Gayle Brooks

-

Posts

323 -

Joined

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gayle Brooks

-

-

Gunters sell an oil quench designed for such a thing. I have a 5 gallon bucket of it, works great. Doesn't produce the smoke like the motor oil. The most I have seen react from it is a little flash of fire. Also I have not had a fire start on the surface like I have seen from the motor oil.

Email em @ brad@g3blacksmithing.com Tell them Rory recommended them to ya.

Hope it helps :) -

here is mine!

-

Zipp Products,pneumatic tool, vibration reduction air saw, shock reduction air hammer, air hydraulic riveter, industrial air saw, chipping hammer, universal swivel air inlet joint, low backlash planetary gear reducer, air sander, air file, air impact

I have a version of this. Its an air hammer with an attachment. I modified it when the particle board diaphragm broke with a metal one I made. That was 6 years ago. -

oh and I forgot to mention, they have a yahoo group that they do use. People post questions, events, etc.

RMSmiths : RMS OnLine

Im Rory by the way. Hope to see you around :) -

Elizabeth Brim is noted for mastering this technique if anyone was looking to research this.

Master Metalsmith 2009: Elizabeth Brim -

Heya Ben! Join Rocky Mountain Smiths. I know they are going to have a workshop soon in Erie. I believe its geared for people who want to learn. They will have a forge setup with an assistant smith who will help direct and answer questions.

Rocky Mountain Smiths, Colorado Blacksmiths -

I hope the work inspire others as much as what I see has inspired me. So dont be shy about things you make.

-

more like inspired.

the fold and weld technique was what I used, though I was limited by the handles. For viking period axes they are a bit on the exotic side, and the handles are wrong. Since then though I have traded the small war hammer and a large axe for a wood lathe with tooling. I'll start turning my own handles in time.

Thanks for the compliments :) -

Received this in the email from a fellow smith. Thought I would pass it along.

Short article about the this guys experience concerning brake cleaner and tig welding. Definitely read, takes 10 min and could possibly save your or someone else's life.

Brake Cleaner = Phosgene Article

August 2009 issue of American Iron Magazine

Photo used with permission of Steve Garn (author).

I spoke with Steve and weeks later he is still recovering. He has some damage to internal organs and breathing problems that will remain. We wish him well and thank him for allowing IForgeIron to use this article to inform others of the dangers that exist. -

wow thanks for the compliments!

Yes I used the torch to give the handles that color.

The next war hammer could easily have a slight curve in it! good point. -

These are going to an Irish Festival.

That hatchets have wrought iron bodies with 5160 forge welded tips. The war hammers are w2. Everything was annealed, progressively hardened, and heat

treated after the forging.

Enjoy!

-Rory -

when I was little I was very concerned about doing the trade with my dad. He asked why and I said "I don't want pop-eye arms."

-

just a few inch's long and grind a little edge. take a some of it and quench one in water and one in oil, temper them.

I am guessing heat to non-magnetic?

Also I have never heard of someone color blind not being able to do spark testing. If there is alot of tungsten wont be much spark just dark red (in that I can see it being difficult.) Otherwise its looking at the stars of the sparks, how many there are, how they break, where they break, length of their tails, etc. And using a known to see how it performs. I would give it a try if you could as well as the heat treat test. -

I had taken a class Rob Gunter taught that was mostly heat treating. Harbor freights ballpeens are w2 and that is coming from the the store rep he had contacted. Thats just some control about where you buy the tool. Im sure other ballpeens could/are different metals.

I had noticed that my blade moves during the normalizing process while in the vermiculite. Every time I pulled it out it would have a rack in it. I would straighten it back up and do the normalize again until that blade didn't rack. Anyone else have this situation? It took at least 2 normalizing processes until it stopped racking. -

nice. Heres mine

-

ohhhh ya I get ya. rlarkin has got it

-

from the pic hard to tell anything about it since the pot is most important. Dont see a klinker breaker and wondering how the trap on the bottom works to clean out the pot. Is that a shelf right under it? It might be difficult to clean out your fire. If its cheap you can always fix it. I know blowers are getting hard to find where I am at.

-

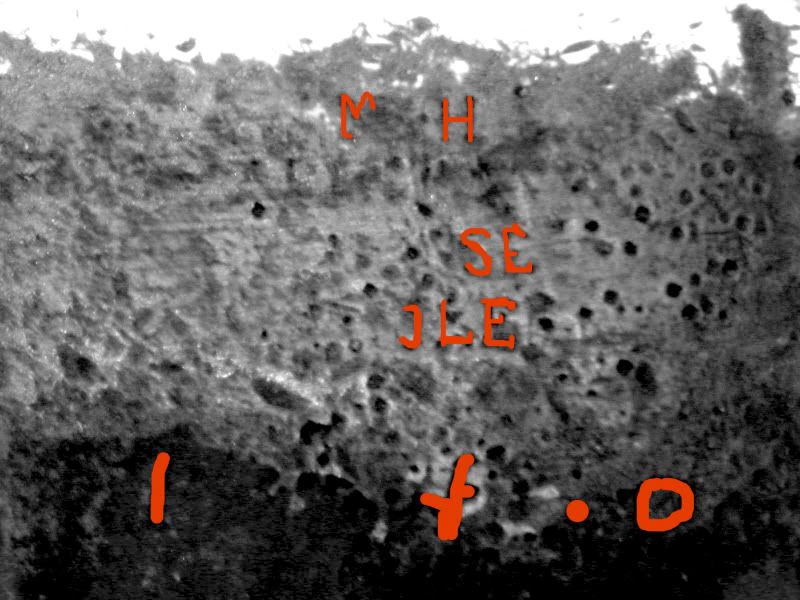

I opened up your pic in photoshop and did some CSI stuff. I agree too and comparing it to the other mousehole brands the "E" particularly fits. Below I marked in red what I thought I could see.

ref pics I was looking at

http://www.martinsmarket.com/images/anvil_clsup.jpg

Your pics

Hope it helps! -

my experience, with a similar situation, was to many heats and/or soaking in the fire to long. I got the same cracks as in the pics.

Hope it helps! -

more mass as well. Can make the same shape just thicker.

-

A buddy of mine made this. Great reference.

-

I tigged material back on that spine you are talking about. Cleaned it up and made it fit in there nice and smooth. No problems nor cracking. Being that its purpose, like you said, was to keep it from spinning. And once the pressure builds up, all that force is on the "face" end touching the vise and not on that spine.

-

Hey Greg! Im in Pine!

Should look up RMS and join up the local organization. Its $30 a year with 4 newsletters. They got a yahoo forum too. Just puttin it out there! -

I've rolled similiar stuff. I made a "sweep" that I welded to the table. Its fairly large (1/2x 1) that was rolled in the roller. Then I started angle iron over the swedge block, getting the curl started, then heating up the first 1/3 (not the whole thing) I bent and clamped it to the table and ran a hammer inside the angle so that the "up" leg was going back to 90 (hammered) to the sweep. Also used bending forks to "pull" the angle iron into the sweep.

In all its small steps or the angle will collapse and be a "v" shape not a "L" shape if you cause it to move to fast, especially the light stuff.

Hope it helps!

-Rory

hammer hawk

in Axes, Hatchets, Hawks, Choppers, etc

Posted

another Ball peen conversion.

Is my first curly maple handle. I reinforced it with a 3/8" round bar through the handle from what I read these dont make the best working handles. I welded a rivet to the top of the round bar, a 1/4"x20 thread on the bottom and tighten it up with an acorn nut. Goes to a new owner next week.

Enjoy!

Oh an some RR spike knives for xmas gift.