-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Forging Carver

-

-

made this one with a spike exactly that size

wow that is a really nice blade! Thanks for the help

Those are probably about average. I've seen longer and thinner spikes and some thicker... depends on the RR and the tracks laid.

ok thanks

The lighting in your pics is such I can't read the thickness. Line spikes were typically around 5/8" thick I've seen different versions but I don't believe they were used on the line. Their length was sometimes fairly long probably for spiking through thicker lays of plates, pads or who knows what.

Frosty The Lucky.

sorry I stink at taking pictures, yeah they are 5/8 inch. Thanks for the help

-

-

Hi,

I am looking into making or buying a gas forge mainly for knives. About how much does the fuel cost to run the forge on a regular day of forging? I heard coal forges are cheaper to run.

Thanks

-

I can't remember off hand, and I'm away from home just now. I think 3" is about right for my one too.

Remember you only need a surface area larger than the face of your hammer.

Andy

That's a good point. Thanks

-

It's my belief that anything around the 100lb mark is perfectly adequate for 99% of the forging that most folks do. I forget who said it but one book / smith suggested everyone could get by on a 150lb anvil. - you don't need a monster anvil at all.

I have a similar Fisher (rarer than rocking horse poop in the UK) that is also 100lb and it is a fine anvil. I wouldn't take a sledge hammer to it but it will be fine with a general hand hammer. (I had to ask the same question not that long ago tbh)

Andy

Alright thanks. How wide is yours? Mine is about 3 inches and I'm not sure if it's wide enough.

Thanks

-

More important what size hammers will you want to use on it? I have a special anvil for student sledge use---the heel's already been broken off of it. Most the stuff you mentioned can be done with reasonable sized hammers for that anvil; but the 3 pound hammer I would be wanting to use a sledge on that I would not advise for that anvil.

Alright thanks. I am going to use mainly a 2 - 2.5 pound hammer, maybe 3 pound. If I get some extra help then maybe a 4 pounder. Are these too heavy?

Thanks

Fishers are nice...and quiet! I like something a little bigger for making hammers (the few times I've messed with it), for everything else you mention, I would say it's light, but in the just fine zone. Mildly beat up, but I've forged on much worse. Yah, avoid the big hammers on that one.

I'm guessing from the change in pics that you bought it?

Yeah I bought for $200. On the horn there are marks over it that looks to be from a grinder (there's a picture). Will this affect the work? Also, do you think the edges are too chipped for tong making?

Thanks so much for the help

-

No it was my fault. I didn't realize he was trying to help me find the results. I was confused at navigating through the forums at first, but know I figured it out. Thanks for all the help,

-

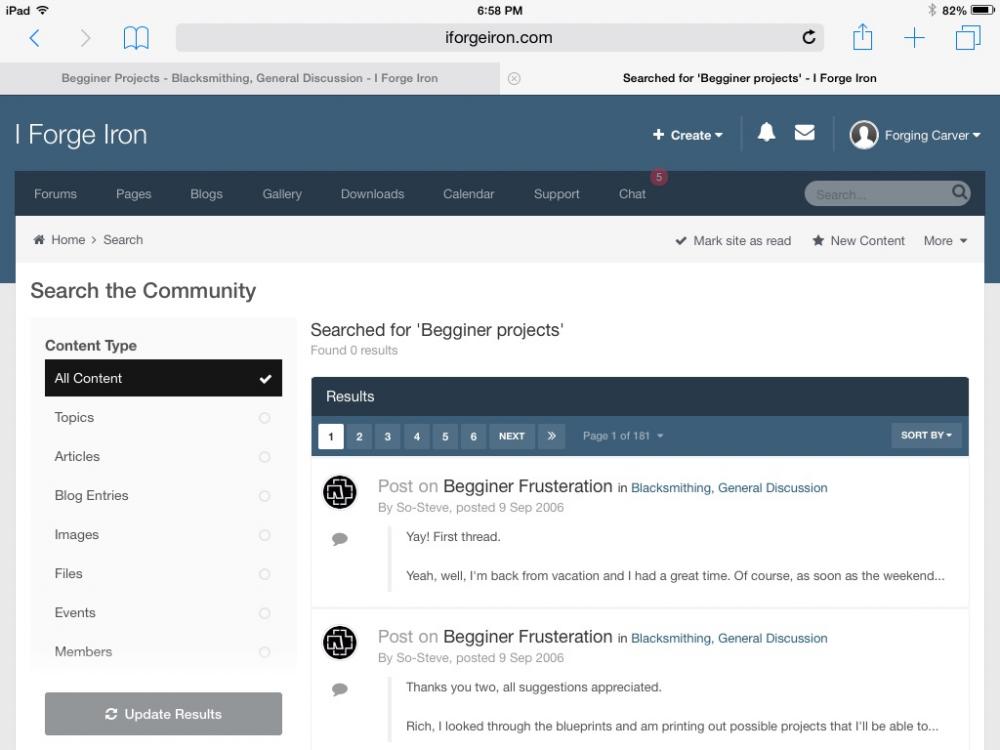

You're misspelling beginner.

Sorry I didn't realize what you meant.

Thanks

-

Oh I have been misspelling beginer. My fault.

Thanks so much guys

Most importantly, have fun and remember there is no such thing as a stupid question. If you feel uncomfortable asking the forum at large, just send me a private message and I'll do my best.

Andy

Thanks so much. Seems like I can always trust you.

Thanks

-

You're misspelling beginner.

We all make typos. Sorry did it affect the meaning, does it make it hard to answer the question?

-

-

Can anybody suggest a few begginer projects that will help me learn the basics, before I get into more complex things such as knives and carving tools.

Thanks

-

My main shop anvil is a 515# fisher. As a good quality "quiet" anvil they are especially good for smithing where noise is a concern. That looks to be on the small side so no heavy work. Not knowing what you plan to do makes it rather a Yes, No, Maybe situation. As a carver what would your feelings be if you told someone that a 1/4" mortising chisel looked good only to find they wanted a chisel for cleaning up joints in major sized oak for timber framing?

It is 99 pounds exact. What do you mean by heavy forging? I will probobly make knives, carving tools, hardware supplies (nails, hinges, etc), tools, and forging equipment (tongs, hardy tools, and hammers no more than 3 pounds. Is this too small for an anvil?

Thanks

Here are some more detailed photos:

-

I am new to blacksmithing and don't know what to use.

What oil you guys use to quench for hardening, as well as what you use for quenching while forging, such as for cooling the tip of a nail before passing it through the header so it doesn't get stuck or flattened?

Thanks so much

Your multiple question post has been split into multiple posts and placed on the correct forums.

-

I am new to blacksmithing and don't know what to use for material. I was going to use rebar and railroad spikes, but heard they don't work that well. I am looking into making knives, nails, and different types of tools. Is there any other scrap/not expensive metal I can use for forging these things?

Thanks so much

Your multiple question post has been split into multiple posts and placed on the correct forums.

-

Railroad Spikes

in Blacksmithing, General Discussion

Posted

Ok never worked with spikes before.

Thanks

Ok thanks, I paid 12 bucks for 10 including shipping