-

Posts

290 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Mudman

-

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

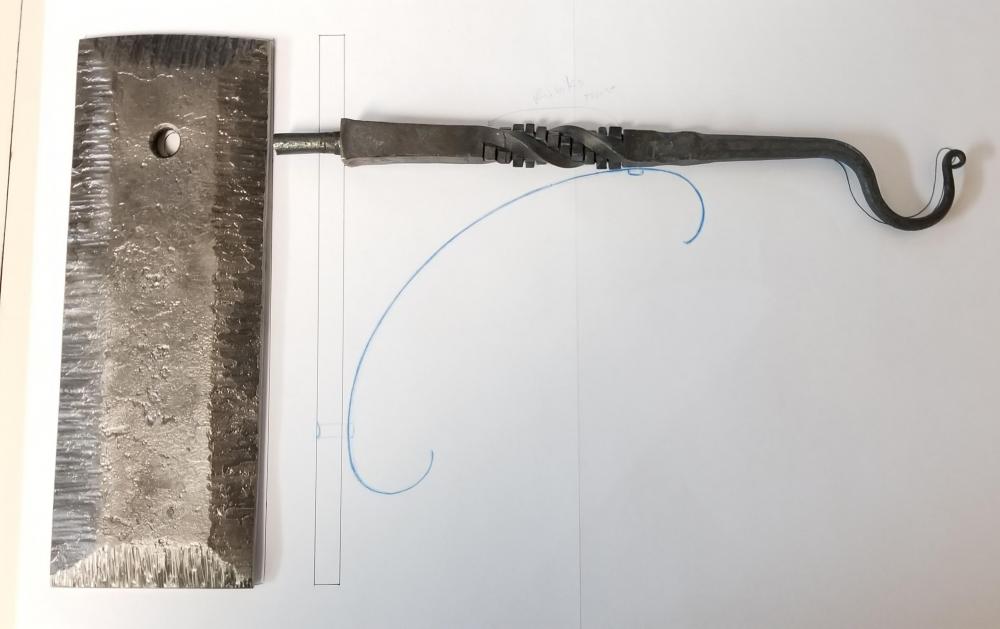

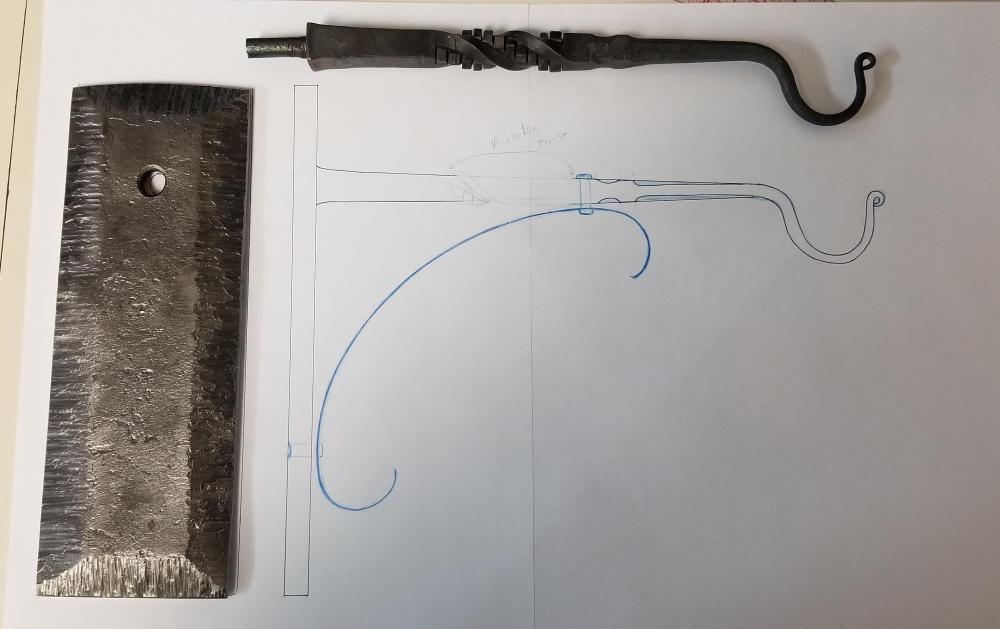

Deciding on how I want the lower support. Sorta deciding on this, but some feels a little off. Any suggestions? -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

metaldrms: awesome hammer Daswulf, I really dig it -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks jlpservicesinc. The tenon kept getting wonky on me, had to keep correcting it. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

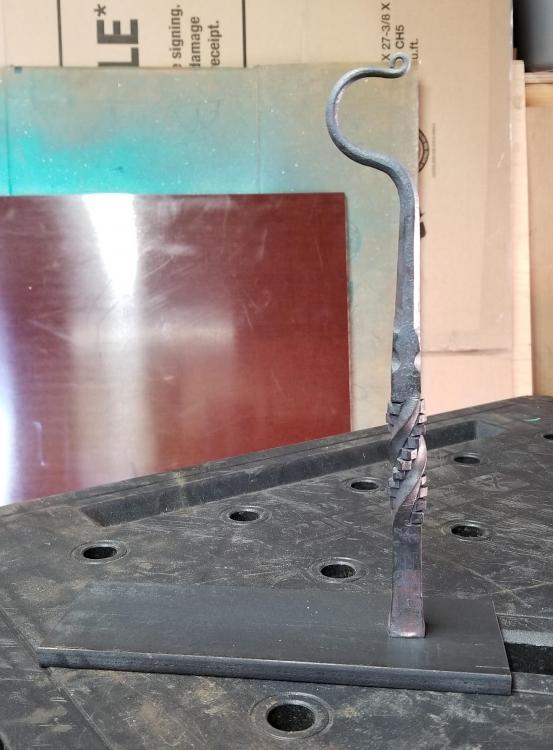

First time with tenon and making a lamp hook. Still need to work on the mounting plate. But pleased with it so far. Upsetting the tenon area was a little tricky, I had a monkey tool, but the bar kept warping on me. Looking back at it, I'm assuming it was because I didnt isolate the heat enough. So I ended up using a bolster plate, that worked better for me in this case. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

ausfire, love the billy hooks. Alexandr... what everyone else said. You do impressive work. -

Flat twist Blacksmith basket..

Mudman replied to jlpservicesinc's topic in Blacksmithing, General Discussion

I REALLY like those! -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks pnut and jlpservicesinc! alexandr, incredible as usual. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thomaspowers: haha thank you, I'm currently in search of a suitable wand. Daswulf: You knocked it out of the park with that, I like it a lot. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Finished up some wall hooks today, they had been sitting around in the exposure and rain for about a year. Then this sweet box of joy arrived today. I had been wanting a new apron for the last 6 or so years, my old one was long before I even attempted forging. Its served well, and continues to. I only had two complaints, one was the split hide. It loves to vacuum up grinding dust. The other was the neck strap, pretty annoying on a warm sweaty day. The new apron is from Forge-aprons and made from water buffalo. Very soft and slick. This is my first time with an apron that uses the cris cross straps, and boy what a huge difference in feel right away. The extra sizing around the chest should help more with wire wheeling, I've had several scenarios, where the wire flies off and gets embedded in my shoulder/chest area that the apron didnt cover. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

I dig it das -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

I like those a lot ausfire. What are these "mm" measurements you speak of? =) -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

jlpservicesinc, thanks. I often attempt to eyeball how much will be lost to scale, although it flies out the window as soon as I start. Sidetracking happens often with me. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

haha thanks ausfire. That's definitely on the list of things to do. I'd like to find the sweet spot for cutting threads for bolts. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

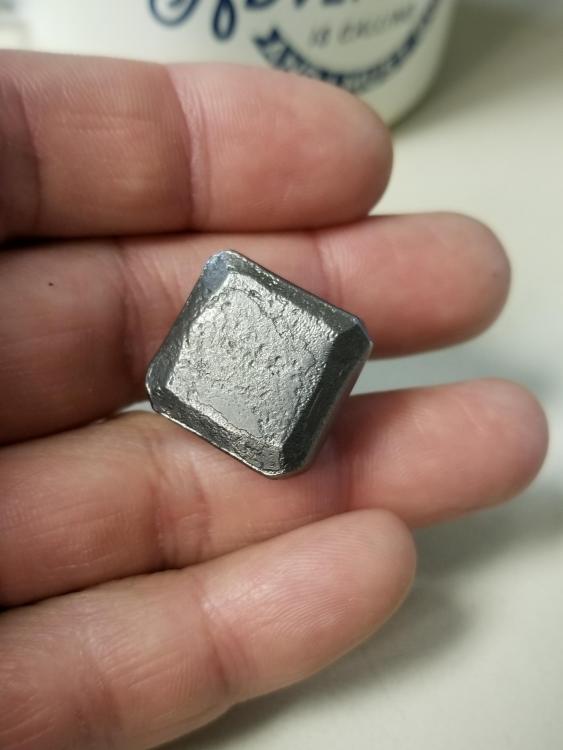

Forged my first bolt today. Square head with some chamfers. Made the base stock a hair too thin before cutting in threads but it still works. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

stellar work peeps -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Alexandr, your work is incredible! +1 to what ThomasPowers says. Although I'm terrible at bottle openers, using this method has really helped me proportion it well. I'd tried a few times by eye afterwards, and always end up going too far. If you don't want to use a quarter, a washer of similar or equal size works well also. Anything of similar size really, so long as it doesn't burn. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Any pics sfc? -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks jlpservicesinc, now I'm less likely to bump into that angle iron. Although I always wear steel toe anyhow. The tongs are made from A514 If I'm not mistaken, ballardforge works on bridges. From what I have gathered, that steel is quite common on bridge use. For how big they are, I'm surprised how little they weigh. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

First time with the rubik's twist. 3/4" was fun 1" became considerably more difficult. Followed by the 1.5" being ridiculous. I couldn't twist passed this point at near dang near yellow heat, 24" twisting wrench, and all of my body weight. Going to need a bigger wrench. Also finalized my vise stand, added a socket for the post leg, and some extra support, along with matching shop color. Annnnnnd some beautiful tongs from ballardforge. 1.5", 2", 2.25", 2.5", and 3" These will be for holding some really big hunks of steel, to attempt forging some skulls. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Coming along nicely jhcc. -

Show me your Bottle Openers!

Mudman replied to Arbalist's topic in Blacksmithing, General Discussion

+1 to what Das said. lol -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Excellent work everyone -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Brilliant, I was going to say hand chisel. That would have been quite time consuming. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

ADHD that's superb, what did you use to texture the petals? It looks much finer than a crosspein -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frosty, it's been a long waited project. I've had the materials to build for a year. Although it makes more sense to have tongs and hammers next to the forge, unfortunately my smithing shop is outside in the elements, and I'd prefer not to leave them exposed. I only have time to work on one or two projects at a time. So really I only have to grab maybe 2 hammers and tongs to start my day. I feel safer having them in the garage anyhow. A separate rack just for tongs is tempting, but right now I've only got a handful of them. Sorry to hear about your tooling growing legs. It's things like this, that keep me from inviting people over. Only person allowed around my shop is 2 or 3 people, all of which I trust dearly.