-

Posts

253 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Pancho07

-

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

Thanks PVF, I'll have to try that. -

Looks like something I would hang in my house save that I would have countersunk the hold to allow for flat head screws but that's just my preference.

-

That's the bunny. ill put up some actual pictures on Monday, that was actually from a friends fathers grave but it was the only picture I could find without knowing the name. The teeth were riveted into the rings and hub. If they are no good then I'm out $12 so I'm not too worried and I can always throw them in our scrap pile and get my money back when we take a load of rolled barb wire up. I had thought that the tips may have just been hard surfaced and I don't know if anything can be done with that or if it will heat unevenly and just crack/shatter when I try to do anything with it.

-

Had to go get some parts the other day and was able to stop by the scrap yard, picked 3 of these up. For the life of me I can't remember what they are called but I know that they came off of a plow. I've got 2 questions about them: 1. Are the teeth good enough steel to make punches or other tools out of? 2. This is probably a duh question but would welding 2 or 3 together for added mass or a longer tool be worth doing or would that be creating a fracture point? I'm leaning towards the secondly but figured it couldn't hurt to ask .

-

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

All was going great until I quit paying attention and burned the loop off, guess it goes into the reminder box -

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

Will do John, if all goes well with the process I have in mind should be done later today. -

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

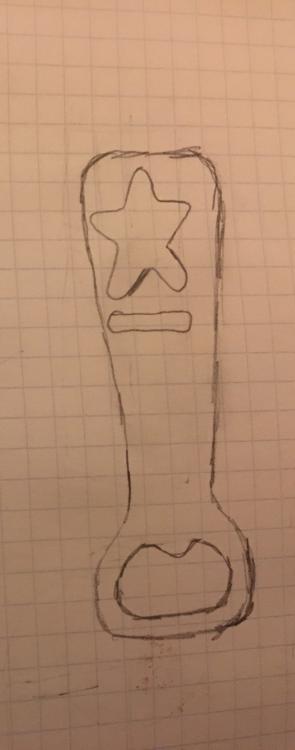

After sleeping on it some more I think I'll probably go with something like this. ill probably try the other as well just to see if I can but I would imagine this would be more comfortable at the least. -

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

Thanks for all the ideas John B: I'll probably only be doing the one but it's going to someone with a large family so who knows. For any other project a twisted handle/shooting star would be good but as this is their family brand I don't want to take too many liberties with it. Kozzy: I have a plasma cutter so that's a possibility if I can't figure out another way. There aren't too many astronomers out this way though. Bigconductor: may have been some miscommunication, the star wil be on the handle end not opener end -

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

So I was asked to make some brand bottle openers for Christmas, luckily they asked for them in plenty of time. One of them should be pretty easy, the other is a bit of a head scratcher for me. I've got a couple ideas ranging from extremely easy to probably easy for the curmudgeons here. Whichever what I go I know that I want the inside of the star to but open so it can be hung on the wall. First thought is to just chisel it out, which of course would work but doesn't really stretch me much. Second is to basically make a star form and start by drifting it round then using the star to collapse the inner points back in. The second sounds easy enough but I'm not sure how to go about a star form or if it's even worth trying and if I don't need to make more than one or two. -

After thinking about it these would have actually been used on saddles and not shoes

-

Been working on cleaning out outbuildings at the new place and found some cobblers hammers, know they aren't for forging but thought somebody might think they were kind of neat. Not sure whether one was refaced poorly, used improperly or made millions of shoes but seems alittle more worn than I would think pounding nails into leather would account for.

-

Very nice

-

Wrought iron style headboard

Pancho07 replied to Eisenreich's topic in Blacksmithing, General Discussion

Following, trying to convince SWMBO to let me make something similar -

Tennis Elbow taught me proper hammer technique

Pancho07 replied to intrex's topic in Blacksmithing, General Discussion

I had a similar problem a few weeks ago as well. My arm is recovering and I didn't let myself get too bad. I probably shouldn't have but I "played through the pain" and was able to figure out where it hurts and where it doesn't, proper technique is a very good thing. -

I had thought of that and I've actually been using it for a couple days, and haven't had a problem working both sides of the fire yet, if it becomes an issue won't be tough to change angles.

-

Made this the other day, it's not as smooth or clean as I'd like but it works well so I won't complain too much. Not too pleased with the handle but it doesn't feel too bad, thinking about tweaking it but I may leave it for something to look back on

-

Show me your Bottle Openers!

Pancho07 replied to Arbalist's topic in Blacksmithing, General Discussion

Very nice jozi -

Lately I have been using the coal forge more than the larger propane forge and the last couple days no matter what I try I can't get the fire to light. Haven't been doing anything different it just won't light. Don't have any orders or anything so I'm not missing out on any inportant work just practice but just getting really annoyed. What does everyone else do when the fire doesn't cooperate?

-

Ray I was about to ask who your friend was as we used to be really big into the dog trials and hadn't heard of anyone getting hurt, then I saw where you were from. That brand looks pretty nice. Ausfire, when I rebuilt our irons out of stainless I didn't have to put any bends in and they took forever, think i will borrow a trip hammer next time they need doing.

-

Hehehe close

-

That's how I've done the others. If I didn't say before the rest of the irons that we use were made from stainless, and I have some on hand but if i don't need to use it then I wont.

-

Just the regulator on the propane bottle. I will probably go ahead and use mild, it's reasonably inexpensive at the moment and if it doesn't last very long I won't be out much but it will be good practice for other things.

-

Also tanners prefer a smaller brand or none at all as they usually have to cut that out.

-

The cowling brand is not overly large but we brand when they are small so the brand will grow with the the calf, smaller initial brand means less trauma to the month or weeks old calf. Whether or not a calf brand is needed we've always used one so I'll be making one. Would propane vs wood fire make a difference? We use a zerk with the internals removed as our orifice, don't know if that would change it or not.