-

Posts

272 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by DKForge

-

I know I have only been around the site for a couple of months now so take this with that in mind. I would lean toward using it the way it is for awhile. If for some reason you decide it just isn't the size or pattern you want the changes you make to "fix" it can have a negative effect on a good old Peter Wright that others would want and use just the way it is. I understand the need to have a good spot to make a 90. I have a Fisher that has a similar issue to some extent but I have learned to use the whole anvil. I have spots on the heel that are sharp enough to get me a good 90 and it doesn't effect my work any. At the end of the day it's your anvil and you should do what you want. I prefer to see old anvils with history like your Peter Wright left the way they are. Just my $0.02. Good Luck.

-

Hey Flamin S Forge, I appreciate your post. As someone fairly new to blacksmithing I try to carry the same philosophy. While I understand and acknowledge different ways to do things I think for most of us we are in this primarily because we like working with fire, coal or gas, steel and our hands. I am sure there were plenty of smiths in history who did things their own way and it is through them that we came up with new and different ways of doing things. I like your comment to the "gentleman" with the comment about hand crank blowers unless you live around Lancaster County, PA and it was an Amish fellow you were talking with. Thanks again for your post.

-

Christmas Wish List

DKForge replied to rustyshackleford's topic in Blacksmithing, General Discussion

Just a short list.... 1. A set of Scrolling Tongs 2. Assorted Mild Steel 3. A stamp with my touchmark from Infinity Stamps -

Happy Thanksgiving to you and yours!

-

Just got mine today from Amazon! The way it is written is very easy to follow. Being at this for only a couple of months the tips she provides alone are well worth it!

-

Very nice Frosty!

-

Thanks Sam I see what you are saying and really appreciate your help.

-

Sam would you explain what you mean by looking "tired?" I've only been at this about a month so I appreciate the feedback from all who have responded. Thanks

-

Hey all, I made my first leaf keychain fob today. Visually I think it turned out okay for my first try. The question I have though is how thin do you forge the leaf? I think I went too thin because the edges are quite sharp and I would worry about someone cutting themselves when reaching for their keys. I tried filing and sanding the edges and it helped some but I am wondering if others don't go as thin to avoid this problem. Thanks for your help.

-

Anyone have photos of how you carry your tools (hammers, tongs, hardies, punches, chisels etc.) when doing demos or living history type events. Do you use the old wooden carpenter type tool box, buckets? Just wondering as I am starting to amass my tools and wanted to see what others are doing. If this has been asked before please just point me to the right thread. I did a search but couldn't find anything. I like making things versus buying so any homemade ideas are most welcome. Thanks

-

Feedback requested on first piece

DKForge replied to DKForge's topic in Blacksmithing, General Discussion

Great looking forks Chuck and thanks for the comments. -

Feedback requested on first piece

DKForge replied to DKForge's topic in Blacksmithing, General Discussion

Thanks all I appreciate the feedback and am adding your suggestions to my list of things to keep in mind for the next time. I am totally hooked on smithing and am glad for all who are willing to share their time and experience to help a new guy. I learn something new every time I pick up my hammer and strike some hot steel. Thanks again -

Three weeks ago I first put hammer to iron. Been making s-hooks for the smith I've been watching and learning from on the weekends. Yesterday was kinda slow at the flea market where we do demos and sell Tri-pods, pig tails, oyster shuckers and dinner bells. I saw a piece of 1/2" round about 4 inches long left over from a dinner bell we made and heated it up. This is what I ended up with. Its a serving fork about 9 1/2" long. I am looking for constructive feedback since I am just starting out so feel free to let me know what you think. I appreciate your time looking and your comments.

-

Chris I just built a brake drum forge today and picked up the piping this morning. I used 2 inch black steel schedule 40. You won't find it at the big box stores I had to go to a plumbing and drain pipe supply company. I used a 2 inch flange, a T, 2 inch nipple, 4 inch nipple and 6 inch nipple. It worked real well. Good luck and check your yellow pages for pipe or plumbing supply house that carries schedule 40 black pipe.

-

No tools for the hardy, it is a 1" so I will have to make some or look for some good deals out there.

-

Thanks everyone for the replies, I scrounged a brake drum for my fire pot and now just gathering some steel to make a table. I have a bunch of ball peen hammers from small to 2 1/4 lbs and my dad just brought me a 2 lb cross peen which was my grandfathers. I'm 40 so its been around awhile. He also brought me a really old set of tongs that should get me started and now I am only looking for a rounding hammer. I'll keep you all informed of my progress.

-

FieryFurnaceForge, check your PMs. Thanks

-

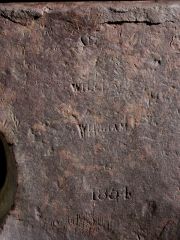

Hello, I just introduced myself over in the introduce yourself forum but wanted to post more here. First I appreciate all of the awesome info shared on this forum. As a lurker for a about a month I have already learned so much. I have always enjoyed watching blacksmiths at reenactments and historical parks and said that someday I would learn to do that. Well I have started spending some time with a local smith watching and learning from him and last week I purchased some of my first tools. I wanted to post them here to see what you all think. Just so you know I don't mind honest advice and always will accept constructive criticism for what it is, a way for me to learn and look at doing things in a way different than how I have been. Ok so here is my purchase story. Listed on Craigslist in a town about 3 hours from where I live. The gentleman selling did not have a camera so if I was interested I would have to drive three hours sight unseen. He said the items were his grandfather's and have been passed down three generations and his son is not interested in using them so they were for sale. With that info I hoped they would be worth the gas money and six hours of driving. Here they are... First My Anvil, William Foster Dated 1854, 212# based on the 1 3 16 on the one side of it. You can see the crown at the top, William very clearly marked twice and the date 1854 with a B at the bottom on the other side. The ring and rebound are really good all around, no dead spots that I can tell. There are some chips on the edges and a lot of dings on the face and horn but it is overall very flat meaning no sway back. It is 24 1/2 inches long from tip of horn to tail. The face portion is 14 1/2 long and 5 inches wide so plenty of space to work around the edges that are questionable. It was laying in the dirt covered in weeds but she cleaned up pretty nice and I think she has plenty of life in her still. What do you think? Next the blower, Champion blower, over 14 inches across, on the stand with a Midway Spiral Gear Drive. It is super smooth and blows a lot of air. Very quiet all you hear is the air coming out. I did have to clean some mud wasps out of it because when I first saw it, it was stuck. Well it was just due to the wasps nest but now it is running as perfect as I can imagine. When I let go it continues to rotate about 3 revolutions. Last is the post vice. It is very heavy and after a bunch of WD-40 works great and the threads are not stripped at all so works very well. Still had the spring and clamp with it. There are more photos in my album on the IForgeIron Gallery. So those and a small shoe anvil came home with me from the nice gentleman who lived three hours from home. So what would you pay for these items? I think I got a pretty good deal as I got it all for $425. Again I'm glad to have joined your community and look forward to talking with you all soon.

-

From the album: Tools

-

From the album: Tools