MG-42

Members-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by MG-42

-

I like that vise

-

i have anvil envy

-

building a mechanical forging hammer

MG-42 replied to MG-42's topic in Power Hammers, Treadle Hammers, Olivers

no. it is filled with rebar, sand and lead. -

building a mechanical forging hammer

MG-42 posted a topic in Power Hammers, Treadle Hammers, Olivers

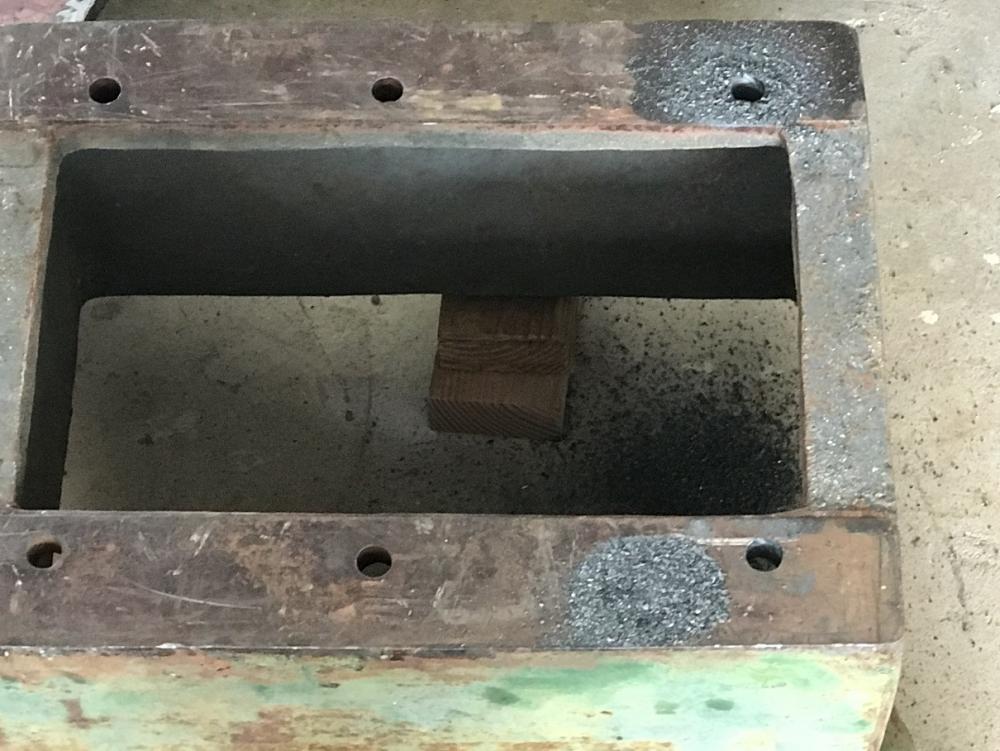

This is a run down on building my forging hammer and my neighbors forging hammer. Not much was bought for this project, most came from our scrap piles. Cutting the steel for the anvil. Cutting the steel for the column. The anvil columns welded to the bases. My beautiful and charming life long love helping me out. Supports for the anvil and column. Basic hammer platform welded up. You can see the pillow bearings and spring attachment Y Cutting the steel for the hammer. A close up of the off set wheel. This was a cut off from a flat plate. a quick shot of the hammer control motor peddle. A number of pictures of the hammer The bearing surface area machined Main column support I have a video of it in operation coming soon. -

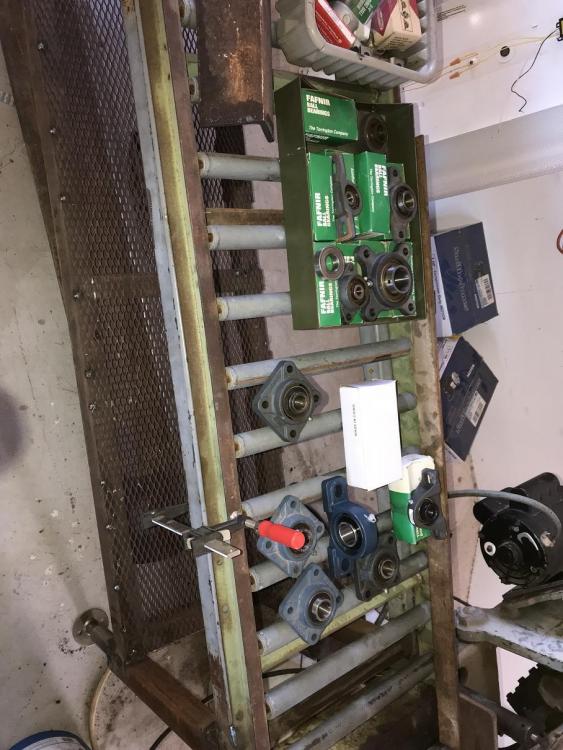

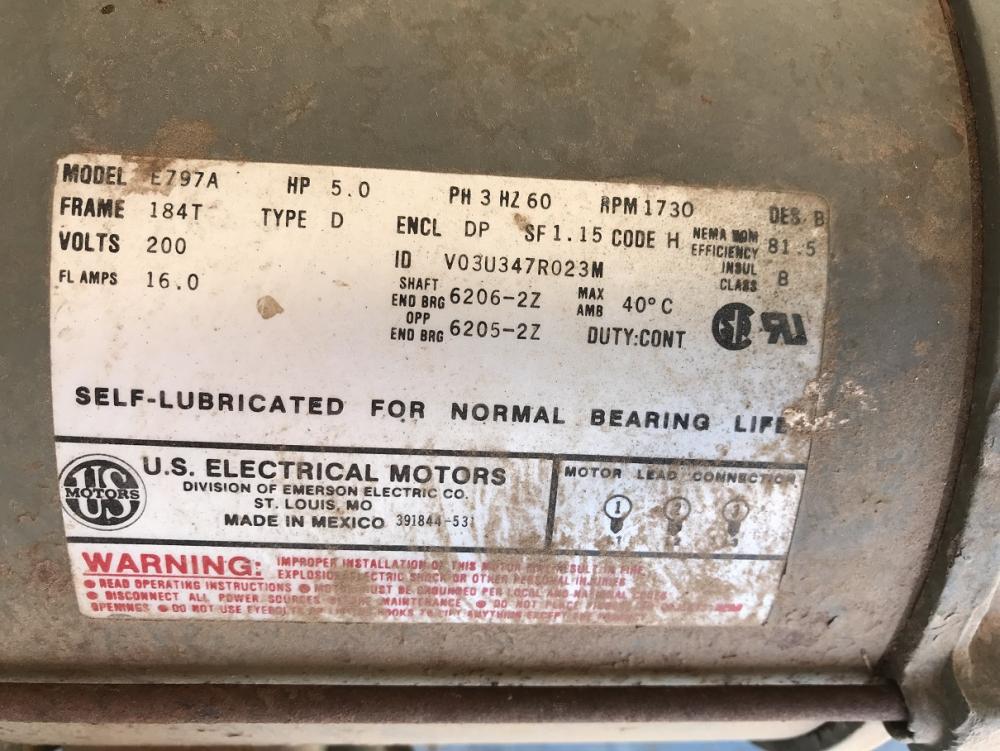

I have started gathering materials for this build. Currently I am trying to do this project with what is available in my scrap pile. I have cut and ground the up-right pieces and the base for the roller After cutting, grinding and milling this is what they now look like. After looking through my shop I actually found a 40 to 1 reducer. In the bearing cabinet I came across a set on 1 1/4 inch bearing that will work for the main roller. I also hit the neighbors supply of junk and he had a set of Harley sprockets and I had the chain to go with them. I am not sure if I need this extra reduction or not. In the scrap pile was also the material for the base. On the saw and being cut to size. going to the motor storage area I found a 5hp 3 phase motor. The funny thing is that I just got a call from a friend that had a 7.5 hp rated VFD. I think that I am on the way now.

-

nice find and the compressor does look new.

-

I am currently working on a Hugh McDonald hot meta l roller. With that said my neighbor gave me this today. Now if you are wondering what it is then let me do away with the mystery. It is a home made horse walker. Just look at the pully wheel and chain and sprockets. This is the missing link to my hot metal roller.

-

beautiful work.

-

I have looked at all the posts on this forum concerning the Hugh McDonald rolling mill and most of the pictures have disappeared. I was hoping to start a new thread with the possibility of chatting with people that have built one to ask questions and see pictures. I have Mr. McDonald's book and have been going over it. I will soon be doing a solid model of his design.

-

Early this summer my wife started a project of organizing all my scrap metal. This was accomplished for 2 reasons. First to clean up all the piles of metal around the property and second to minimize buying material that we already had. It also had a third unexpected accomplishment and that is for me to complete and finish more projects. Here are a few pictures and a video of the yard. You can see the video here.

-

Wow nice anvils. Wish I had the problem of people dropping off anvils at my place.

-

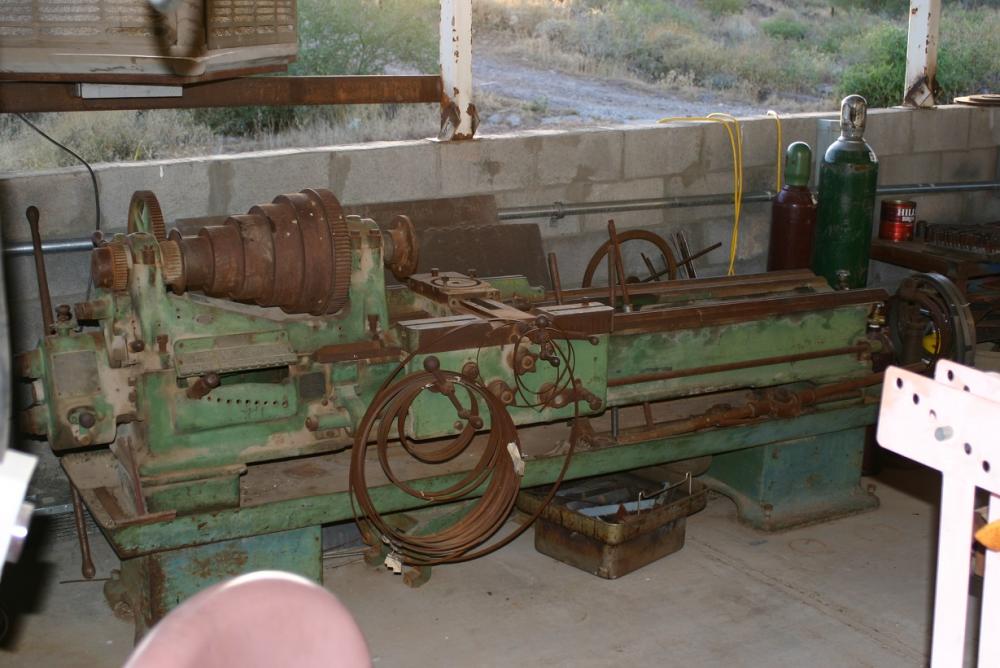

This is kind of it followed me home and then I built something with it post. I am not sure if it should go here or else where.. The story starts with the old lathe I found if an empty lot. The lathe was way past it's life so I took anything of value off of it and scrapped the rest. This is where the stand came from. A could of more holes were drilled. Then a plate from the hydraulic forging press that was cut out of the center was cut to size. combining with the old steel plate from the hydraulic power pack. It was machined to the fly press requirements. The top and bottom plates were welded to a piece of 6" pipe that I dug out of a dumpster. So this is the end result of using all the it followed me home stuff so I can use my 25.00 yard sale find fly press. It now sets next to my forging hammer I built from stuff that followed me.

-

I always look for old and odd bits of metal when I am out. My wife thinks I am nuts but lives with it after 37 years

-

All the hammer heads I have picked up from abandon properties, on the side of the road and out of dumpsters Now I just need to make handles for all of them

-

I did a job at a house and shop that was to be demoed.Asked the superintendent if I could look through the old buildings before the backhoe showed up. Managed to find a few items.

-

Not sure if I should post this here or in some other area. (Mod note: moved to its own topic) This is my saga of building a forge or an extended post of it followed me home. A while back I had the urge to build a forge for my little shop. After hunting through the internet I found plans and ideas for building one from a refrigerant tank. I was given a number of empty refrigerant cylinders and went about making one I made the burner in the machine shop. And made a stand for it as well. This seem to bring about telling the universe that I needed forges. Before I could even finish my home made forge This monster showed up. I was doing some work at a school and they were getting rid of there shop forge and foundry. This was being hauled out to the dumpster when I had them take it to my truck instead. It is set up for natural gas instead of propane so the next step was to do a conversion on it. I obtain the manual and was setting up to buy all the necessary materials when the universe stepped in again. This 3 burner home made forge came about. With this forge I just needed to upgrade the insulation and I was ready to rock and roll. Then this cute single burner forge came up and followed me home. Finally the one I just posted about ended up at my home. What I really need to do is to convince the universe to shift to anvils. If this post needs to go to a different section please move it. Thanks for reading my story.

-

Not sure if it works yet or not. This will be the 4th forge to show up at the house since I started building mine. Stop working on mine as there is now no space for it. I just wish I was an anvil magnet as I am for forges.

-

-

In the last couple of weeks a lot of stuff has followed me home. Starting with this coining press that I found of 25.00. Granted it is not a big boy fly press but for the price I could not say no. Next at one of the lumber yards I do work at I got these from the dumpster, with there permission, Chain saw blades that were used. All together about 60 of them.

-

Wow divermike I love that shop

-

You might be addicted to blacksmithing if you...

MG-42 replied to divermike's topic in Blacksmithing, General Discussion

I just built a locking hammer rack to keep people away from my hammers -

Thanks for the reply's. I actually looked for anvil repair before I posted, just did not look in the correct spot. Thanks again

-

A few years ago I got my anvil out of a dumpster. It came from a school that dropped its metal class. The kits had beat it up fairly bad. I want to weld up the edges and re-grind the face. What kind of rod should I use and what kind of pre-heat.

-

What weird animals have been in your shop

MG-42 replied to Glenn's topic in Blacksmithing, General Discussion

A couple of rattle snakes, bob cat, javelin, and an owl that took up residence for a while. -

I really like you design. What mess?