-

Posts

583 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Nick

-

Switching from coal to charcoal

Nick replied to Nick's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

260 miles, though Traverse City is closer than Flint (the last load of coal I got at Streat Fuel because I was in Saginaw visiting family). -

I suggested that but the customer didn't care for that finish, he wanted something rougher and black.

-

Switching from coal to charcoal

Nick replied to Nick's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I've tried all the feed and stove stores in the area, wood heat is very popular here but not coal at all. I guess because of location it's just not economical to ship here (mostly isolated by the Great Lakes, rural, and not on the way to anywhere). I have found a slightly better deal on coal from IL, shipping is still high but it may be enough to have both, we'll see. Still have to go to Upper Lakes but we only have one car so it'll have to wait until next week I think. -

Thanks for the suggestions. Stainless would certainly work, and the finish on that mug is great.

-

Switching from coal to charcoal

Nick replied to Nick's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Yes, I guess I haven't been including enough for fuel. <_< I also spent more time than I should have trying to find it closer than Green Bay. -

Switching from coal to charcoal

Nick replied to Nick's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Thomas, I am in the UP. I've talked with some other smiths, most around here use gas or coke. I have thought about getting together and ordering, if several of us order as a group we may be able to go through Reiss or Upper Lakes in Gladstone (which is close). If I decide I like charcoal I'll think about making it. It wouldn't be a problem here, I live out in the middle of the woods. -

I'm working on a belt buckle, and am having second thoughts about the finish. I was going to paint it, which I've done on belt buckles in the past, but paint chips over time and I'd like something more long-lasting that won't rub off easily on clothes. My next idea was a beeswax and linseed oil finish, coated with paste wax and dried. I've used this on some other pieces and it seems like it would work but I'd be interested in other opinions.

-

Coal has become my personal unobtanium. The two coal suppliers closer than 200 miles won't sell to individuals (I'm going to try them one more time just in case), I don't have a truck to go down to Green Bay, and even if I did or could borrow one the coal's not great and gas isn't cheap. Having it shipped is not an option due to price, either. I'm scraping the bottom of the bin. Charcoal I can at least get locally. The cheapest I've found so far is $14 for a 20 pound bag. I'm not sure if it will actually be cheaper in the long run than even having coal shipped, but I need something right now, as a stop gap if nothing else. I've got a couple commissions I'm working on and I've been trying to figure the best way to get more coal with no luck. At least this will give experience with another fuel and something to work with while I continue to look for coal nearby.

-

Nice, what did you finish it with?

-

A sleighfull of coal. A big sleigh. Getting coal here is a real bear, and as much as I'd like a new chop saw or a little giant or a belt sander, I can't do much without fuel.

-

Thanks, gents. I was pleased how they turned out, I was worried something was going to go wrong when drilling the joint for the rivet, but it came out just right. My 4-year-old pushed the pedal on my drill press to drill the holes, he was very proud that he helped make them. Davor, I didn't realize how small the originals were either at first until I started looking deeper. I saw one that was over an inch shorter than mine, very delicate and graceful. Frosty, thanks, I'll do my best :)

-

These are a little pair of ember tongs or a 'smoker's companion', from the mid 17th to 18th century. Unlike the large pipe tongs kept at the hearth, these are only 4.75" long and so are portable. Some had a hardened upper arm that could be used as a fire steel, but I wanted to get the joint right first. I made the male half a little short, but there is very little play in the hinge. The female half was started with a hacksaw, then opened up with a thin chisel and forged to shape with a thin shim. The upper arm was shouldered at each side of the joint and the leaf was forged down then filed to clean up. The spring is from a hacksaw blade. The end of the lower arm is a pipe tamper.

-

From the album: Untitled Album

A fire striker based on one from the Oseberg ship, c. 850 AD. Three pieces welded together, one high carbon and the other two mild steel.© Iron Bay Forge

-

From the album: Untitled Album

Viking era striker with figural dragon head decoration© Iron Bay Forge

-

I had the feeling it was salt buildup from decades of brine.

-

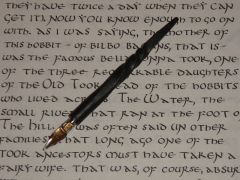

Thanks, Yellow Hammer. I like the idea of the pen holder. GNJC, I'm a regular contributor to the Handlebar Club's online forum though I'm not a member of the club itself. I might join up one of these days, though. Jeremy, those are outstanding! A tiny piece I've been thinking about is sewing needles. I did some reading on excavated needles from Anglo-Saxon settlements, some were punched and some were welded.

-

This is the smallest thing I've done in steel. From end to end it's about the size of a nickel.

-

From the album: Untitled Album

Viking-era fire striker, forged from a spring tooth harrow tine, about 2" long (the same as the originals). -

From the album: Untitled Album

Forging keys. One half-forged, the other done but needing cleanup and cutting the bit.© Iron Bay Forge

-

I bought an old iron from St. Vinnies for two bucks recently. Works great.

-

How did YOU get started smithing?

Nick replied to nankbrown1227's topic in Blacksmithing, General Discussion

My second semester in college I took blacksmithing as an elective. It sounded interesting (I was a history major, not art), and I was lucky to get in. Over the next few years I took several more metalsmithing classes in the art department, and I built my home forge right after taking that first course. -

That was a great video. I liked the bending jig on the near side of the anvil for forming the eye. A red hot axe head is something I never considered for lighting my pipe.

-

New to blacksmith...need advice on anvil and forge

Nick replied to Tacuff1414's topic in Anvils, Swage Blocks, and Mandrels

I would take the Hay Budden, personally. A bit more mass and better edges, and if the blower doesn't work and you can't fix it you can move it on to someone for parts or repair and make a little back. -