-

Posts

159 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Thief_Of_Navarre

-

-

I believe the Birmingham pattern was intended for heavy shoeing and agricultural use thus no need for a step. There is also a Portsmouth pattern which has a squared off bick the other side to the conical horn much like a French anvil. I have no idea about the use for the Portsmouth pattern; shipping/rigging uses maybe?

-

13 hours ago, JHCC said:

Welcome aboard! Glad to have you here.

Nothing to add to what was said above (which is all good advice), except one little detail: you'll see a lot said here on IFI about "London pattern" anvils. What you have there is the somewhat less common "Birmingham pattern", which is distinguished by the absence of a flat step between the horn and the face.

I was about to chime in with this when I noticed you'd beat me to it.

Anvil looks in great condition. Is there any chance of a gander at the vice?

-

Yeah well the fact that they sell and you never need buy a birthday/Christmas present again is a minor point compared to the satisfaction of making them right.... :s

-

I've actually never heard of one. Must be an american Thang!

-

There's a workable bit by the heel. More than enough space for someone with your talents! But I concur, a lot of money for a poorly anvil.

-

I like pretties that double as practical trinkets. Keyring bottle openers, sporks, green woodworking's tools e.t.c.

-

Thought it looked like a fisher

Good score!

Good score!

-

Go and see it ASAP, do the rebound test. Depending on it the size a decent PW should have 80%+ . It might have just seen alot of bad treatment but be otherwise okay.

-

Looks a lot like a fisher. Never seen one unmarked though so I wouldn't put money on it

brooks/baker/Vaughn also made this pattern and many were unmarked.

brooks/baker/Vaughn also made this pattern and many were unmarked.

-

That's interesting, might have to play later.

-

Small Vulcan anvils do tend to look like this. I'm not sure why they look so obvious when they are smaller, it might be that they use the same thickness on the tiddlers as they do on full size forging anvils. From what I remember they are cast iron bases rather than wrought so they tend to be very quiet; easily mistaken for ASOs. The one I own had been damaged in a fire so for all intents It's an anchor.

-

I think I'm a bit out of touch then when it comes to retail prices SReynolds

Rboughton3rd, if you know any (fairly) local warehouses or builders merchants it's always worth asking if they have any spare steel from reach or counterbalance trucks. My day job is in a warehouse and they literally throw out high-reach truck wheels when the rubber is spent; they make great forges or cut into pieces they make jig sets for punching or bending.

The fork time is harder to come by as its usually sent off for repair, but it makes for a cracking starter anvil

-

A hadfield & Sanderson if I'm not mistaken (I was born half a mile up the road from that!). A shame!

-

Very nice, I like the simple black scales. Good job, I'd happily trade my dovo in for that

-

Cool video, I can see why you would want one now

-

Having read literature from Stonehenge and Avebury (I'm a local) I doubt very much their current erection is anything like what it was when it was supposed to have been raised. They dug most of it out of the turf in the Victorian period.

-

Wish I could get my brooks that quiet. Perhaps I need rubber aswel as the steel base, magnets & chain lol.

-

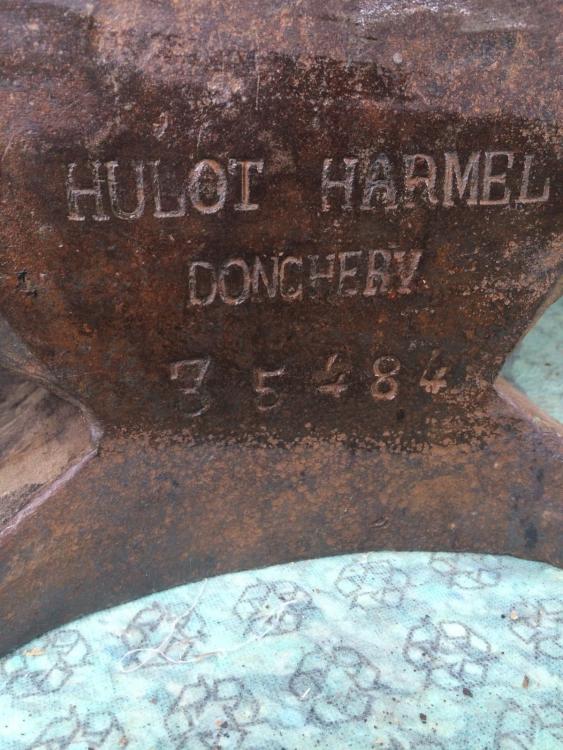

I payed £1.50 a Pound for it which was perhaps a little steep but I'm content. The guy who I got it from goes over to France with his brother and picks interesting oddments while he is there to bring back. He knew a lot about the sedan / donchery region that it's from but little about the anvil. French wikipedia tells me little other than when they started manufacture.

I just can't resist shiny pretties!

As for training with anvils you probably wouldn't want all extra load on your seisamoid bones, or if you are going for it you need one back and front to balance you out...

-

-

17 minutes ago, G-ManBart said:

I'm not even good enough to call myself a novice, so I'm planning to use my beat up 150lb Fisher for a little while, work on hammering technique, and then make the switch. I probably put the cart ahead of the horse, but had an opportunity to get the Refflinghaus immediately and didn't want to pass on it and then have to wait down the road.

Good plan. Remember to document your work, we love pictures!

-

I have a 1CWT PW. A fine anvil with only a tiny flat spot right near the middle (grrrr). Yours looks in great condition!

-

Looks like a Sheffield London pattern (probably late worker from mousehole as JHCC suggested.) The divot in the base is an odd one though.. I've seen a Sanderson like this but I suspected at the time it had been cut to mount on something.

-

Like has probably been said already (there is alot of good opinions here). For an anvil; it only has to be harder than the stuff your working and the hammer your hitting it with; Railtrack is perfect since it generally work hardens. Forklift tine is another good thing to have about (luckily I work in a warehouse so it's plentiful). Hammers look fine and the brake drum is fine imo; you can draw enough air through a bunch of bricks to make a forge.

-

Hard to tell brand without better images but I concur with everyone else that it does look like a PW by the feet. If it's anything like mine the rest of it still has some promise; Like someone said before ask less for it.

For reference I paid £150 for my 141lb c1918 PW in 'almost' perfect condition bar a very small flat spot where the previous smith has overused a point with hot stock and ruined the temper. I don't know how US anvil prices compare really, I imagine you pay more for them despite more of them being available in the states.

.thumb.jpg.a58a71089150255938045234e7ca9664.jpg)

Large Saw Makers or Sawyers Anvil

in Anvils, Swage Blocks, and Mandrels

Posted

That would be an excellent price here in the UK but I'm sure it's not quite that linear.