-

Posts

554 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by MotoMike

-

-

I'm at a standstill presently owed to my lack of ambulation and that the acetylene regulator has a commercial 300 fitting on it and my tank is a 510. Dad rented tanks so when he passed, they went back to the vender. 20 years after that the rig minus the tanks were offered to me. at that time I blew out the regulator ports with air and taped them closed, but they were open for 20 years. Now 20 years later I'm considering their use. I guess it is good advice to have them checked out. Though it runs contrary to my normal MO. I purchased a set of tanks size 3 and Q both still in hydro for at least 5 years and full. Dad had big tanks I don't know the size, but they were at least twice the size of mine. I guess that explains the acy fitting on his regulators. I think I can thread out the nipple and female nut composing the 300 fitting and just replace it with a 510 nipple and male nut.

Thanks very much

Mike

-

I have my late fathers oxy acetylene rig. it includes both regulators and a bunch of cracked hose. 3 torches all cutting. It has been probably 40 years since they've been used. The regulator tank connections have been open. one torch has been sealed to a hose set connected to the regulators, two torches have connections open but the valves are closed. should they still work? Is there some maintenance that should be done? can they be washed down with soap and water. I have some new hose sets and would not have planned on using the old ones. Should I just hook them up and give them a try?

thanks in advance

-

top notch work. A very handsome profile.

-

nicely proportioned. very elegant.

-

will the coolant be water or something else?

-

It is very nice

-

-

In 22 years of copping in a railroad community, I've had my fair share of interactions with railroad police. the company policy is that you can't be on railroad right of way. Because the company cares, the rail police "care" It is just a better practice for them to not have people on their property no matter their purpose. what do they really care about? boarding cars in yards and stealing property from them. breaking into sheds or workshops and removing tools and property from them. removing wire, track or machinery that will cause an unsafe condition. in the world of trains any unsafe situation can be catastrophic. Also living on the Mississippi River, the tracks run between the road and lots of riprap fishing. rail trespassing is happening all the time for this purpose. I never see them much concerned about it. If the person makes it an easy ticket, they might but most of the rail trespassing charges I've seen involved an added charge for something much more serious. When I was a kid piles of rail scrap were in and around the local. existing with weeds growing through them and rusting away. Almost every garage had an "illegally obtained" rail anvil, buckets of spikes and plates and other things that accumulated along the right of way and in the yards. No one much cared. 9-11 has brought new focus to the area. Still in my area it appears no one cares. Does that mean if you are stepping across the right of way to fish, or you pick up a spike out at the edge of the right of way, that you wont get a ticket? No there are pedantic officious people in all walks of life.

On 8/31/2018 at 9:15 AM, JHCC said:...the warning needs to be given...

I suppose. think it could have been handled in a way that allowed further exchange from the OP and didn't chase him away after his first post? OOOOH he got moderated, he got moderated good!

Keep it up and find out

-

I'll be there

-

Thanks Frosty. I just now noticed you made that comment.

Mike

-

I have acquired rail scrap from scrap yards and from business that do repair. Maybe it was said that he was going out and collecting it without permission, but I didn't see it. I've had friends who went and got small contracts to remove old ties and do other work for them. He just said he had access to it.

I got a partial answer to my question how to use it "smelt it into iron"

but why. can you achieve some effect you cant buy buying iron, is there a historical perspective, like a mountain because it is there?

-

In these welded up designs, at least the good ones, are the plates positioned with a gap consistent over the intire surface and then the gap welded shut from the center all the way out to the edge? How else can full penetration be achieved? Is full penetration required? Have some welded only the outside inch and reported good results? I wait with bated breath on the heat treat. since the piece is large and unwieldy, would picking a top plate like 1060 which has a simpler heat treat procedure including the use of water as the quenchant be a better choice. In the case of the 1060, couldn't residual heat be used to temper before a final quench in water?

-

That is some excellent work. I hope to make some small axes some day. I have a Wetterlings that I'm quite fond of which I hope to use as inspiration. Great work.

-

woa.. that just extended my reach a little further from my grasp.

-

-

How does one go about using this? would it be for the historic perspective, or would there be an advantage?

-

Thanks MC. Sounds like you got a good one.

-

MC yep a resurface which I think is somewhat a misnomer. the procedure is more invasive than the traditional because the tools need more room to get in there to do the work. the Bronco Nagurski looking nurse told me that his job was to hold my ankle by my ear. Everything I've seen indicates the traditional is a faster recovery. but the traditional has restrictions that extend beyond recovery. The traditional has a small plastic ball and socket or plastic/ceramic. They are more prone to dislocation and you have range of motion restrictions. I'm at the age where they don't like to do this one, or I should say the insurance companies don't like to do this one as the appliance itself costs 3 times as much. . this is a repair that youngsters who are active would typically get. The Sports model if you will

-

yes, only to change belts.

-

Steve

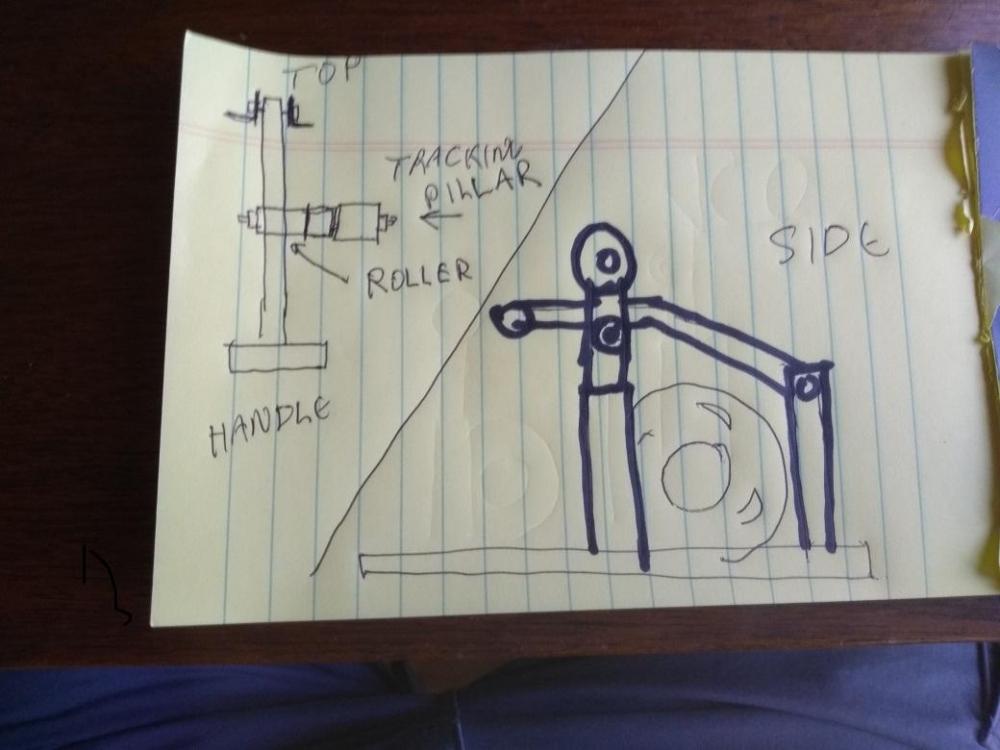

The original plans describe finishing it off with a gear shift knob or similar on top of the pillar to compress the spring for belt change. that would work ok, as I'm essentially doing that now without the knob to change belts. I plan on putting a mount behind the motor composed of a couple pieces of angle iron with an axle at the top for the lever to pivot on. This is to run forward over a roller which I will mount on the back side of the tracking wheel support. plan on putting a t handle on it so I can get to it from the front or the side. drawing not to scale and the details to be fleshed out yet. just to give you an idea of what I have in mind.

-

Thanks Spanky. It is true. Now that all seems in order, it is a relief. I'll admit to being a bit nervous pre op, but it had caused me to fall down a couple times and the pain was up there. Even with the surgical pain, I have more range of motion than I did a few days ago.

-

Ben, hoping this will cover it. Depspite it being the same appliance, it did go quicker and home sooner this time Don't know why. being 7 years older I had some concern. thanks

Hans, thanks for the kind words,

-

3 hours ago, SLAG said:

quote removed

Thanks Slag. It is my second one. it's the Burmingham appliance. 7 years on the other one. no problems.

Jim your advice is well received

Thanks Das

-

2 hours ago, stevomiller said:

Nice job on your grinder, you should be proud every time you put it to use :-) I know that I would be!

Thanks very much Stevo. I've already used it quite a bit and am wondering how I got by without it. It is so useful. In fact, I've not even truly finished it as I plan on a lever to slacken the belt for change. the plans called for a static discharge brush. will that cause the dust to not stick to is so much? Is it really needed?

Is this too small

in Gas Forges

Posted

no problem windows 10 with edge