-

Posts

640 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Forging Carver

-

-

Nice stands! I got some good ideas for my next stand now p.

-

19 hours ago, ausfire said:

So how did you get on, FC? Did you fix it?

I have a bunch of 4" angle grinders because they are relatively cheap and I hate changing cutting discs, grinding wheels, wire brushes, buffers whatever.

If one stops running I go by the smell. An aroma of burnt plastic and sparks and white smoke and it's time to bin it and look for the next K-mart special.

Oh thanks for asking. Well I just cut off the wire where I cut it and then re-wired the outlet plug into the cut end and finished off with some electrical tape. The cord is a little bit shorter now, but I always use an extension cord anyways.

-

-

-

Thank you Frosty.

-

7 hours ago, notownkid said:

Yup esp when they keep coming from the same locations. We had a Tepee fire one night on the side of a hill and everyone turned out for that one just to see what was going on, even had other departments calling asking if we needed Mutual Aid. A neighbor called in a smoke seen coming from a barn one cold night, turned out to be steam from a large pile of Horse Manure behind the barn, 4 trucks, 30 men funnier now than it was then!

Yeah a lot of people are helpless. I mean it is good to be safe than sorry, but there's a line to that. My brother and dad go on calls becuase people set their alarms off becuase of shower steam or cooking steam. Things like that just waste the fire departments time, especially the volunteers.

-

That's really nice!

-

What I plan to do is wear clear safety glasses and have tinted glasses attached to one of those neck straps. This way when I am checking the color of my steel and what's going on in the forge, I can hold up the tinted glasses. When I am done and take my steel I can just let go of the tinted glasses and they will be safe on my neck.

Just tinted will ruin your eyes.

-

Yeah most of the calls are cruddy. Smell of a natural odor, steam from a shower, activated fire alarm. Most guys only respond when it is a reported structure fire.

-

10 hours ago, Ethan the blacksmith said:

Alec coats his handles in either canola oil or olive oil. Personally,I don't think it maters what kind of oil. Another advantage to charring a handle, it the water evaporates out, then you can replace the water with oil. That way your handles won't dry out, and the heads won't come lose. That's nice here in Alberta because in winter we have NO humidity, and my handles don't dry out because the swelling of the handle is upheld by oil not water. So if your handle soked in all the oil, in my experience, that's a good thing!

Yeah I asked Alec what I should do as far as maintance for my hammer and he said that you need to oil the entire thing with oil often. I was just curious becuase someone said that vege goes rancid and globby if you have excess, which actually I just looked at my hammer and you were completely right about the globby part and most likely about the rancid part. Thanks for the help.

-

19 minutes ago, Charlotte said:

Linseed oil for short term Idle on metal like shovel blades. LPS 3 ( a heavy nasty thick coating) for long term. 3 in 1 rag handy in reach to wipe any bright metal at the end of day. (saw blades, punches etc). Boiled linseed on wood any time. veg cooking oil is not really good on wood. Food items often get mineral oil from the drug store. Normal handles for daily use hammers get nothing as skin oil and handling takes care of it.

Alright so I will go find the linseed oil in my basement. Do you think at my one application of vege oil will affect my handle at all? Also, do you use the linseed oil on the head too? Thank you very much.

-

Alright maybe I will go with linseed oil than. Thanks

-

Yeah. If you want to be extra safe store the rags in a metal container that has a lid. I usually just throw mine in my quench bucket though.

-

That's pretty cool. It's a whole lot nicer than spray paint!

-

Whether you are using a wood stain or an oil such as linseed oil, make sure you store your oily rags properly if the oil is combustible. Read the can of oil before using it to make sure that you know how to properly store your used rags. Just a few days ago by brother went to a barn fire. It turned out that the guy who owned the barn was redoing it and left his staining rags on the floor of the barn. The rags combusted and the barn burnt to a crisp. You don't want your shop to end up like this barn! Be careful!

-

Hi,

I have been reading around on site and realized that most of you guys oil your hammers and then wipe the excess oil. I oiled my hammer about a week ago with vegetable oil, the head and handle, but never wiped any of the excess off. Is this going to be an issue? The handle absorbed all the oil. My hammer has a chared handle, so now I am guessing that it went from completely dry to pretty moist. Can someone tell me if I got a problem on my hands? Thanks

-

I am no expert either since I am making my own gas forge too. What I am going to do is out a couple inches of ceramic wool. Then line that with casting. Then line that with ir reflective. The ir reflective just makes the forge more efficient. Hope this helps.

-

You might want to consider one from a company that sells forge making supply's. I am going to be making a gas forge and although it seems expensive, I am going to get a single burner regulator kit from Zoeller forge. Well that is if you are using a single burner. If you need one for two or three or how ever many burners, they sell them too.

-

7 hours ago, NickOHH said:

I used some flat bar wih a couple holes drilled right outside the feet with long lags goin into the stump holds it real tight and I drop tools in the slot to keep em handy when needed .

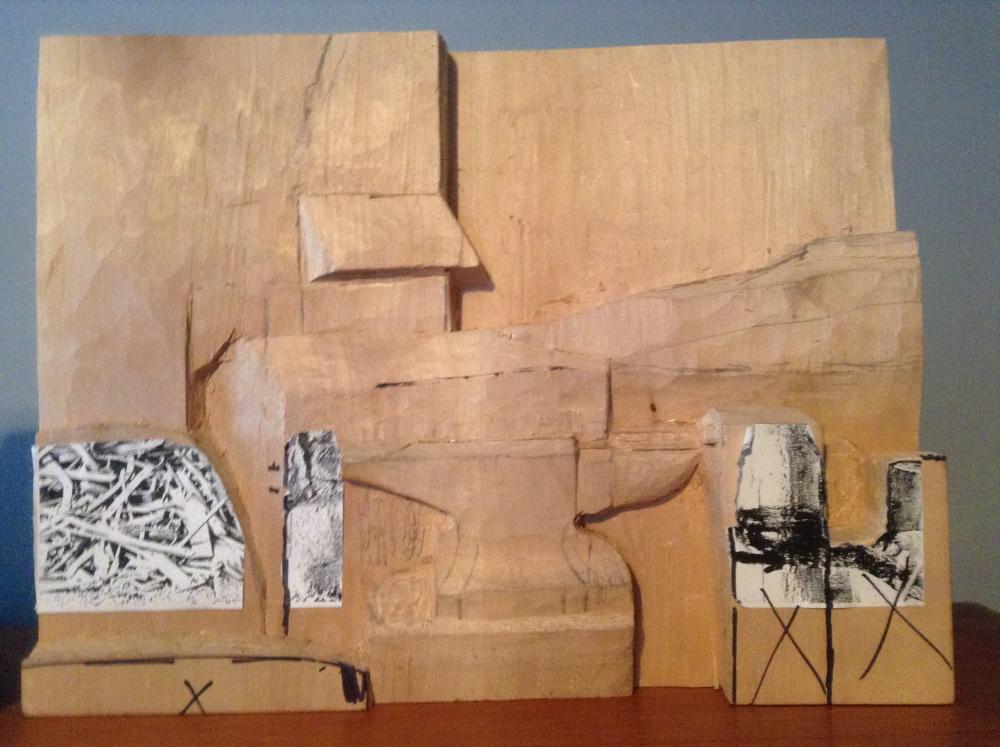

If you are confused by this just look at NickOHH's profile picture.

Also, what brand anvil is that? To me it looks like a Fisher and if that's the case you don't need any magnets or chains becuase these anvils were constructed to be quite.

-

Can you get a close up so we can see the Damascus look? If you haven't etched already, you might want to consider doing so. Great job

-

No one size tongs is best. You can never have enough tongs as I am just figuring out and I'm pretty new to this! Anyways, for railroad spikes you want tongs that will hold 5/8" as DSW said, which is just under 16 mm. if you want a pair of tongs specifically for railroad spikes, check out this link. I'm not sure how well they work, but if they are specifically made for railroad spikes then I assume they will work for their intended purpose. Hope this helps you a bit.

http://www.blacksmithsdepot.com/railroad-spike-tongs-18475.html

-

Alright thanks. I really had no idea how to word this so let me try again. I am making a forge out of a freon bottle with Wayne coes directions. On the forge he a flare at a 45 degree to mount the burner onto the forge. This makes the flame twirl in the forge for a more even heat. On your forge, you connect the burner through an elbow connected to a flange. My question is that how would I connect your burner to my mount? Would I just skip using the elbow and flare and attach the straight pipe in my mount, or is there something else you would recommend? Thanks very much and I hope this is more clear.

-

Hi frosty. I see in your off that you attach your burner to a connected that is connected to the forge with a flare. My question is that I am making a freon forge, and I am going to have my burner connected to a flare that's cut on a 45 and welded to the forge. Does this mean that I can just skip the elbow and flange step and put the piping in my connector? Thanks

On 1/26/2016 at 6:29 PM, Frosty said:People who use needle valves don't use regulators.

Yeah I guess you are right. You would be shocked how much I researched on gas forges and burners! This hasn't came up in my research, but I should probobly research some more. Thanks

-

Well I would imagine cooking over coal isn't the best idea, but I am sure some guys have done it. I know some guys keep their coffee warm on the overhang part of their forges hood.

T Burner Illustrated Directions

in Gas Forges

Posted · Edited by Mod44

Commercial link removed per TOS

Hi Frosty,

I'm gathering the supplies for the burner and had a quick question. Is this the right tweeco tip and right price? If not, where do you recommend getting them? Thanks