-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by templehound

-

It took me 2513, Ceylon ironwood, copper and a month to form this knife, suitable for every day use in the rainforest. Blade was forged from square stock Boehler TWR 1.2513 (...the good stuff from the 70's) Handle and sheath are made from a single piece of Ceylon iron wood(Mesua Ferrea) and the center of the flower is the riveted tang. Blade length is 200 mm and it measures overall 345 mm (13 1/2 inches).

-

Thank You bigfootnampa! The long hole is the option to tie the knife to the belt or the backpack. I used potassium polysulfide (https://translate.google.co.th/translate?hl=en&sl=de&u=https://de.wikipedia.org/wiki/Schwefelleber&prev=search) Thank You Biker Bo! Thanks Gergely! I appreciate it a lot!

-

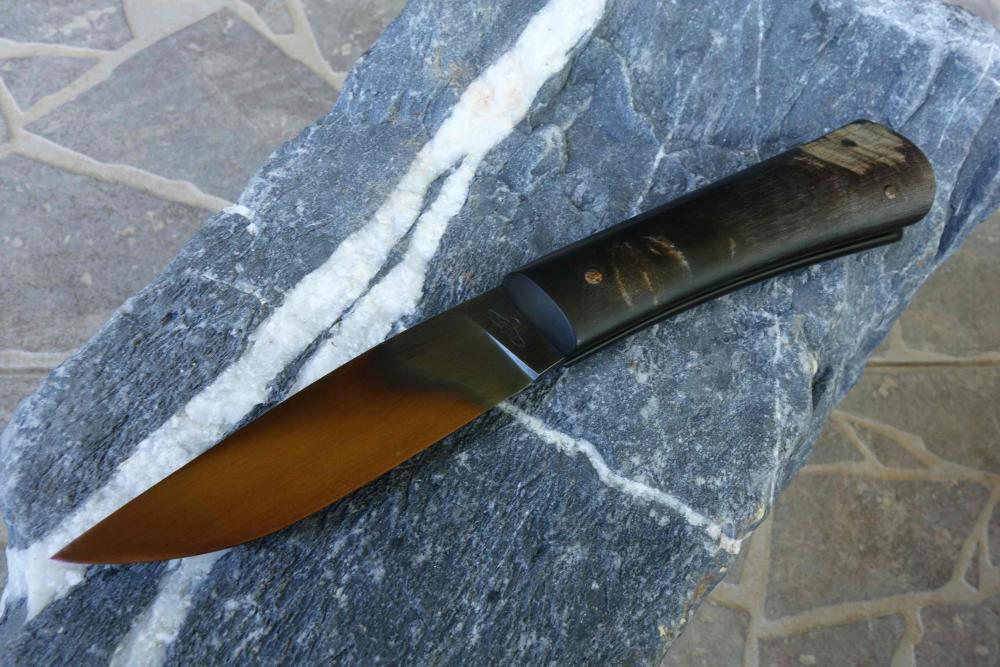

He travelled a long way from Thailand to Austria. 1.2516 (120WV4) blade, forged from round bar, bolsters and pins are copper and Indian rose chestnut for the slabs. Overall length 230 mm. The sheath is made from water buffalo hide.

-

Thanks a lot for the nice comment, Malice!

-

I use a SONY Cyber shot, which is a real good camera . I took ISO 800 and adjusted the aperture a short/fast as possible. Köszönöm, Gergely!

-

Thank You, BIGGUNDOCTOR!

-

In my opinion the handle is not really oversized,....most of the knives of that style have too fragile cross sections of the handle behind the guard. a blade of this length invites to chop sometimes, even if its lacking weight towards the tip, so this handle should have more endurance than more "elegant" rifle knives. Filling the palm well, as a fighter should.....I like it!

-

There is 1.2516 forged from round bar for the blade, the handle slabs are Cobra's saffron (Ceylon iron wood), 6Al4V Titanium for the liners. The spring, clip and other mechanical parts are made from 1.1274 high carbon spring steel. It is a superb steel...even the spark picture of this steel is from special beauty

-

.....well, depends on what kind of attention You are after......

-

Thanks, DC! To me it is both, useful and aesthetic....the reason I made this is, that I became frustrated with the shrinking of some natural handle materials, especially horn tends to shrink a lot. It feels comfortable to the hands as well. it is a lot more effort to produce but it is worth it. Thanks tdaleh!

-

-

Lol......Your reply is most appreciated! Thank You so much, Gergely! Cheers

-

After being excited by this unexpected attention it deserves at least one image. may I present: "The broom".

-

Thanks, JHCC! Thank You boisdarc! Yes, thats the kind of broom everybody swinging around here.

-

Guardless hunter in O7 with copper bolsters and Ceylon iron wood (Mesua Ferrea). Blade length 100 mm and overall 22,5 mm.

-

Well, that didnt turned out as dark as it should(?)...5160 has 0.6% carbon, after forging You have some carbon loss, maybe 04% remaining....that is too less carbon to make the blade really dark with coffee.like I already posted, You need a good amount of Mangan and/or more carbon.

-

Thanks for nice comments, Gentlemen! I appreciate them a lot. cheers

-

Thanks for Your reply!....I tried coffee etching with mono steels and it seems to work ok on steels that have enough Mn,like O1....but cold blueing in general works better. In my experience coffee works on hamons very well.

-

A small utility knife forged from OW1(1.2516, 120WV4) round bar, with Ibex(capricorn) horn slabs, copper pinned and an overall length of 185 mm. This steel is about 100 years in use and it is such a great stuff to make excellent blades.Forges and welds very easy(actually a waste in a damascus billet)grinds and finishes also with very less effort....very good edge holding and easy to sharpen.....http://www.metalravne.com/steelselector/steels/OW1.html....simply a joy to work with. Cheers

-

Aah, singing the blues!...The good old times have gone! .....You feel that, best sign that You are getting old...."old people" always will complain about new times, and in their point of view they are right....but thats not how it works.....remember: "The only constant thing is change.".....besides TV will never change into something good but it will change to ....so there ever will be a" good old time" for every generation....we will make the best out of .it

-

I wrote this in a different thread, and I think it is useful to share it here again. In my opinion there are two kinds of etching, to wash out (H2So4) and coloring(oxidize) steel( ferric chloride, gun blue and other natural etchants like coffee)vine gear and mustard are slow and have uneven and unreliable effects, coffee is the best. Etching with coffee has a few benefits: easy to get, to prepare and to dispose , no chemical handling and waste.No harm to health, no goggles and stupid latex gloves. It also gives better colors and it is no problem to etch twice on already finished presentation pieces(no acid surface line) no harm or damage and discoloration to natural handle materials( well, on snow white Ivory I dont know, haven't tried that yet, but I guess it is no problem, try with a sample) I always take one sachet (minimum amount to buy)which contains 45 grams and mix it with 500ml clean water.....approximately. I do not recommend groundwater, take drinking water or distilled water which has less impurities, minerals and that stuff. The water should have room temperature, about 25-30 Degree C, dont take hot water, it turns a lot of the acids into base. compared to ferric chloride it works a little bit slower the first 10 minutes but then it shows much quicker clean colors, no black, orange or olive complexion/smear what sometimes comes with ferric chloride etching. Another good thing is You cannot over etch so easy...You leave too long in Ferric chloride You get black pit holes, blisters, bubbles and other ugly signs of over etching. A friend of mine forgot a blade in the coffee, remembered it 18 hours later, there was no remarkable damage to the blade surface, just the colors became antique-dirty and changed into black and white instead of black, grey and white.To do some damage it must left in there more than 24 hours, I guess.....but I dont want to try that out, no need for that experience. Very important for having a good etch is, You have to create a good surface. Coarse marks will always show up dark and disturbing..... The knife shown is coffee etched, there are three components in the steel O7(grey), O2(black) and 75Ni8(white), Grit 1200, etching time about 20 minutes. I am no coffee drinker but I like a good fresh, brewed coffee in the morning, ...but this instant stuff You should not drink.....too much acid.

-

Damascus steel chefs knife wip (problem with etching)

templehound replied to Dustin Quade's topic in Knife Making

In my opinion there are two kinds of etching, to wash out (H2So4) and coloring(oxidize) steel( ferric chloride, gun blue and other natural etchants like coffee)vine gear and mustard are slow and have uneven and unreliable effects, coffee is the best. Etching with coffee has a few benefits: easy to get, to prepare and to dispose , no chemical handling and waste.No harm to health, no goggles and stupid latex gloves. It also gives better colors and it is no problem to etch twice on already finished presentation pieces(no acid surface line) no harm or damage and discoloration to natural handle materials( well, on snow white Ivory I dont know, haven't tried that yet, but I guess it is no problem) I always take one sachet (minimum amount to buy)which contains 45 grams and mix it with 500ml clean water.I do not recommend groundwater, take drinking water or distilled water which has less impurities, minerals and that stuff. The water should have room temperature, about 25-30 Degree C, dont take hot water, it turns a lot of the acids into base. compared to ferric chloride it works a little bit slower the first 10 minutes but then it shows much quicker clean colors, no black, orange or olive complexion/smear what sometimes comes with ferric chloride etching. Another good thing is You cannot over etch so easy...You leave to long in Ferric chloride You get black pit holes, blisters, bubbles and other ugly signs of over etching. A friend of mine forgot a blade in the coffee, remembered it 18 hours later, there was no remarkable damage to the blade surface, just the colors became antique-dirty and changed into black and white instead of black, grey and white.To do some damage it must left in there more than 24 hours, I guess.....but I dont want to try that out, no need for that experience. To have a good etch You have to create a good surface. Coarse marks will always show up dark and disturbing..... I am no coffee drinker but I like a good fresh, brewed coffee in the morning, ...but this instant stuff You should not drink.....too much acid. Cheers- 24 replies

-

- etch probelm

- 1080 and 15n20

- (and 5 more)

-

Damascus steel chefs knife wip (problem with etching)

templehound replied to Dustin Quade's topic in Knife Making

This one is coffee etched. steps with belts: 40/80/150/240/ ; hand finish 280/320/360/400/600/800/1000/1200- 24 replies

-

- etch probelm

- 1080 and 15n20

- (and 5 more)

-

Damascus steel chefs knife wip (problem with etching)

templehound replied to Dustin Quade's topic in Knife Making

I recommend a more even blade finish, there are plenty of coarse marks in it.Try a hand finish ( Grit 400 minimum). and then etch in cold instant coffee, it needs a little bit longer than ferrochloride but it is so much better and nicer etch...and no chemical waste at all. Damascus looks very nice!- 24 replies

-

- etch probelm

- 1080 and 15n20

- (and 5 more)

-

Thank You, Daswulf!...it is a locking liner.Can be seen better on this picture. Thanks 1forgeur! I bring the blade to a true 600 grit finish, polish with sisal lengthwise using a coarse polishing compound and sharpen it with artificial polycristalline ruby or ceramics. After this I buff the edge very slightly in a very flat angle, enhancing the sharpness and slowing down corrosion on the bevels.