billyO

-

Posts

549 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by billyO

-

-

Welcome Doc! Another suggestion I'll make is to check the date of any topic you reply to. For example, this topic was started almost 10 years ago, so those involved in the original conversation probably aren't paying attention anymore.

Have fun!

-

11 hours ago, Laughing Dog Forge said:

Thanks Billy, Yes I am a member of the NWBA looking forward to the next conference!

If you've been to any of the conferences in the last number of years, you probably know Bear, the picture under my name....

Hopefully I'll be able to make the 40th Anniversary Conference this May, if so, see you then.

-

5x5=25 x5=125 x5=625. makes sense to me.

1 hour ago, Laughing Dog Forge said:I just want to know if there is a way to show off the cable in the pattern,

I'll agree that this many layers won't make a great damascus pattern, even if you were to use the typical 1080/15N20.

I've found that when I get past ~300 layers, the pattern doesn't show up much.

If you have any of the cable left, I'd just twist weld the cable into a billet, cut it into 2 pieces and then sandwich some 1080 or other tool steel for a san mai blade as mentioned above. You still probably won't get much of a dramatic pattern because the 1040 is like a mild steel and not enough nickle to shine.

Here's a pic (not the best, sorry) of one I did with O1 core/15N20/mild steel on the top. Notice how the mild steel looks kinda muddy.

This one is O1/15N20

31 minutes ago, Laughing Dog Forge said:what are your recommended dilution ratios

I use 3 parts water to 1 part Ferric Chloride (PCB etchant from Radio Shack)

You in Portland? Are you a member of the NWBA?

-

Thanks.

-

6 hours ago, ThomasPowers said:

Look at the various LED options out there.

Thanks Thomas, but not sure what you mean. Now that RadioShack is no longer, I'm at a loss.

Any suggestions on how to or where to go to compare brightness? I can't drive anymore due to medical issues, don't live in an urban area and need to find rides into town, so shopping around at different stores is not practical for me.

6 hours ago, dickb said:What is a watermark ?

https://en.wikipedia.org/wiki/Watermark

As an aside, the watermark in question is from Fabriano, where my Grandfather was born. I actually picked it up over 20 years ago before I got into blacksmithing, and it's a watermark of blacksmiths.....I'll post pics when I'm finished.

6 hours ago, Daswulf said:There are many small led battery lights out there. I recently purchased a 5 light set at Sams club that is even remote controlled and the individual lights are pretty small, round and bright with dimming option.

How much did the set cost, Das?

-

Hello all. This isn't specifically blacksmithing related, but it is for a forging project I'm working on.

I'm making a standing frame for a watermark I have and looking for a way to provide the lighting.

I purchased one of these battery powered tea lights off the net and it's not bright enough, so I'm looking for ideas. There's no way that I can see to swap out the bulb for a brighter one.

Thanks.

-

I'll agree with both of the above, but I've also had a failure, so I try to clean the steel as much as possible first. Even if it doesn't matter, I feel the less nasties I burn up in the forge, the time spent doing this isn't wasted.

-

6 hours ago, Cavpilot2k said:

I've also been thinking about attempting a cable damascus. Does anybody on here do that by hand?

The swages do help, but not necessary. At the beginning. go very slowly and strike softly until the steel feels like it's getting compressed into a solid mass and keep twisting the stock like you are trying to tighten the twist as you forge.

-

-

Nice looking knife.

On 12/31/2018 at 3:52 PM, Jclonts82 said:Made a block from a slab of mesquite, had a clever idea. Just after the dark line on the top of the block, i have a strong hidden magnet about 1/8” from the carved channel the blade goes in that holds the edge off the wood when the blade is inserted.

Nice!

I will hopefully remember this on my next one. Thanks for sharing.

-

I hear ya, Maxwell. My brother is expecting -40 in Minnesota....

But to be honest, I'm more concerned about the 95 deg summers with 90% humidity that cools down to 90 deg with 90% humidity at night.

You can always put more clothes on, but only take so much off.

Stay warm and safe.

As always

peace and love

billyO

-

Steve - I grew up in the Chicago area, have lived in Washington for 25 years, and am thinking about moving back to the South Side, like I said.

-

Hmmm...I don't use a press, but do use a #250 chambersburg with big flat dyes and haven't had that happen on the 3 billets I've made yet....

sigh - I guess I have to keep trying..

as always

peace and love

billyO

PS- whereabouts in norther IN are you? I'm from the Chicago area and thinking about moving back to somewhere on the south side

-

I'm still trying to figure out how that happened, so my other thought is...

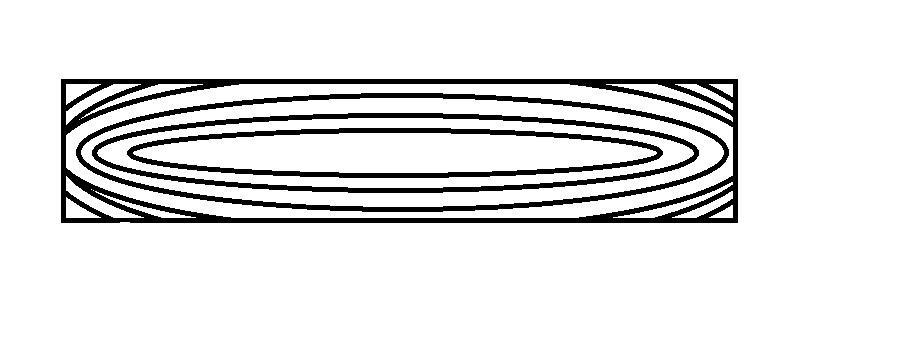

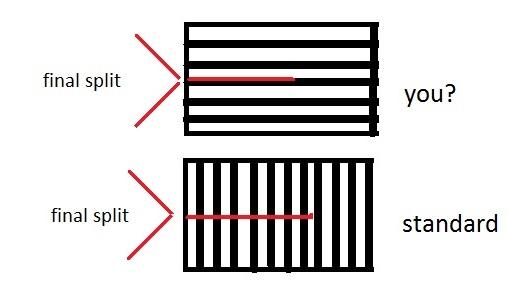

Did you forge this by hand? My guess is yes, and if you've noticed, while drawing out a billet, because of loss of material due to scale top view the bar ends up looking something like this:

So when stacking for the chisel cut, you wouldn't get the exact alignment I showed in the 'standard' above, which could cause what you ended up with.

When using power, there is less loss of material, so it's easier to keep the layers aligned like the 'standard' pattern.

I'd appreciate some input from those smiths who have been doing this longer than I have.

as always

peace and love

billyO

-

7 hours ago, Robg said:

I'm learning through trial and error.

This might not be the most economical way to learn, but IMHO, as long as you're paying attention, the best way.

If just starting out, I'd recommend joining any 'local' blacksmiths organizations. A great way to meet close smiths, get invited to their shops, and learn.

as always

peace and love

billyO

-

Is that sanded/polished or still rough forged? You'll possibly (probably) be able to see the chain better after finishing.

Welcome to the obsession of pattern welding....and have fun.

as always

peace and love

billyO

-

11 hours ago, Robg said:

I'm just wondering why the chainsaw chain came out a muddy mess. No distinct pattern. The blades had some pattern but really light patterning. How do you get the really nice dark etch? Both were soaked about 20 minutes. This is my first time etching so I'm sure it's probably operator error too lol. I did not harden either one of these or take them to a mirror finish either. I just wanted to take a peek lol. Thanks

I'm not sure what you mean by 'muddy mess', but if you're referring to the fact that it doesn't look like a chainsaw, that's due to the all the squishing around from forging.

If you're referring to the pattern not being very dark, there are a couple possibilities (and I'd says it's a combination of all of them). First, the chainsaw chain's links are probably not very high carbon content, even might be mild steel. This is probably the main reason. Second if you only soaked it in the coffee for 20 minutes, that's not long enough. I've left mine in the coffee for 24 hrs without any difficulties other than a bit more to clean off the steel with the nickle content. Third, because there isn't many layers, you won't get much topography with the acid etch, so when you clean/polish the blade, unless you are extremely careful to clean only the 15N20, you can't help removing some of the etch/coffee.

6 hours ago, Frosty said:I think it would've come out nicer with a longer soak in weaker solution.

I'll correct this by saying stronger solution. The coffee won't do any damage to the blade, and actually, doesn't etch for all practical purposes, only darkens the carbon steel. The coffee solution that I use is 1/2 lb of the cheapest instant coffee I could fine to 1/3 gal water. (I read somewhere that someone was going to do a test with different types of coffee, but haven't seen any results.) I've also found that the more I use it, the darker it etches.

I'm not saying the above responses are wrong (well, except for that part of Frosty's

) because remember, if you ask 10 blacksmiths how to do something, you'll get 12 different answers.

) because remember, if you ask 10 blacksmiths how to do something, you'll get 12 different answers.

-

9 hours ago, ThomasPowers said:

You can etch for topography which will stay around longer---however it will also cause issues with cleaning.

On my kitchen knives, I etch to topography, then coffee. How strong was the coffee? The coffee solution I use was a 1/2 pound really cheap instant coffee to 1/3 gallon of water. I've found that the more I use it the darker it makes the pattern. Also, how you clean it will affect the longevity. I wash my knives immediately after use, don't use any scrubbers and then blot dry then air dry before putting away. Wiping the blade will wipe the coffee darkness off.

These aren't the best pictures, but I think you can see the contrast on at least part of the blade. The top one is the first knife I made 3 years ago and the bottome one is 1 1/2 years old. Neither one have been re-etched or re-darkened.

as always

peace and love

billyO

-

I, too, like the look of that pattern. In trying to figure out how you did that, I'm wondering how you cut and stacked the layers before splitting. It looks to me like you stacked them with the layers lined up longitudinally with the blade instead of perpendicular to the blade, which is how the standard feather pattern is done.

as always

peace and love

billyO

-

On 1/7/2019 at 5:45 PM, Zachary said:

That’s the only wood I have that was big enough to do the handle. I’m trying to find some more nicer wood.

I hope this is an OK post, if not, Glenn, Steve, I apologize and feel free to remove. I'm just trying to help out a fellow knife maker.

Zachary, if you really can't find any acceptable handle material, I'd suggest checking out https://www.bladeforums.com/forums/for-sale-knifemaking-supplies-tools.765/

And no, I'm not merely trying to drum up business.

-

20 hours ago, Buzzkill said:

Forging will alter the pattern. There's not much getting around that.

Finding a smith with either a power hammer with big flat dies or a hydraulic press will only make the drops larger, but should keep the round shape.

-

Perhaps you can find a smith who has a rolling mill who'd be willing to reshape the bar?

-

On 12/13/2018 at 8:34 PM, Colorado CJ said:

Man this astrophotography thing is addicting!

You aren't kidding. Are you familiar with the DECaLS Browser at legacysurvey.org/viewer?

There may be some interesting images at RA= 186.7278, Dec= 8.9373. Zoom to 10 arcmin and you'll have a number of galaxies to choose from, including 4 merging towards the top right

Another website you may find useful is zooniverse.org (https://www.zooniverse.org/projects/zookeeper/galaxy-zoo/) where you get b/w pictures of galaxies in low resolution to classify and after you give your classification, you can then get a link to the image in the DECaLS browser that gives better, color images of what it looks like.

-

wow

thank you

Descaling with vinegar?

in Knife Making

Posted

When doing my damascus, I use an angle grinder to remove most of the scale before cutting and stacking, only using the belt grinder to smooth out the pieces. I also do most of mine without flux.

I use vinegar after my final forging of my damascus before grinding. It usually takes a day or so, however.

Like templehound and Steve said, watering the anvil helps and staying on top of the scale with the wire brush as you forge helps a lot.