-

Posts

1,804 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Judson Yaggy

-

-

Cut dovetails into it to wedge in harder dies, a la cutler's anvils.

-

Just to start a hand made leather belt should provide adequate service, save your money for when you know everyting else works and then upgrade the belt to something modern. As for motor HP please weigh the head/hammer/tup, note the pulley diameters, and let us all know those numbers and we can roughly estimate motor HP and RPM.

-

Steve (above) is still around but posts here infrequently. Still has a Bull. Try PM to get a hold of him. I can get you his contact info if he doesn't respond to pm. Bull turned into Phoenix Hammers, they are still around if you google, perhaps they will feel like talking.

-

I would be shocked if a scrap yard didn't have a set of torches handy, and would also be shocked if the yard workers couldn't be bribed to make a cut for you with a box of doughnuts.

But personally I'd keep it like it is and stand it up on end.

-

Glad you are ok friend. Stay safe.

-

Dies for that machine (or most antique mechanicals) have not been made for 50 or 100 years or more, depending on manufacturer. Little Giants are the exception, there are JUST enough left around to justify modern production of their dies (dies for LG's will cost more than $500 USD). Your machine is not a common one, you are looking for a needle in a haystack if replacement dies exist at all. Make good drawings and pay a local to you machine shop to cut new ones.

-

There was also a design in the old Blacksmith's Journal from 15 years back or so. Smaller cylinder mounted vertically between the legs and used some sort of 4 bar linkage.

-

I'm a little underwhelmed with the control of that Beaudry above. It travels on another blow or 2 and it doesn't seem to be able to stop at the top of the stroke. When punching the hole he has to quickly pull the work out to avoid another hit rather than having the ram stop when wanted.

The VFD might be great for starting and running the hammer, but I firmly believe all mechanicals need a brake to get optimal performance. The Beaudrys I've run had well tuned factory brakes and could start and stop on a dime. Even halfway thru a downstroke.

-

4 minutes ago, JHCC said:

The Undisputed King of Anvils

Always good for a laugh!

OP, that's a good anvil. Happy hammering.

-

20 hours ago, anvil said:

I have never seen any "factory" recommended mounting system for power hammers

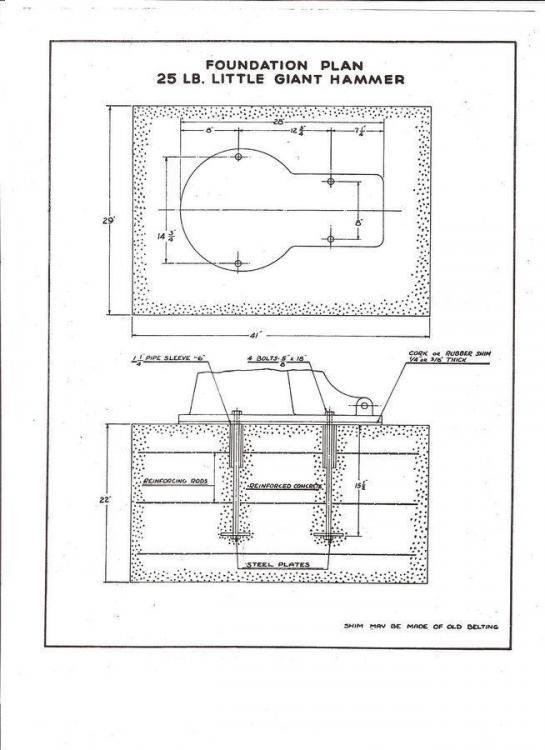

Perhaps not for direct contact between cast iron power hammer bases and concrete inertia blocks, but there is a fair amount of documented literature that uses concrete as the primary mass under power hammer bases. Often combined with oak boards/timbers and in the modern era Fabrika pads, but a concrete foundaition block is fairly standard for backing up a power hammer. Even little old Little Giants had factory literature showing size and bolt placement of the concrete block they recommended under the hammer. http://www.newenglandblacksmiths.org/little-giant/

-

Peter Wright. In the 100# range.

-

8 hours ago, AR. Hillbilly said:

I would never assume anything about the guy without learning a little about his experience. Then I would try to give some positive advice.

Well said.

Tire hammers if built to Clay's design are just fine. If you have experience and want to step up to the next level, they are a great place to start. Fair warning, there is a serious rabbit hole you can fall down when it comes to power hammers! (grin)

-

On 10/24/2018 at 4:03 PM, Kozzy said:

In a more "art shop" situation, would such a hammer still give reasonable service if one were to use something like half the HP, changing the motor pulley so that the blows per minute were also halved? In this case, that'd effectively mean changing to 5 hp (ignoring other machine energy losses for the question) which is more reasonable for a single-phase shop.

Slower rotation of the input changes the reaction of the springs and linkage. Slower rpm would degrade the performance of an antique mechanical. It's a dynamic system. And even an "art shop" needs to put product out the door to pay the bills, so running a hammer the way it was designed is advantageous. Mechanicals do tend to run faster than air hammers, but the bigger ones run slower than small ones typically. Thanks to SS for the link to the NEB website, you can find a bunch of info on antique hammer rpm there. Note that older motors had a little more copper in them so they were a little more robust when working on the bitter edge.

-

Love Beaudrys but yeah, no love on the vid.

-

Open up the space between the dies.

Can you adjust the location of the eccentric?

-

I've seen this hammer in person, and encouraged Bryan to buy it for a very reasonable price.

The wedge(s) on the back of the lower die are 2 pieces, driven into the dovetail opposing one another. Look again at the pics above. Bad practice and that's a little troublesome , but the portapower, drilling it out, and comealongs (in order of precedence in my opinion) should work.

-

33 minutes ago, GrumpyBiker said:

Has anyone attempted one ?

I've actually made a bunch of these, and mild steel (what we call a-36 these days) works just fine. Didn't bother to google it, sorry.

-

That's a Howe, patented as a St.Laurence hammer. Made in Rutland, Vermont. Quite rare, supposedly seriously solid industrial machines. 3 phase wouldn't stop me, easy enough to swap the motor or put on a phase converter.

-

Chile Forge.

-

This is awesome, keep it coming!

-

Several possible causes in no particular order. To be more accurate we need to see pics (close ups) of the machine and its particular parts and the resulting work piece.

1. Ram (tup) guides too loose allowing the dies to shuck sideways upon impact. Even a little slop will start to affect the WP.

2. Dies not perfectly parallel. Could be in the machining of the dies, could be in the fit-up of the whole machine.

3. Operator error. Not rotating perfectly 90 deg. per turn or holding the stock out of level with the dies. Film yourself working with your phone, it'll be an eye opener.

4. Aysmetrically heated work.

We need more info.

-

I had a Hill (200#) for a few years. Good solid anvil, slightly oddball hardy hole size.

-

I'll poke around the scrap pile. Think I may have something close.

-

Jennifer, how big a piece of wrought do you need? I have some big chunks, could bring them to the meet next weekend...

Shop rebuild

in Building, Designing a Shop

Posted

I put a Ken's Kit on a 135# air hammer about a year ago. Absolutely amazing once you get used to the action! Pretty thrifty on air consumption as well.