billyO

-

Posts

549 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by billyO

-

-

5 hours ago, BillyBones said:

Billy, how did you make the mushrooms?

I forged the chanterelles about 8 years ago and used the socket end of jackhammer bits (a NWBA member used to have a contract sharpening them and would bring buckets of scrap ones that were too short to the conferences).

The other smith did the other mushrooms and she used 1/8" flat bar that she forged into various sized discs, dished them in a swage block and the welded them to round stock. -

Made a bit of progress on the base for the critter.

-

On 4/27/2024 at 10:15 AM, Ridgeway Forge Studio said:

Billy - can I 'borrow' that idea? I love the way it came out and how it looks.

Of course, that's partly why I posted it.

On 4/27/2024 at 11:25 AM, Frosty said:The snail turned out really nice Billy, thanks for the WIP series so we can copy it more easily.

Thanks, Frosty! I'm hoping to do more of these WIP things. I need to remember to take pictures more often.

On 4/27/2024 at 5:34 PM, Rojo Pedro said:Love the snail Billy. Super well done!

Thank you, Pedro. It was a good day.

On 4/28/2024 at 4:05 AM, jlpservicesinc said:BillyO, nice forging.

Thanks, just trying to keep up with you.

14 hours ago, bluerooster said:

14 hours ago, bluerooster said:I think that snail is the "bees knees'. And the log on which it rests.

Thanks, bluerooster. Haven't heard about bees knees for a while. The log was fun, mostly plasma torch work, some welding followed up with a rosebud to melt the welds to smooth them out. I'll try to remember to get a picture before it's all together.

We're going to try to temper color the various pieces. We have the log, a vine twisting over it, a small flower, a couple of chanterelles, a bunch of button mushrooms, some other leaves, and a small critter hiding under the log. -

Hello all. It's been a while since I posted anything here. I hope all is well with everyone.

Another artist and I are doing a collaboration for a "Fruiting Bodies" exhibit next week mushroom themed, so I thought we needed a snail. I'm rather pleased with how it all turned out, better than expected, close to as planned, and went smoothly, almost like I had done these before.

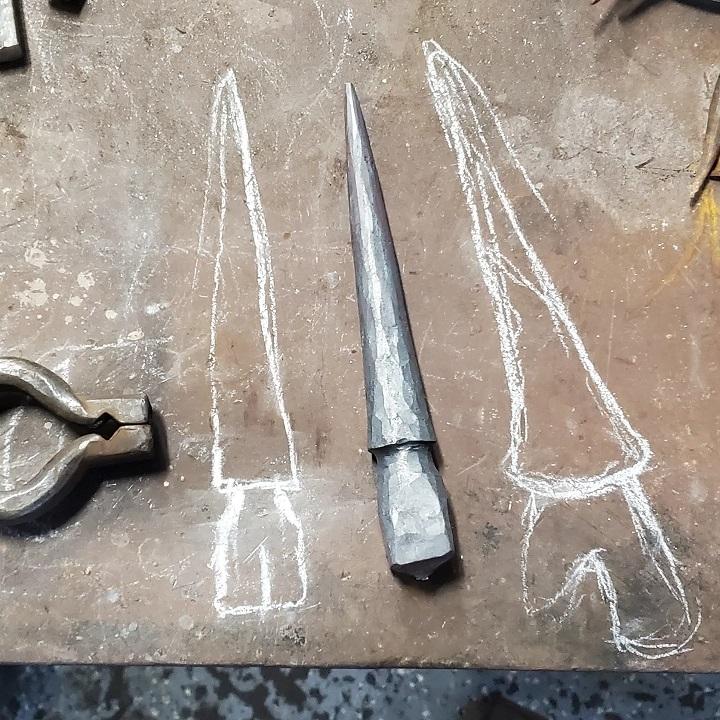

Starting stock was a bar of 1" square:

If only every day of smithing was like this....

-

On 2/5/2024 at 9:40 AM, Buzzkill said:

I think it's the health care industry version of the national chains squeezing out the "mom and pop" grocery stores and gas stations.

As a former Physical Therapist, this is true. As is the fact that an ever-increasing number of hospitals and doctor's offices, as well as more and more industries and business in general, are financed by private equity where it seems the only thing that's important is increasing returns for investors. This has driven away a lot of practitioners who got into the business because we liked helping people, not because we wanted a large salary. So instead of practitioners who spend their time improving their skills in treating dysfunction and disease, what you are left with is a bunch of practitioners who are thinking primarily about how their decisions affect their reimbursement rate, not on what's the best for the patient.

Oh, and let's not forget that these same private equity firms hire managers who are only interested in numbers and force practitioners into unrealistic metrics, like maintaining an 85% productivity rate, which means that we have to be able to bill for 85% of the time we spent with the patient.

Rant over, go forge! -

Hello all. I hope the warmer summers are treating everyone else better than us here in the PNW without A/C...

I recently was given the opportunity to do a large sculptural commission with the instructions that "money is no object". After a little discussion, it looks like the customer is willing to buy our shop a forging press as a deposit, so which one?

I have quite a bit of experience with using Uncle Al's 25-ton H-frame and with Coal Ironworks 16-ton and 25-ton, but most of that work was for making damascus billets and canisters, and outside of speed, there wasn't much of a difference in their abilities to forge billets and kitchen knives.

I've heard a lot of good things about the Gilmore 50-ton press at the NWBA conferences over the years, but I'm not sure if this is because they are superior machines or merely because he is a fellow longtime member of the NWBA...

I'm also a little concerned that the H-frame might limit access to the dies for some operations while making sculptural pieces. Has anyone with an H-frame press had any issuse with the frame getting in the way, limiting access to the dies?

I appreciate any input. Thanks and stay cool!

-

On 3/5/2021 at 8:01 PM, Mattstree said:

Am I thinking about this correctly?

Do a search for san-mai. It sounds like this is what you folks are talking about.

On 3/5/2021 at 8:01 PM, Mattstree said:Obviously I'm almost to beginner.

I'll warn you that san mai construction is a lot harder than it looks. It takes quite a bit of skill to keep the core (edge) centered in the blade during forging.

-

2 hours ago, HondoWalker said:

When I bought my house one of the clothes hanger rods was 5ft of 3/4 inch steel rod. I have been using that. Have no idea what kind od steel it is.

Based on this, I'd like to change my answer to: you got lucky and probably ripped them off. Unless you did some testing and made sure the steel hardened adequately.

But I guess if the buyer remains happy...then you might not have screwed them.

-

Sweet looking package, John.

On 2/11/2021 at 3:14 PM, John in Oly, WA said:My latest blade has taken me about 3 years to make.

With the box, hinges and castings, no wonder....

-

On 1/15/2021 at 7:22 AM, HondoWalker said:

Is that a fair price?

If both parties are happy, then I'd say so.

-

How deep does that go? If this is going to go into the scrap bin anyway, I'd cut the billet in half, polish the cut ends, and etch to see how deep the un-welded portion is.

If you didn't grind the sides completely flush before welding the billet together, you will get that on the edges, but it might not be deep enough to worry about.

On 1/17/2021 at 10:10 AM, mpc said:I just kind of assumed it was “done” because... I don’t know why... because it was... cold?

only if the weld was bad enough for scale to have formed between the layers.

-

Depending on the price, it might be worth looking into. Especially for folks who don't like the maintenance of plain carbon steel damascus. Is there any (or plans to look into) food safe information for kitchen cutlery?

There are already other relatively cheap coatings that work plenty well for damascus. GunKote by KG industries comes to mind, and hard to beat $25 for a jar that will last hundreds of blades.....

-

Looks good.

But I'd still make the guy a knife in trade (or thanks) for the cable....

-

On 1/12/2021 at 7:58 AM, Emmi said:

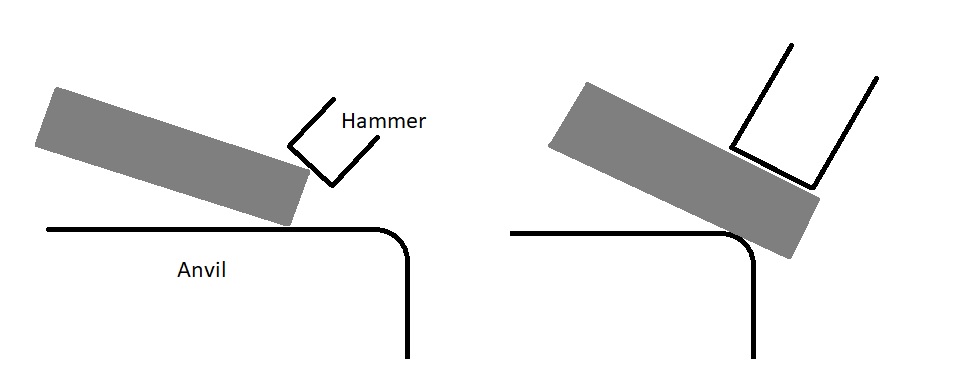

How does one avoid the fish mouth

I'd suggest trying this. A lot of folks do what's in the first picture, but that almost always causes a fish-mouth. By starting the taper as in the second picture, you are going to push metal into the 'fish mouth' and will be able to finish the point without having to cut off any material.

Basically you are setting up the point before finishing it, or as some smiths would say, doing the pre-form first.

-

On 1/6/2021 at 7:45 PM, Bob Brandl said:

Damascus Steel: Theory and Practice, by Gunther Lobach.

I'll second this recommendation.

-

Hi Alan. Sorry I didn't see this earlier (I don't peruse this site much anymore). I'm not exactly sure what you are asking (feel free to redirect me), but I've got a couple thoughts:

First - it took quite a bit of fiddling with the needle valves to get the propane flow set properly for it to work well. And I've had to continue to fiddle with the idle valve occasionally. Secondly - I often close down the air baffle on the blower because I've been doing almost exclusively damascus since I did this modification, which might be why I have had to continue to fiddle with the needle valve more than I should. And (thirdly) now that I think about it, it's been about 3-4 months since I've switched it to auto, because I've been trying to minimize scale formation while forging....

Hopefully that gives you some useful information, but I'm afraid it doesn't.

-

11 hours ago, ThomasPowers said:

I'm sorry but I'm not Glenn

Yep, my bad, sorry 'bout that, Thomas.

2 hours ago, Glenn said:Billy, I realize you were trying to be helpful and do not fault you for that.

Thanks Glenn. And I'm sorry you felt you had to take time out of your day to respond, both here and in the message. I completely understand not wanting this site to turn into a free advertising space, and I appreciate your efforts to maintain that.

So just to be clear, if another offer like this comes up in the future, we're to post something in the tailgate section about "XXXX is advertised in XXXXX craigslist"?

-

Thanks for the words of encouragement, folks, but they were unnecessary. I'm not that easily offended, merely stating the facts.

4 hours ago, Steve Sells said:for some odd reason BIlly thinks IFI needs to pay for him to advertise other people sales?

I'm not sure how you jumped to this assumption, but I'll resist the urge to rant back.

-

Yes, Glenn, it was. Apparently I got a warning and point was deducted, even though I have no financial interest and was merely trying to help folks out....so much for trying to be helpful. This is one of the reasons why I limit my participation on this forum.

-

Just saw this posted on another forum. Someone in need of an anvil should pick this up.

Tampa Craigslist

[Commercial link removed]

-

Not that I remember, but it's possible....I guess

Stay safe

-

No blood, no foul, Frosty.

I was wondering if I missed something as I've been known to word things poorly.

I was wondering if I missed something as I've been known to word things poorly.

-

19 hours ago, matthew stagmer said:

Today I developed a new ladder pattern design for a damascus sword that I am making for Bladeshow (if it happens)

Pics!!!!!

please

-

15 hours ago, Frosty said:

Or give them a call and ask. Have your serial number, date of purchase, etc. at hand of course. If the problem only effected a couple few machines it'd be a real shame to take yours offline while you wait for a notice that'll never come.

Make sense?

Frosty The Lucky.

Of course that makes sense, Frosty. Isn't that what I recommended when I said

On 7/6/2020 at 6:02 PM, billyO said:If you've purchased a Coal Ironworks Press recently, you might want to hold off using it and check to see if your press is affected.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Good evening, all. First, thank you for the compliments, you all are too kind. Here's some quick phone pictures of the finished piece. The last one shows the colors the best

This has been a fun project to do with Jacqueline and I wish I could do more of these. Much more fun than the running of the metal shop....but back to work.