-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Forging Carver

-

-

That's a pretty nice anvil for a fisher. I got a 100 pound fisher which is great, but the hardy hole and edges are a bit messed up. You guys oil your anvils? How often and what kind oil? I might have to go an wire wheel my anvil and then put some oil on it. Anyways, arts a pretty good find and I have been on the look out for a heavier fisher for the future. It will serve you well!

-

On December 29, 2015 at 0:47 AM, Ethan the blacksmith said:

Well, I must be fancy, mine is made from half of a old wooden wine barrel. It works really well, and holds lots of water.

Yeah I've seen that thing in your videos and it is huge! You had a great idea on that one!

-

Hi,

So I have been reading some smithing books and watching some videos and was watching and reading about how the smiths say to hold the hammer. By hold I mean wear on the handle. Many guys say you should hold the handle at the very bottom. However, I was watching some videos by Brian Brazeal and Alec Steele and they seem to hold the hammer above 1/2. Which is the correct way? I know that the lower you go, the more mass a piece receives from the hammer but he harder to swing. Vise versa for going higher. My question is which is e right way so that I possibly don't make or stop any bad habits. Thanks

-

I would imagine that if there is only that hole for a prichel hole and no hardy hole, it probobly isn't a striking anvil. Why would a striking anvil have a prichel hole and no hardy hole? Usually it is the other way around. I am no expert though.

-

All you really need for a striking anvil is a piece of steel that you aren't afraid to beat up. The reason you have a striking anvil is so you don't damage your anvil, and striking anvils are a bit lower too. Whatever that is, striking anvil or not, it seems like it would work. There's that nice wide spot in the center which will probobly come in handy. I can't see fto me the photos and I am no expert, but the only issue might be that it's too thin. Don't quote me on any of this, becuase I am looking for a striking anvil or going to make one myself so I don't have any experience with them. But if it's a good price, then I would say get it.

-

Ok thank you yyf

-

13 hours ago, yesteryearforge said:

Thanks Bigfootnampa

The candle cup is a separate piece

How do you attach the two pieces together? Solder?

-

9 hours ago, ThomasPowers said:

When I lived in a city fall was the time when people would junk their grills rather than store them in their limited garage space over the winter. In the ritzy neighborhoods you could even find brand new propane tanks out at the curb!

Thank you. It is hilarious how you used the word ritzy. My mom and dad were playing scrabble just now and my dad made the word ritzy, and my mom didn't believe it was a word. I got to show them this for evidence!

-

10 hours ago, JHCC said:

I won't presume to dictate to the professional, full-time, or more experienced smiths in our midst, but my own approach to this is also "The best way is whatever works best", with the addendum "to achieve the desired effect". The desired effect may be a particular surface finish (be it rough fire scale, deliberately exaggerated hammer marks, subtle undulations of a flatter-smoothed surface, or ground mathematically flat with a high polish), a specific practical use or purpose, a degree of structural strength, speed of production, the cachet of being "hand-made", and so on. All of these are mediated by the skill level of the smith, the desires of the client/end user, and the tools and materials available.

In my own case, as an "evenings-and-weekends" hobby blacksmith who doesn't have to make a living from my craft, I tend to lean towards doing things by hand, partly because the practice improves my skill level, partly because I don't have a whole lot of power tooling (although I'm learning to love the angle grinder!), and partly because I love the aesthetics of a hand-finished piece. (Also, I don't know how to arc or gas weld.) For a professional smith, drawing out a railroad spike into 1/4" square is a waste of time; for me, it's developing my hammer technique and arm strength (and uses material I have at hand). It sure as hell does NOT mean that I think I'm better than anyone else because I'm somehow free from the taint of the Industrial Revolution or the sinful corruption of handheld electrics. It just means that I'm too busy to get over to the steel yard, too cheap to buy new stock, and not particularly concerned with the time spent drawing out that could be used for other (smithing and non-smithing) purposes.I totally agree!

-

Why do you have to be so good!!! Great work!

-

Alright thank you. I was going to use 20 pound propane bottles, but now that you say most don't put enough out, I might just go with the 40 pound bottles instead. Thanks again.

-

Now it is official too cold and snowy to forge. It is supposed to snow again this weekend. It looks like I am going to be done forging until spring. Time to stock up on some tools

-

Yeah I am going to get me a pair of uvexs. I think I am going to go with shade 2 rather than 3.

Even though you have been advised to use at least number 3, you are once again ignoring those that know. 2 isnt enough

-

8 hours ago, DSW said:

I have a great many cordless power tools that I use almost every day to make a living, but a cordless grinder isn't one of them. That said I have at least 8 4 1/2" grinders, 2 7" grinders and 2 die grinders. The only reason I don't have a 5-6" grinder yet is the easy availability of disks in my area. There's always at least 2 4 1/2" grinders and a 7" grinder on the work truck at any time along with a decent selection of wheels/disks.

Oh yeah I know. I was only joking becuase that way I wouldn't cut through the the cord. With grinders, you could do like 3 cuts then need to recharge. You teach welding at the school I believe correct?

-

The way is see it is that smiths in the past evolved and took advantage of the modern smithing technology of that time. They weren't concerned about being "old school", which isn't a bad thing by all means. Their whole purpose was to forge in the most efficient, fastest way possible. However, sometimes the "old" tools are easier than the modern tools. Cutting a small piece of stock could be quicker with a hacksaw than needing to get out the angle grinder and plug it in. Using a file to dress a small piece can be much better than a grinder or Dremel which could take away too much too fast. If you want to be old school with no power tools, then good for you. There aren't any rules saying you can't enjoy yourself that way. What I am trying to say is don't worry about trying to stay in one time period. Each period brought great technology and tools, so why not use the best of them to get the job done.

-

Yeah my next angle grinder should be wireless.

-

Alright thank you for the help. i think I am going to find myself a freon tank at the recycling center tommorow or some time this week. Thanks for the help.

-

This has me thinking. I always have water with me by the forge. I have to be careful not to get any dust where my mouth goes.

-

Oh yeah I would never forge that windy or cold. What I meant was when it is a gentle snow shower and not too cold. I'm not that crazy!

-

Well we finally have some snow here in NJ! Not too much, only about a 1/4". I have been wanting to forge with snow for the longest time. Most guys hate forging in the cold, but I love it! I wear short sleeves and get nice and toasty from the forge. It also makes you work harder to make more body heat!

-

I am not sure if I ever posted the finished horse, but I guess I will post it here. This thing was a pain in the neck. All those little fine hairs are from going over the entire horse with a woodburner for three months. It was totally worth it though. And of course they are upside down.

Lol I jinksed it again! Maybe next time I will say I am going to loose the powerball lotto!

-

I saw those, but they were from wrought iron which can be pretty difficult to forge with. Personally, I think you make some fantastic openers too!

-

-

Thank you so much. So my forge supplies are going to cost me about $50, good pair of ir glasses about $15, then the burner, hosing, and other supplies will prob only bring me up to $100 total for the forge. I suppose this isn't a bad price, after all your forge makes you your money.

Alec Steele Rounding Hammer

in Hand Hammers

Posted

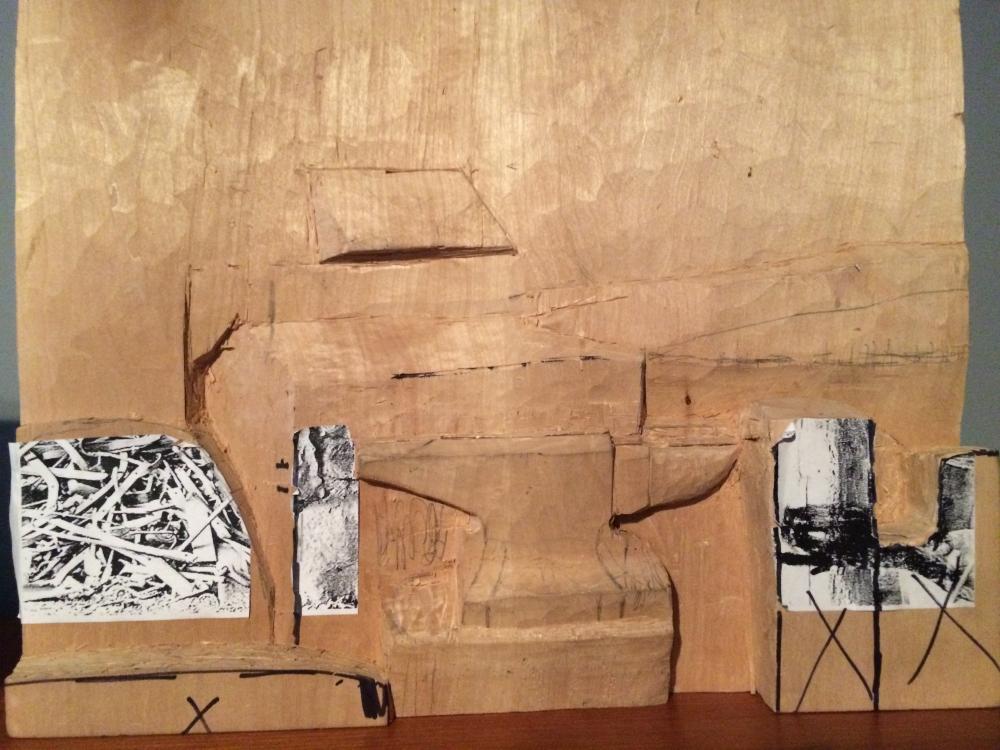

I just got this hammer a few weeks ago, right after I cleaned up for he winter. I am pretty excited to use it in the spring. It was hand forged by Alec Steele with a striker. I have been wanting to buy a rounding hammer for a while since it is a very versatile tool. You can move the steel quick with the rounding dye, and if held properly you have many different sized fullers. The way you control this hammer can easily turn it into a cross peen, straight peen, or diognal peen. The charred handle basically makes the handle much smoother, so you don't have to worry about sanding with fine grits. Also, you don't get those little black spots like you do on a regular handle since it is already black. It also makes you not afraid to get the handle dirty. The shape of the handle is very convienant becuase the oval shape makes it very easy to switch quickly to the different dyes of the hammer. It is balanced very well and feels lighter than it actually is. I know I'm going to get some argument on that one! Overall, it is a very nice built hammer hammer and I am sure it performs just as well!