-

Posts

648 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Frozenforge

-

-

Extech has an infrared thermometer that has an advertised range of -58 to 3992 F +/- 1%. Grainger p/n 4THX6. Pretty expensive though. They also have one that goes to 1832 F for much less.

-

Your anvil should be from 1918, I read the s/n as A166529. The German Trenton anvils were from the late 1800s. The 250 is the weight in lbs or 113 kg.

How it got there? Your guess is as good as mine!

-

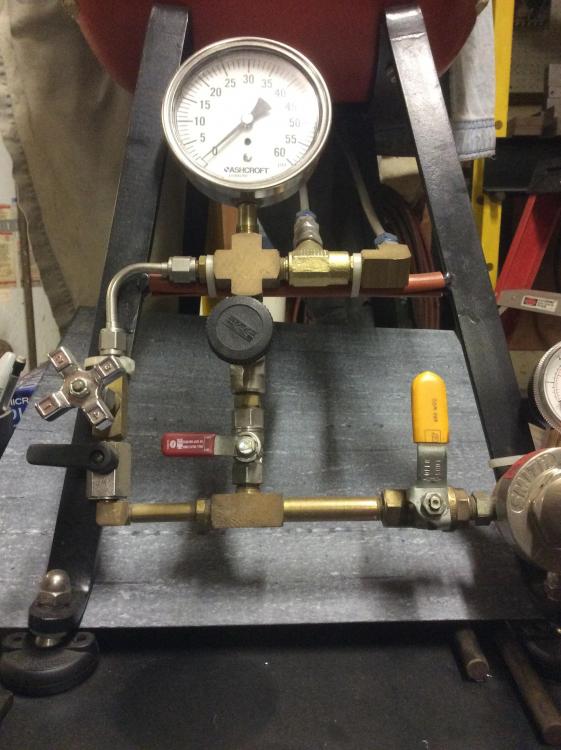

One of the things to remember when talking about all these controls is to have a 2 stage regulator. Otherwise as your bottle cools off from draw and it starts getting low the actual supply pressure drops and a single stage regulator will not maintain a steady pressure. The 2 stage will maintain a constant pressure till the supply pressure approaches the desired regulated pressure.

-

Just a good tip. A little dab of fine valve grinding compound on the screwdriver tip really helps to avoid the cam out effect and prevents the screwdriver tip from becoming polished. Does not make up for an improper tip size though!

-

-

The craft is well represented once again. Thank you!

-

Looks like Trenton as said before. The S/N looks a little strange but I believe about 1912.

-

Only hit hot metal on it and no sledge hammers. Dont be upset if it gets marked up by missed blows. The good thing is you didn’t pay a premium price!

-

When I was a kid back in mid 70s we lived at K.I. Sawyer air force base there in the upper peninsula we would hike over to the rail line and fill our pockets for sling shot ammunition. Hands turned red, pants stained red.

-

Your mig tip appears to be aimed off to one side vs directly down the center of the mixing tube. That might be causing some unwanted turbulence hence the unstable flame. The fine tuning makes all the difference between an OK burner and a good burner.

-

Those scratches are from the coarser grits. You dont notice them until the 1000 grit starts to make it shine. Get a magnifying glass and you will be able to see the 1000 grit marks. Polishing hardened steel by hand is an excercise in patience.

-

As a famous artist used to say “There are no mistakes, just happy accidents”

-

Definitely says 4 . 0 . ? (Single digit). I can make out AND above the 0. Peter Wrights with ENGLAND stamped on them were made after 1910.

The sides were often used to test the hardness of chisels and punches being made.

Its not unusual for the logos and numbers to have been lightly stamped and to have been obliterated over the years.

-

I always remember by the saying “There’s no red port left.”

-

I like to paint one side of my anvil red and the other green so I don’t get confused.

Oh wait which one is starboard?

Oh wait which one is starboard?

-

The S/N 43458 would have been made sometime from 1935 to 1938. No way of knowing who purchased it.

-

The lobes on a normal camshaft are surface hardened to withstand the wear from the pressure of the lifter. As said above unless its a billet steel its just cast iron.

-

Custom fit the brass plate to each hole! Each award would then be unique in its own way!

-

Get a wrench on the flats on the bearing race on the opposite end of the fan and just keep working it with plenty of oil. Either the fan or the race will come off....eventually.

-

Here is the shaft out of the blower minus the conical bearing race right behind the fan. The actual hub with the fan blades is threaded as well. If memory serves me right there are no left hand threads. No point since the blower is non directional. A good penetrating oil, a 3/8 impact wrench and a LITTLE heat on any stuck parts works well. The impact action will help to prevent breaking things.

-

Has a handle on it and it looks to be about 100lbs. Nice score .....21$!! Thats just crazy.

-

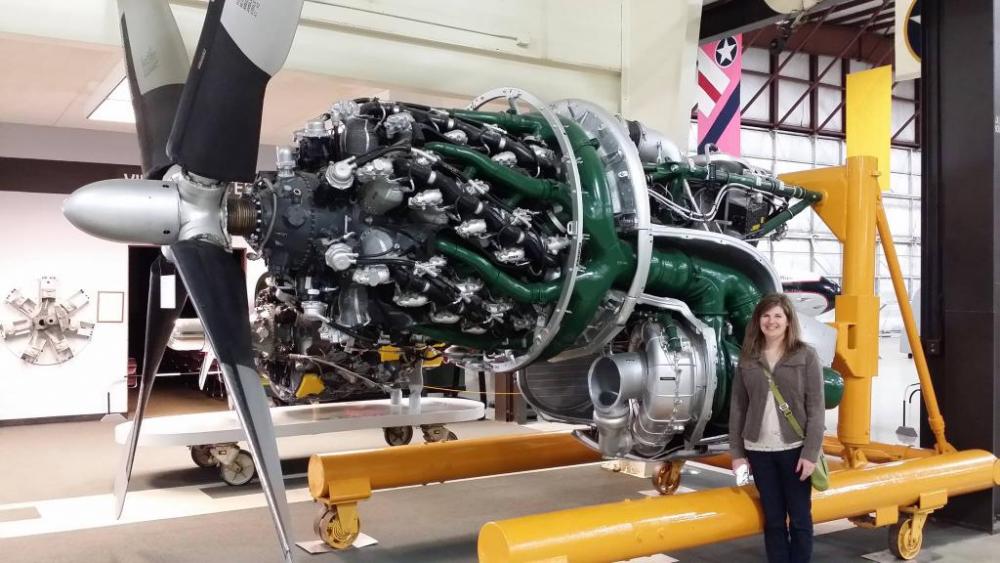

You could access the engines in flight thru a passage in the wings. Each engine had a 100 GALLON oil tank! The people building and maintaining these engines were specialists indeed.

-

The oiler on the old radial engine aircraft would pump oil stored on board into the engine oil tanks to maintain the correct oil level. Sometimes oil consumption was the range limiting factor for the aircraft. Pratt &Whitney R-4360 Quite a piece of mechanical engineering, 28 cylinders 4360 cubic inches of supercharged turbo compound engine.

-

Going from 3/8 round to 7/8x5/8 will take quite a bit more effort! You could get it up to yellow heat to make it easier.

Show me things that move

in Metal Sculpture & Carvings

Posted

Restored a friends family heirloom windvane that was on his grandparents house on Wasilla Lake which sees pretty fierce winds every winter. All he had left was the Eagle and it was falling apart. Runs on bearings and swings to the slightest breeze.