plan on welding a 3/4" thick x 18" x 24" plate /table to the top & a gusseted leg hole plate at the bottom ... then concreting 2' of it in the ground. I think this will give me plenty of access around the vise ... & I don't think it will move. This vise is 33" from under the top mount to the bottom of the leg ball. I also have two thick Street Grates that I plan on making a table out of .... any thoughts on how high I should make it ? Anvil Height .. or Bench height ?

-

-

A very good friend of mine delivered this to me last Saturday. I had told him a few weeks ago that I was starting to dabble in Blacksmithing. The only thing I can see that is hurt ... is maybe the movable side is bent just a little .. right below the screw hole. I will straighten it later if I feel it is needed. I got the 400 blower back together & running smoothly .... got the 401 sheet metal pan all clayed up & a 3" deep "ducknest made for this darned anthracite coal. (only coal I can find locally) ... (yeh ... I'm in West Virginia .. northern panhandle town of Bethany .. for the curmudgeons) The State famous for bituminous coal ! 134 lb Haybudden is rr spiked down to the stump. .... I'm almost ready to beat steel !

-

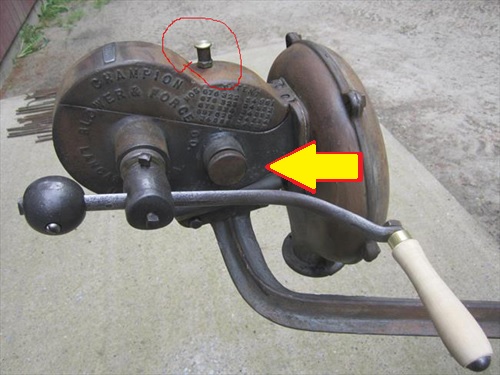

I need a grease cap for the sides / ends of the shaft the bronze gear is on. (Champion 400) The caps for the input / crank shaft is too big. I could also use a new fan ( my blades are badly rusted away). I'm going to try & repair the blades (sheet metal blades) with JB Weld ... any thoughts on this ? Will it work ... or fly apart & kill my dog ? Anyone ever try to reproduce the tin blades & re-rivet them to the cast center spokes ? Thank for any replies ! Hillbilly Newbie here ~Glenn