stickermigtigger

Members-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by stickermigtigger

-

How to dull a hoof rasp?

stickermigtigger replied to stickermigtigger's topic in Farriers and Horse stuff

hot rasp -

How to dull a hoof rasp?

stickermigtigger replied to stickermigtigger's topic in Farriers and Horse stuff

Thanks Daswulf. Amazon has an 18" for $15. I didn't notice coarse grades for hoof rasps. I thought they were all the same. Duh! Used ones on FB are more plus shipping so expense isn't really an issue. Maybe I can do it like we used to do blue jeans and drag it down a gravel road a ways. :-) -

How to dull a hoof rasp?

stickermigtigger replied to stickermigtigger's topic in Farriers and Horse stuff

I did consider that and it might work. My thought is they're so sharp to start with they'd do a lot of gouging on hot steel before they wore to whatever is an appropriate 'dullness'. I think a sharp rasp would also be pretty difficult to push against steel. Ultimately I have no idea. Your thought is as valid as any other. -

Yes I know I can hunt down a farrier and find used ones. Yes I know you can find them on FaceBook and pay shipping. Neither of these is efficient. Plus I can buy an 18" hoof rasp on Amazon for around $15 with free shipping. (Yes, probably Chinese made. Don't care.) My question is what would be a good way to dull a hoof rasp so that it is useable when forging? I can think of a number of ways, some draconian, some labor intensive, etc. I'd like to how you would go about dulling a hoof rasp to suit your forging needs.

-

B&W and DTX anvils

stickermigtigger replied to Chaz7795's topic in Anvils, Swage Blocks, and Mandrels

"I don't have any experience with them" either but I've got a 1939 Ford with a wiring problem you might help me with. -

I need to replace my oil reservoir sight glass. Got cracked somehow and is slow weeping oil on the machine and the floor. The thread with mics to 32mm/1.25”. I don’t know what the thread pattern is but I’m sure it’s metric. About 13 to the inch but that’s a guess. Anyone know from experience with these hammers what specs to order?

-

Say Mak ? Info Needed

stickermigtigger replied to ironwolfforgeca's topic in Power Hammers, Treadle Hammers, Olivers

Have the SSM-50 as well. You've probably found a manual by now but if not I have one I'll share. If you have any links or know of user groups, or technical spec sites from this machine please share. -

Just ignore him Roy. He's always looking for a fight and an opportunity to belittle someone.

-

I have a new to me 2002 Say-Ha SSM-50. Amperage under load is used to judge belt tightness on this type of machine (Say-Mak, Say-Ha, Kuhn, Sahliner, etc.) The newer Say-Maks are the descendent of the Say-Ha and it's documented that 22.5 amps is the optimal amperage under load relative the tightness of the belt. I cannot find documentation or confirmation (it's not in my Say-Ha manual) that the Say-Ha shares this same amperage parameter as the Say-Mak. Can anyone confirm or link to documentation that can answer my question? QUESTION: Is the optimal amperage on the Say-Ha SSM-50, 22.5 amps? (In this thread/context I don't care about anything other than that amperage parameter.)

-

SayMak SayHa Dies the Same?

stickermigtigger replied to stickermigtigger's topic in Power Hammers, Treadle Hammers, Olivers

[Inappropriate language removed] I looked all over that site. Even downloaded and am watching the DVD set. thanks Larry! -

The SayMak is a descendent of the SayHa. I did query the current Say-Mak dealer but haven’t heard back. I have a suspicion garnered from Googling this topic that the Sahlinger and SayMak can swap dies as well as some other similar brands. Anyone know for certain that Say-Mak Say-Ha hammers have interchangeable dies? saymak sayha

-

Muffler for Self Contained PH

stickermigtigger replied to stickermigtigger's topic in Power Hammers, Treadle Hammers, Olivers

Ha! Just found dozens of air compressor intake and exhaust filters on Amazon and Google so i think i got this figured out now. Thanks folks. -

Muffler for Self Contained PH

stickermigtigger replied to stickermigtigger's topic in Power Hammers, Treadle Hammers, Olivers

Good point and I'm in the same boat; I don't know. All the SayHa I've seen (4 :-)) and the one I now own had mufflers on them. That's all I've got to go on. No intention of blocking the exhaust; would never cross my mind. I hadn't thought of coll/sep though so I'll look into that although I'm going to vent to the outdoors (please don't tell Greta). Agreed, no oil mist in the shop. -

Now the proud owner of a 2002 SayHa SSM-50. I want to put a muffler on the exhaust (outside wall exit). These aren't really noisy hammers to begin with but with mufflers shop noises are greatly decreased. They come with a lawn mower style muffler which I don't think do a very good job as owners I've seen have removed them and installer larger mufflers (motorcycle/car sized). I don't think the moisture content and lifecycle of the muffler is a big deal but I'm curious if there are considerations as to mufflers for power hammers like moisture (rust out, toxic chemicals, etc.) or will just any old muffler do? Sincerely; Over thinking it in North Carolina.

-

Best Daylight/Throat for BLACKSMITH Press

stickermigtigger replied to stickermigtigger's topic in Presses

No sir. I wasn’t able to verify their curriculum vitae. But I do know it was one of their service techs. I’m sure he was clueless though. -

Best Daylight/Throat for BLACKSMITH Press

stickermigtigger replied to stickermigtigger's topic in Presses

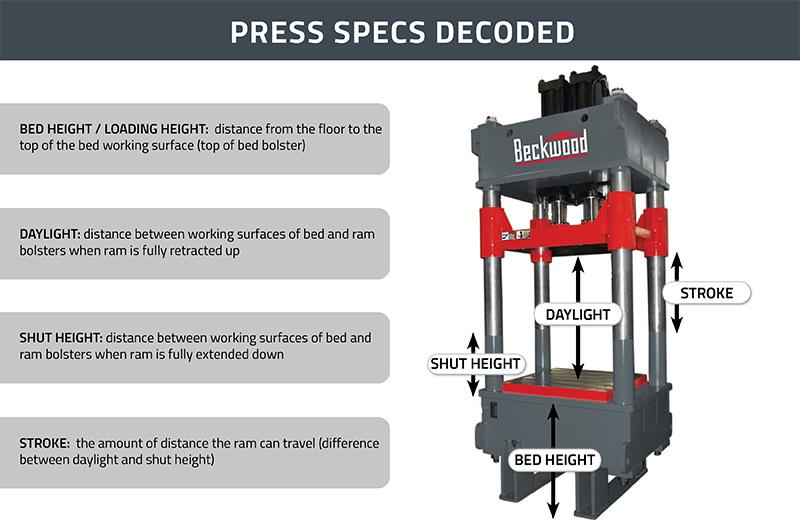

One of the forge press vendors I queried responded with this definition of daylight used in the spec sheets: - "The daylight is the amount of space between die receivers when there are no dies installed and the cylinder is fully retracted." That looks close to the definition of 'shut height' in the graphic above. Frosty: true. But they have a list on that page with definitions and they use this definition: -Throat Clearance: On c-frame (gap-frame) presses, the throat clearance is the distance from the vertical centerline of the bed to the back of the press behind the bed. This measure is required to determine the diameter of parts and tools that can be positioned within the press. So throat isn't relevant to my need. -

Best Daylight/Throat for BLACKSMITH Press

stickermigtigger replied to stickermigtigger's topic in Presses

Must not have been using the right keywords AND should have looked at images for my searches. Here's how Beckwood Corporation defines daylight and throat. Using the images as hints leads to many other documentation from other corps. Turns out neither applies 'directly' to the distance I'm looking for but can be used probably to calculate it. In this graphic it looks like what I'm looking for is 'Shut Height' with die thickness considerations. -

Best Daylight/Throat for BLACKSMITH Press

stickermigtigger replied to stickermigtigger's topic in Presses

Too far into C-frame build to go a diff route. I’m using the term ‘anvil’ to describe the upper and lower masses that will fill the non-‘daylight’ space between the base and the ram. Your definition of ‘daylight’ is the distance I’m looking for. Only looking for the best value of ‘daylight’ here. -

BLACKSMITH focused please. I don’t make knives. The largest average part made would be hammer heads (use five pounds as a norm). I’m at the point of building the anvils in my press build. I need to determine the best ‘between the dies’ opening. Any idea what the average/best distance between the dies would be for a blacksmith forge press, cylinder at rest (retracted)? 10 to 11 inches (CoalIron/PiehTools) is what I found researching, but I’ve seen several in photos and videos that appeared to be inches less. Also, I can’t find the definitions of throat and daylight. I would have thought they were the same thing (distance between the anvil faces????). But I see them used in spec sheets and with different values. Questions: 1. What are the definitions of ‘daylight’ and ‘throat? 2. What would be an ideal distance to have between the dies?

-

Repurpose Air Hammer Chisels????

stickermigtigger replied to stickermigtigger's topic in Tools, general discussion

The Horr video was interesting. Definitely 180 degrees from where I was taking this but glad to find a new technique. I have that type of hammer; just never thought to use it forging. :-) My question focus is what is the 'steel' used to make those chisels good for repurposed to for other uses like chisels, punches, cutoffs, etc. -

Repurpose Air Hammer Chisels????

stickermigtigger replied to stickermigtigger's topic in Tools, general discussion

Looks like a few videos on Glenn Horr on YouTube. I'll watch and see if he mentions anything about this. Thanks for the tip Shainarue. -

Repurpose Air Hammer Chisels????

stickermigtigger replied to stickermigtigger's topic in Tools, general discussion

Yeah, I'm no authority on jack hammers and their chisels so I can't ask the question in that detail. They pretty much all look about the same to me. 1 1/8" suggests "jack" hammer. I've been looking at the smaller chisels one might buy at Lowe's for a small to medium contractors air hammer. Here's an example (or smaller). I'm not looking at 'specialty' equipment. -

I run across a lot of old air hammer chisels and they're usually pretty cheap. Google gives some examples of types of steel in them: chromium molybdenum, s-grade tool steels, and others. I don't see any threads on forums though of people repurposing them in a blacksmith shop. Are any of you using them as a steel stock; what are you making with them; what treatment processes are you employing; etc.?? Thanks.