-

Posts

1,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SReynolds

-

helpfull input wanted for scrap steel coal forge

SReynolds replied to Dustin Taylor's topic in Solid Fuel Forges

I love brake drums. I have several as I keep them for just such a job. I work on heavy truck when not teaching and they are super for an anvil stump base, mounting a leg vise or grider etc. Some are 12" deep overall. VERY HEAVY AND SOLID The firepot would do well if you grab a truck brake drum from a pickup. About 3 to 4 inches deep. Them a pipe flange bolted to bottom then pipe coupling to a T then more pipe below that to hold ash and clinker bits. I cant say how deep but four inches would be good. Some folks want a shallow fire and others a deep fire. I use a large brick and stone forge and it's eight inches deep. I love it. Works well for me for coal. I did the same. Opened up my ash dump about half way to assist regulation of air. But my use of hair dryer was temporary. I like the old blowers -

Is a $140 hammer really that much better than a $40 hammer?

SReynolds replied to Pancho07's topic in Hand Hammers

I agree. I did same. -

Is a $140 hammer really that much better than a $40 hammer?

SReynolds replied to Pancho07's topic in Hand Hammers

Thusly I said "interesting" and "Just saying" You wouldn't have seen mine. It didn't last very long. But my point was "they" have hammers of the "such and such" style for "x" amount of money. -

Cruise through the scrap yard Pic Heavy

SReynolds replied to natenaaron's topic in Blacksmithing, General Discussion

That is how I purchase stock and it is real cheap too and free delivery. But they charge extra if you want it cut to length. The more elaborate stuff as in alloy is purchased in a smaller amount per foot. -

Is a $140 hammer really that much better than a $40 hammer?

SReynolds replied to Pancho07's topic in Hand Hammers

I did the very same thing; Brand X found on the such and such web site. I was notified three times and post removed. We see a big difference between answering posted questions, and a person just randomly posting adverts for other places. If we were at Thomas Powers shop for a class, and used his gathering to inform others about another class at another place, it may or may not offend Thomas, depending on content one should not be surprised to find he is upset you sent his clients to other places. Internet hosting costs money and many of these other places have had the opportunity to be apart of IFI some have paid to advertise here, others refused. Why would the forums sponsors want to keep paying to help us stay online when members give it away for free to their competition? -

Cruise through the scrap yard Pic Heavy

SReynolds replied to natenaaron's topic in Blacksmithing, General Discussion

One other locate I see it and buy from time to time is a local machine/welding/fabrication shop. -

Cruise through the scrap yard Pic Heavy

SReynolds replied to natenaaron's topic in Blacksmithing, General Discussion

can you locate a farrier supply near with a rack of ready to go stock as pictured?> A home Depot? A Lowes? Even a True Value hardware store? They have steel stock. The best is a steel supplier. They welcome public sales. The local scrap yard don't let folks wonder about picking out steel. You can drop off but not pick up. I don't know your individual situation but it isn't difficult to locate. I mean simple steel stock such as rounds, squares and flats. -

-

LOL True that!

-

helpfull input wanted for scrap steel coal forge

SReynolds replied to Dustin Taylor's topic in Solid Fuel Forges

Less air. Cut the air flow back. A hair dryer on low setting is a load of air. It will work fine if you can vary the air flow via a gate or rheostat like a singer sewing machine treadle or household dimmer switch. I slipped in a hair dryer into a coal forge, in place of the old champion hand crank blower and it was a HUGE amount of air flow. You could always employ a squirrel fan cage blower or just about anything. Even an old hand crank blower mounted to forge or a stand alone. Love the video. You weld really quickly and I like how it gets dark. How'd you do that? LOL -

I don't know if I'm allow to say per forum rules. I have been burned by doing so in past. PM me if you'd like.

-

No prices are on the tags. You give tag numbers to clerk and the clerk's assistant looks it up. Yes they deal with you in price. A smile goes a long way. Walk in smoking a cigarette and cursing won't save you money. I have traded a number of items for other tools as well. But you loose money doing that. Obviously. There is coal as well as shoes and nails and tongs etc. You know.......Farrier type stuff. Anvils are a solid 4.00/pound if not more.

-

This is a series of pics of the local Farrier Supply. They carry new as well as used. Some pics of a few of the used tools, forges, anvils, vises, blowers, steel stock etc.etc.etc.

-

-

Is a $140 hammer really that much better than a $40 hammer?

SReynolds replied to Pancho07's topic in Hand Hammers

Interesting in that you mentioned the website name/tool and price. Just saying. -

School me on Hardy hole size.

SReynolds replied to Thats Hot...'s topic in Anvils, Swage Blocks, and Mandrels

If made properly they won't rock. Yes, there is a very small contact area in relation to a hardie and the anvil, but remember this is a cutter. Not a fuller or a swage. I didn't mean to give impression that I make many tools with a tapered wedge fit. Only the hardie cut. -

Well. . . .yes, but I wasn't going to go there. Or possibly a lawn tractor name brand. John Deere isn't good enough these days. If you really want to cut that grass you need a; Ranch King Lawn Chief Master Mower Turf Titan Pro-Cut Simply the name alone invokes professionalism. I doubt blacksmithing is different, eh?

-

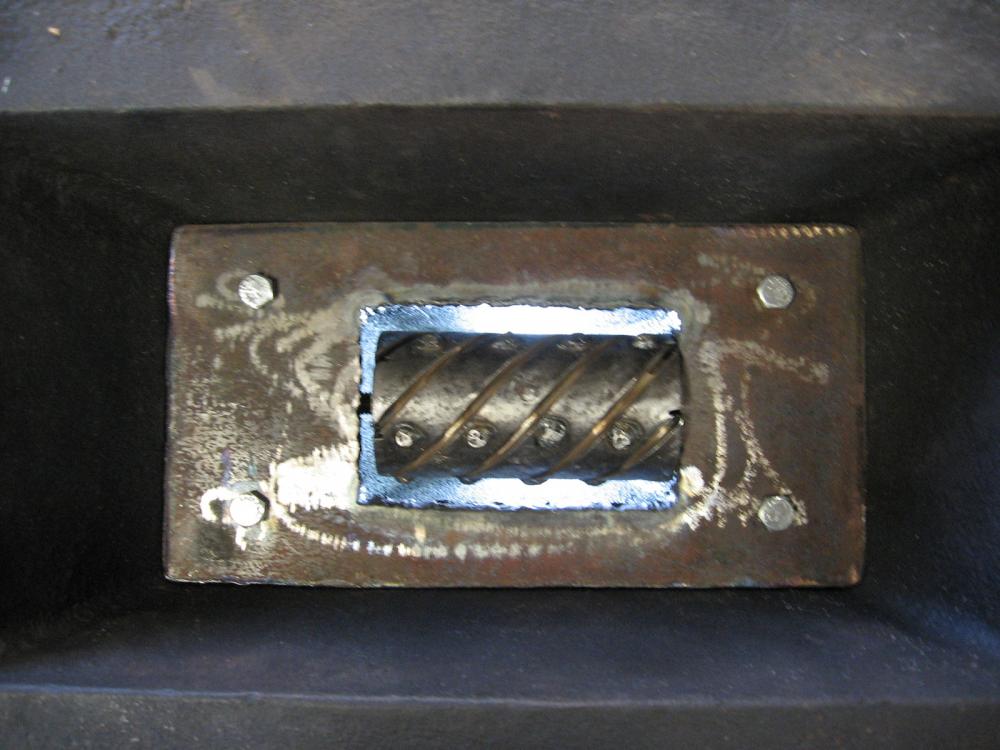

Guillotine Fuller with various bits. Homebuilt. Folks see it and ask me to make one. It sets atop the hardie hole. It is 4"x4" throat w/spring steel bits. If you dont have a one man guillotine what are you doing to fuller items by your lonesome? a spring fuller? The 4x4 size takes place of dozens of spring fullers. I wont bother to take a picture tonight.

-

I took a number of pictures of a forge I found this weekend. It has three slots in firepot (tuyere) 3/8" wide by 2.75" long. What blows me away is the clinker breaker. It has a cast iron wedge that is located about 1-1/4" below the air slots. Think about that and form a mental picture. Some company designed and manufactures these. What's the point? Is the clinker 1-1/4" BELOW the firepot? I see another popular breaker is a slotted nozzle that rotates side to side. Ok. So . . . . .tell me what cleans out the slag/clinker from THE SLOTTED HOLES where the the air passes? This is my own design. A 2 and sone inch solid steel cylinder that rotates inside of a hole. It destroys slag and clinker cuz the air passes s between the sides of cylinder and o.d. of the hole. The knobs welded to the cylinder chew up anything you place near it. Maks sense to me. I use a champion firepot with clinker breaker at a historic village and guess what. I have to use a 1/4"steel rod forced down into the air slots to break up the clinker etc to revive the air flow. . .

-

I guess so. If something is professional grade; and yous buys it. . . . . . LOL!

-

So if cast iron contains more carbon why oh why is it so easy to drill/tap etc? I would tend to think it would be very very hard. When you have 1020 it isn't so hard but say a 51100 is. So add more carbon like 3.00 % it softens up. How come?

-

EBay sellers are now offering for public sale professional grade cast iron anvils. Are they much better than the non-professional grade cast iron? Sounds like these could possibly be quite the bargain. I want to get mine early on before the cat is out if the bag on these and inventory is depleted. Now I can become that professional blacksmith my mother had always hoped for me.

-

Cruise through the scrap yard Pic Heavy

SReynolds replied to natenaaron's topic in Blacksmithing, General Discussion

I'll take a second look but didnt see anything you could use; easily. The coil spring is popular with some; If you desire to uncoil it and NEED that size and type of stock. I'd like a couple of the rail car wheels. I could heat them up and make fullers and swages. . . . . . R-I-G-H-T -

Is a $140 hammer really that much better than a $40 hammer?

SReynolds replied to Pancho07's topic in Hand Hammers

One half of this hobby would be the tools. I enjoy all the tools as much as hammering iron/steel. Rebuilding old forges and blowers. Buying and modifying tools. Making my own tools. And I love hammers. All the shapes/weights etc. I enjoy the challenge replacing the old handles with new. Some times modifying the handle grip. The challenge of a tight and reliable fitment of handle to head. Most of these if not all were cheap and/or free. Modified in more than one way. A few I pulled off the bench. . . . -

I temporarily installed a hair dryer on one of my forges (coal) and on low setting it was a ton of air. It was quiet and worked well save for all that air. White hot fire in short order. almost four inches deep firepot and rectangular in shape. Sloping sides. I'd want to invest in reostate such as a sewing machine treddle or household dimmer switch. But I'm not thinking of giving up any of my old forge blowers. It was nice to walk away and still have the fire growing in strength after I constructed it. Something I don't do with hand crank forge blower. And welding two pieces together would be a little easier as both hands are free to manipulate.