metal99

-

Posts

362 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by metal99

-

-

This is my first knife. I forged it from a spring steel rod. My forge was an oxy acetylene torch with a rosebud tip ;) I used the vice for an anvil.

-

Thanks for the info, did you grind post HT to prevent warpage?

-

That's a fantastic looking knife! What did you do for heat treating?

When I want a finish like that I do the exact same thing as you did but I finish it off with scotch brite. I found it gives a more even scratch pattern. -

Nice looking anvil whatever it is I think the price was fair. If that were my anvil all I would do with that hardy hole is leave it alone. I would take a plate if steel maybe 3" square and cut the square hole in it. Just set that over the hardy before you put the tool in. I don't know how well that would work but it might be worth a try. That's just me tho.

-

Just seems like there are to many hammer marks on the base to be cast iron like a Trenton and the feet are a little different then mine. I could be wrong tho, just my best guess really.

-

I'm no expert but it doesn't quite look right to be a Trenton and it appears to be forged steel? Someone correct me if I'm wrong, still learning. Nice anvil no matter what it is. Safe to say its no ASO either.

-

Happy new year demid! Your work is beautiful.

-

Looks good :) I love desert ironwood.

-

I think I read about the printer ink somewhere. I might have to attack my printer soon :)

-

Thanks Zengineer, I put a lot of time into this knife.

Private Entrance, I have some powdered pigment that I want to try out some time. From what I hear, powders are the best for epoxy unless your using epoxy dye of course. -

Absolutely stunning piece, you should be very proud. And more orders! That's a great indication of the job you've done.

Out of curiosity, what's the going sale price for these?

Thanks for the compliments. I sold this one for $350

Loneforge, I have been tempted to try dyeing the epoxy. I was thinking about glueing my scales on and then using a tooth brush to get the epoxy out of the file work then filling it with the dyed epoxy. That way you know there won't be an adhesion issue. For the mosaics I have made I just used straight epoxy with no color. If you look real close you can tell its not black but from a couple feet away you can't tell. -

I filed it into the spine then I used cold blueing to make it black. When I glued the handle slabs on I made sure that the file work got filled with epoxy. After the glue was dry I sanded the handle level with the spine to reveal the file work.

-

That's a fine looking anvil and not a bad price. Good score!

-

Bocote is a fairly stable wood. I would just give it a nice oil finish if stabilizing is out of the question for you. With any natural wood handles its always best to wash them by hand and not submerge them into water.

-

That's probably the best Vulcan in the world now lol. Looks like you did a great job. I'm sure it will serve you well for years to come.

-

You should be able to get a decent anvil for a lot less then that, or do you want a brand new anvil?

-

I'm no pro but I would say you could get by on a 77lb anvil. I use a 100lb anvil and it works pretty good.

-

I'm not a razor guy but I have seen quite a few of them made from 1095. I know 1095 can make a pretty good blade from experience.

-

That's pretty cool man. Great looking knives!

-

Nice looking knives man! I've always like the look of a file knife. Did that farriers rasp harden up well? My dad has one and I was thinking of making a knife with it.

-

Thanks you guys, it means a lot to me. I have 16 more ordered so I will be a busy man for a while. I can't wait for spring to get here so I can fire up the forge again! In the future I want to forge all of my knives so next summer I am going to forge a bunch of blades and finish thin during the winter.

Do you guys know if heat treating outside in the winter would be a major problem? I have a bunch of blades made from 1084 that I need to heat treat. -

Gabriel, I completed my first knife on march 22nd 2012. I'm new to knife making but a lot of the skill my dad tought me from building guitars really helped me in knife making.

Thanks for the compliments everyone. -

Oh for sure it can have carbon, you just never know how much. It just depends on what they used to make it. The chances of it being very high are slim tho.

-

I'm no expert in heat treating but wouldn't welding three bars of wrought iron to one bar of medium carbon leave you with a piece of steel with very low carbon because of the carbon migration?

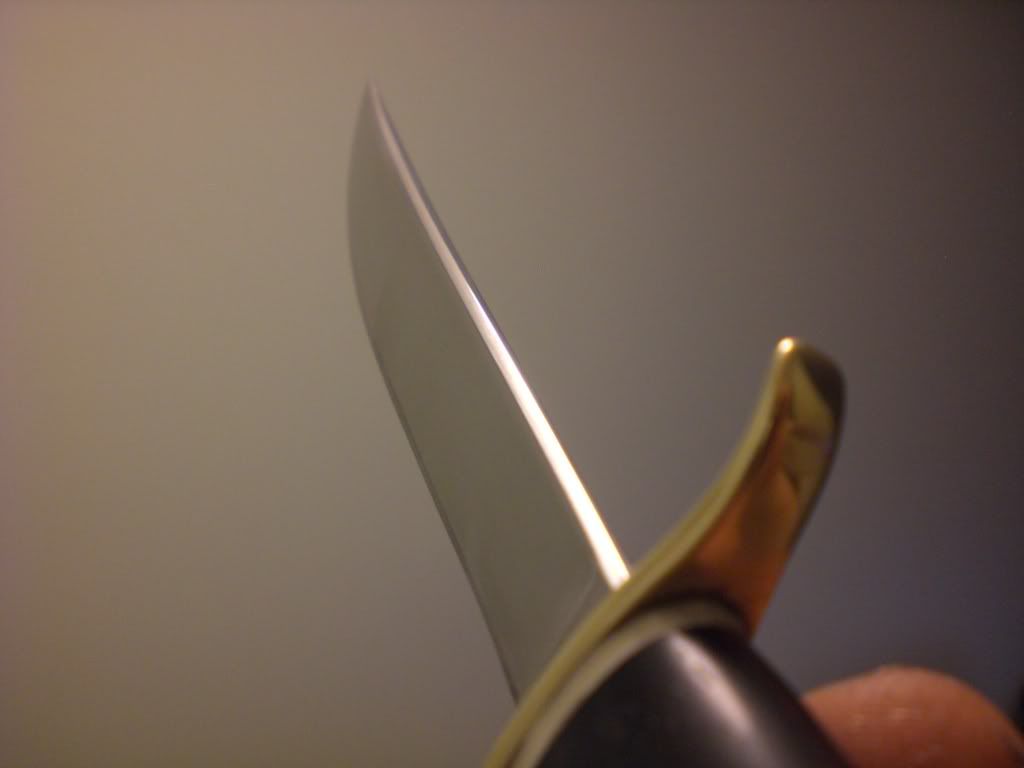

Persian style subhilt fighter

in Knife Making

Posted

I really like the style! Good job man. How long is the handle?