-

Posts

564 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by yves

-

Designing a good journal template for projects

yves replied to Jo_Bai's topic in Blacksmithing, General Discussion

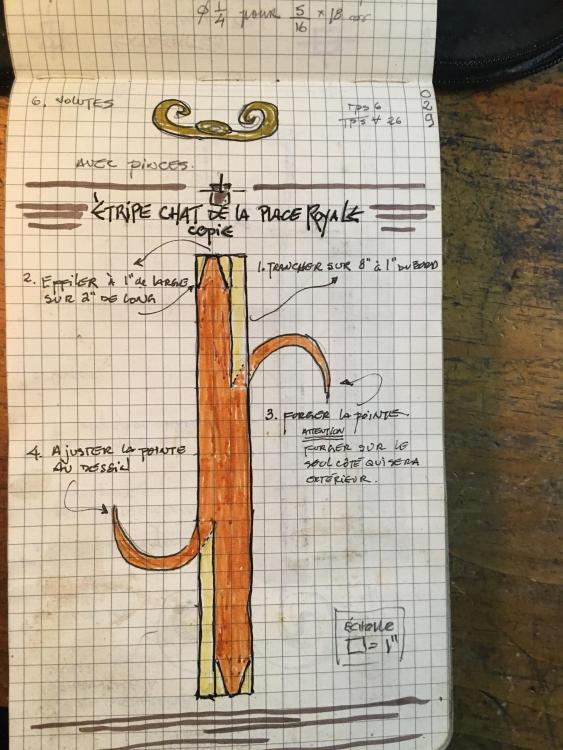

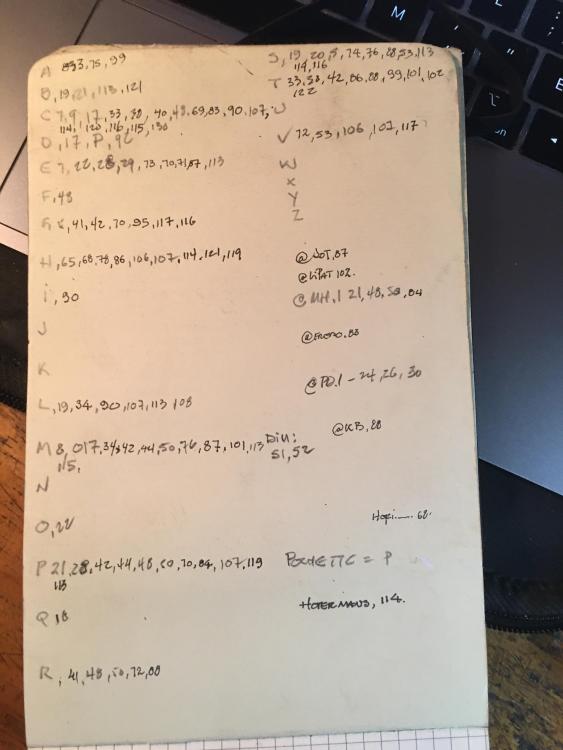

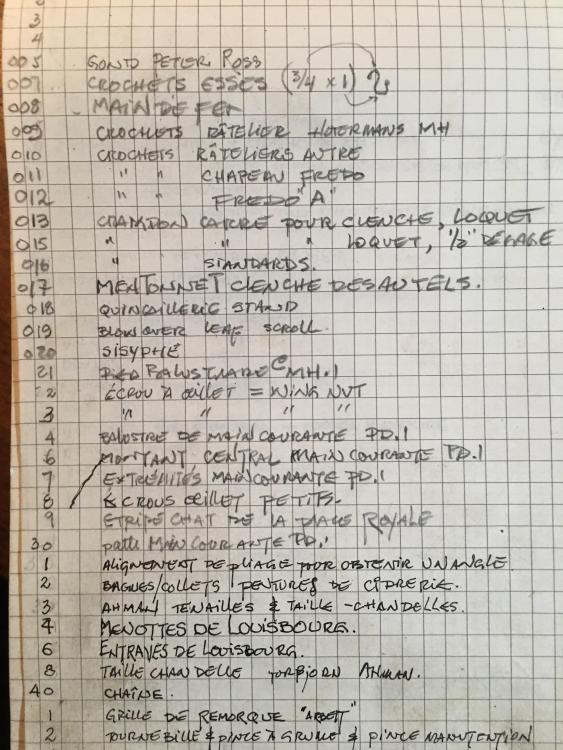

As much as I can, which means when I think of it, I put drawings and notes in a book. When I have to find these notes, that drawing, I go to the alphabet page with page numbers on the lkast page of the book. This one : In this example, the name of what I am looking for starts with an E, so I go at the lettre E and go down the page numbers read what is in this index starting with an E and on page 29 of this page I read "Étripe chat etc. " On page 29, I find what I was looking for : And if I have to add something, notes of pics, I stick them in the book and on the original page ( page 029 in this case ) I write down the page where I will find addendums. For me this is very flexible and being the way I am, I do not loose these notes -

Show me your sales or demo booth

yves replied to Glenn's topic in The Business Side of Blacksmithing

Maybe was I not patient enough, but after six months or so I quit Etsy. I never got any enquiry let alone a sale. I offered mainly fire pokers, various tripods to hold pots over a fire and reproductions of 17th and 18th century utensils including candle holders. Maybe I was too expensive, and I think I was when I compared my prices with those asked by companies targeting the live history people, but I would rather keep my stuff than give away my working hours. I offered the same material that I sold otherwise. My reproductions have been commissioned, for instance, by a TV series. -

You are right. By the way I just saw a guy doing exactly what you describe. As for mine, I have already used it for what I needed and I had enough torque. Thanks. And you are right a hammer blow on hot iron is creative in itself when we are searching, exploring.

- 9 replies

-

- coil spring

- tooling

-

(and 1 more)

Tagged with:

-

As you can see in the pic, I swaged a shape in order to have a grip. At first I thought of flattening the material, punch holes and rivet wood sides for a handle. And then I multiplied time constraints with the possibility of making a screwdriver that did not look like the screwdrivers I know, and that is what I got. I'll see today, I might have some filing to do and then a wax mixture.

- 9 replies

-

- coil spring

- tooling

-

(and 1 more)

Tagged with:

-

I am not a great tool maker. I only forge tongs when I really need them. This one I enjoyed, took my time.

- 9 replies

-

- coil spring

- tooling

-

(and 1 more)

Tagged with:

-

- 9 replies

-

- coil spring

- tooling

-

(and 1 more)

Tagged with:

-

I do not know yet. Still in design process. Neil, thank you for the input.

-

George, I have been on their site. They do not have the dimensions I am looking for. They have a ¾" Ø steel ball but only with a hole half thru. I thank you (1) for the info and (2)… you got me thinking… I might think of using cubes instead of balls. I'll try this when I get to the forge.

-

Thomas, Thanks. I have a project I will tackle after firewood season, a balustrade and I would like to use some steel balls in the joinery.

-

I am looking for mild steel drilled balls Ø3/4", with a smooth hole (not threaded) Ø3/8". I live in Québec. I traveled the Internet and only found some (I think) in exotic places. Anything in Canada, in the US some of you would know about? Thanks.

-

I liked it so much that I wore it for 30 years. It has now acquired the status of vintage.

-

I am glad you bring it up. When I decided to forge, the silo appeared in our conversations. I remember clearly when The Woman saying "Why not in the silo?". It is a great building, plum after all these years, straight as an arrow and just sitting there, empty, useless. And there we went. We sort of saved it. Absolutely no regrets and even though it is only Ø14' (154 sq ft), I have made some longish handrails.

-

Frosty, Grand Daughter has become at 13 years old a Grand Soccer player. She trains and plays 5 times per week and she is taking courses to become a referee. I dropped down on the to-do list. And I live in the country, an hour away. There were also the restrictions with Covid. When the picture was taken, she would come and hit hot metal. It was impressive. She was good. She is an artist. Her uncle will inherit this chimney. This forge hood is interesting not only because the system draws so well but also because there is nothing above the fire pot. It eases the handling of longer pieces. Do not hesitate in your new space. This supper sucker is a good way to go. The sleeve running at the last 4 feet permits to avoid a cap on the chimney. Rain always falling at an angle, hits the inside of the sleeve and runs down to the ground. I have very little water, even very little snow in there. There is a ceiling at ten feet. I can stand 20' bars cut in half. The rest of the silo is empty for now. The son thinks/dreams of installing a film editing studio in there. We have kicked a few ideas around. It would be possible, but the plans are still at the dream stage. Think about it: it would be lovely to raise the aluminium top of the silo and lay it back down on a piece of some sort of glass running all around the top edge or only half and letting only the northern light come in. Possibilities are endless (forged stairs outside with doors at three levels, simple strap elevator in the part where they used to climb to work on the grain).

-

-

This has always been my set up. It draws very well and I never had a problem in winter. In fact, in the picture, you can see how I instruct my grand-daughter to hold on to the handle so that she would not go up the chimney… Single. Notice the top of the chimney where a sleeve (Ø 14") overlaps the chimney (Ø 12") for 3 feet and extends 1 foot over the top. I will take a picture of the inside this morn and will post.

-

Had a galvanized chimney for the last 12 years. It rot away. Had this one installed last Saturday: all stainless steel. It will outlive me.

-

Daniel Moss Candlestick Challenge video

yves replied to jlpservicesinc's topic in Blacksmithing, General Discussion

This is the one I had made 20 years ago (I did not own a welder at that time). As it is set up with a bar on the end, I pile small (6 inches and less) four feet long pieces and bring them to where I cut them in fire wood. To haul long logs (larger diameters), the rear part slides out the tubing and permits to back the trailer over the logs. This is the rear part: In the following pic, you see the chain that would be around a log and it is anchored up front to prevent back and forth movement of the log when hauling and braking. If I want to lift higher, I do not use the large ring. This ring with its chain hook I use on the hitch (ball) on my ATV: I throw it on the ball and hook a chain when I have to haul wood out and take it to the trailer. I have been and still am very happy with this set up to harvest fire wood. -

Daniel Moss Candlestick Challenge video

yves replied to jlpservicesinc's topic in Blacksmithing, General Discussion

Jennifer, Being hopelessly 'mechanically challenged', your competence amazes me. I worry about the chain on your chainsaw when you will cut the wood that has been dragged on the ground. Is there not a way (you could come up with one) to lift the log so that only the end drags on the ground. I have made a trailer (inverted U shape) I back up on the logs, lift them with a chain block and can then drag hefty logs with my 4 wheel Honda bike. Only the end of the log drags on the ground. -

Thanks. It was somewhat tricky to keep everything square.

-

Waiting for the client to pick up. He installs. Some fabrication: help from Mr. Miller for the structural collars, those linking the scrolls to the ¾" structure.

-

Scrap Yard Won't Sell Scrap Metal!!!!

yves replied to CurlyGeorge's topic in Blacksmithing, General Discussion

My coil springs come from the garage up the road where I get my car serviced. He keeps them for me when I ask him. -

Does the regulation in your area permit one to purse an artistic activity? You are [or learning to become] an artist blacksmith. You explore your art for art's sake. It is not watercolour, grant them that, but it is an artistic pursuit. Your building is a studio, not a "commercial building". I would also check if you would be allowed to sell watercolours you would paint in that studio… Good luck.

-

Measuring tools every day. I am particularly attached to my Starrett combination square and every time I use it I wonder why such a precise tool to make something with repeated hammer blows… Most used measuring tools include a gauge I made to measure steel bars and thicknesses of items I am forging. The gauge also is used as a ruler when forging, the inches being "center punched" on it. I must mention that my anvil is also a great measuring tool: 2" to the hardy hole, 5" across the anvil, etc.. Drawing implements are used every day. Most of my drawings are done in 9x12 sketchbooks.

-

Thomas Powers, I do take note of that. Such a pattern could very well decorate a wooden door (one strip running along the center) in one of our farm buildings. It could also make interesting (false) hinges. It probably has been done mind you.