Boyhowdy

Members-

Posts

25 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Boyhowdy

-

-

-

-

- 1 comment

-

- Damascus Knife

- Custom Knife

-

(and 3 more)

Tagged with:

-

- 1 comment

-

- Custom Knife

- Hunting Knife

- (and 8 more)

-

- 4 comments

-

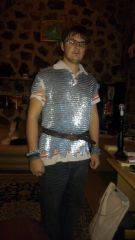

- chainmaille

- haubergeon

-

(and 1 more)

Tagged with:

-

Thanks everyone, I appreciate you input.

-

I would like to get some feedback from anyone who has used rounding hammers. I am going to purchase one, and would like to know, "Is there any difference in the quality..............NORDIC VS. DIAMOND?" Thanks

-

Wayne should be able to take care of you. http://www.waynecoeartistblacksmith.com/

-

Very Nice, indeed

-

Here is a link, This guy has the perfect example of an idle circuit http://traditionaltoolworks.com/smithy/forge_build/index.html

-

Right now at the coop near me I can get my 20 lb tanks filled for $14.25. At the exchange they are $22.00. That's quite a savings. As far as how long a tank will last a single burner forge will use (approx) 1 lb per hour @ 3 psi., 2 lbs an hour @ 6 psi, and so on..... Another thing that will make a difference in fuel usage is the type of insulation in the forge. Any gas forge should have a Reflective coating in it,(plistex,Metrikote,ITC 100 HT) if not get some. it makes all the difference in the world. I just finished building a (single burner) gas forge, and cannot believe how well it works. I get a hell of a lot more heat from that single burner, than I ever did with the 3 burner, which will now be getting a Metrikote treatment.

-

According to his website he will be closed for a couple months, due to medical problems. He does have quite a selection of parts. Thanks

-

Wayne, I did check out your website.......Impressive....I have it bookmarked......I will definately contact you when I'm ready to order some materials. Thanks again.

-

Thanks again guys.......Rich, sorry 'bout that..... I wasn't in the mood to put up with their crap last night. Like I said in the earlier post, Every bit of info really helps.

-

Thanks Guys. Every bit of info helps.

-

Here is a question I asked in the Iforge chat, and Just got a bunch of jokers trying to be funny. I have a three burner Propane Forge that uses way too much fuel for my pocketbook. I am building a smaller single burner, and would like to know: "Which is better to line it with, Soft, or Hard Bricks?" I have hard brick in my current forge, and I feel the bricks are absorbing alot of the heat. Any suggestions would be greatly appreciated. Thanks

-

Yes it is. VERY Happy with it.

-

After doing some serious inspection, and a little more digging, I found out it is a 125# Yost circa 1924...Made in Meadville PA.

-

I purchased an Anvil last thursday. I was hesitating on the Purchase because I wasn't sure whether it had a good ring, or rebound to it. The guy that had it dropped a 1" Ball Bearing on the face, and that sold it instantly, as there was about a 90-95% rebound. He had it advertised as a 120lb Kohlswa, but upon getting it home, and inspecting it further, I don't know how he figured it was a Kohlswa. The only Markings I can see are difficult to make out. On the side with the Horn Facing to the LEFT there is a FAINT marking that looks like Possibly, (UST), or (JST), and below that is what appears to be a a city name, that is difficult to make out as well... It appears to be on the lines of (M----VILLE). I have done a search and have come up with nothing. I haven't remove the Anvil from the stand to see if there are any markings on the bottom. I am attaching the Only pic I have at this time. My camera took a Dump on me this weekend, I will post more pics when I get a new camera if needed. Thanks in advance.

-

Dumb question about normalising

Boyhowdy replied to Rob Browne's topic in Heat Treating, general discussion

Normalizing is a type of heat treatment applicable to ferrous metals only. It differs from annealing in that the metal is heated to a higher temperature and then removed from the furnace for air cooling.