Bodhi

Members-

Posts

8 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Black Mountain NC

-

Interests

Blacksmithing, Woodworking, Guitar, Primitive skills

Recent Profile Visitors

77 profile views

-

Mikey: Good spot, I will make sure to straighten the mig tips out and yes the brick is light weight insulating fire brick coated in itc-100. Frosty: I might try switching out the T first because I don't think that I want to be pushing more fuel. From what I have read my to burners in this forge should be plenty of heat and I want to be as efficient as possible. Does that seem like a good idea? Do you think it will be okay if I just cut the end off of my mig tips and then maybe clean up the edge a little with some fine sand paper? Lastly, I will definitely try pulling me burners further out of the forge. Thank you all for the advise, you guys are so generous with your knowledge.

-

Alright, so I have finished lining my forge with kast-o-light and painted it with itc-100. I put one of my doors on and am at this point trying to test my burners in the forge. So, I tested my burners out side of the forge and they looked like they had been working well. I then put them in the forge and tried to fire it up. The burners would not hold a flame, they would cough and light up for a second and go out. When I tried lighting them with more pressure it looked like they were blowing themselves out and at lower pressure it would light up for a second and go out. These are the plans that I followed to make my burners (they are T style venturi burners): https://youtu.be/SAP8Xho_I6w These are all the parts I used: 1x1x3/4 Tee - 3/4 x 6 Nipple - 3/4 Merchant Couple - 3/8 Flare x 1/4 MPT - 1/4 Flare x 1/8 MPT Union - 1/4 Flare Swivel - 1/4 Flare x 1/4 FPT Elbow - Mig Tip (0.030) - If that link gets taken down, basically what I did was drilled and tapped the reducer T and screwed the 1/4 Flare x 1/8 MPT Union into that and then tapped the 1/4 Flare x 1/8 MPT Union and screwed the mig tip into that, then put the nipple onto the T and put the 1/4 Flare Swivel onto the 1/4 Flare x 1/8 MPT Union, put the 1/4 Flare x 1/4 FPT Elbow on that and the 3/8 Flare x 1/4 MPT on that. What you end up with is that you hook your propane up to the 3/8 Flare x 1/4 MPT which connects to the 1/4 Flare x 1/4 FPT Elbow which connects to the 1/4 Flare Swive, which connects to the 1/4 Flare x 1/8 MPT Union, which connects to the Mig Tip inside of the T that is connected to the nipple. I hope I did an okay job explaining that, the video make it much simpler to understand since you can see everything. And I attached some pictures of the burners inside the forge, so I hope that helps. Anyways do any of you know why my burners are not working and/or how to fix them? Thank you so much in advance

-

Ok, so I got the burners holders installed (I went with frosty's advice) and laid 2" of super wool, then rigidized and lastly cast my kast o light on top of that. My question now is what is the best way to cure my kast o light? I am hoping that I can do it with just my ventiri burners because I don't have a good oven or much electricity. I have already allowed it to set by mixing it, applying it and then letting it sit in 100% humidity for 24 hours. I have read around that it is best to heat it up in incrementally 100f per hour, should I try doing that with my burners (I don't think I will have much accuracy)? Anyways what is your guy's recommendations for how I should cure my kast o light?

-

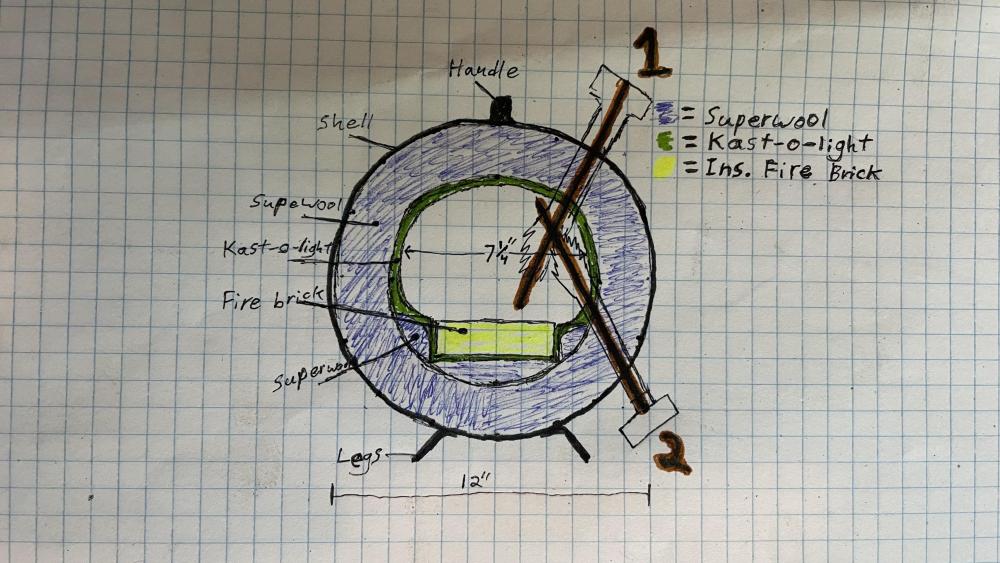

Thank you all for all the input. I am thinking to position my burners so that I get a little bit of a hot spot. I have made a little drawing of what I plan my forge to look like, so I hope this helps you all get a better idea of what I should do. I drew two different positions for the burners, but am thinking to do position one in this drawing to get a hot spot. Does position one look good to you all? Would you recommend tweaking anything? Thanks again for the help!

-

Okay, I have finished the shell and am now ready to install my burner holders. This is what the forge looks like now. I am wondering where you all think I should put my burners (I am using two 3/4" ventiri burners). I am going to put at least 2" of super wool (it performs essentially the same as koa wool but is supposed to be less toxic), 1/3" of kast o light and then itc 100 with a insulating fire brick floor. So the inner chamber will end up being essentially D shaped. From looking through the burners 101 thread and others it seems like their are four main positions people recommend: 1- placing the burner at the top of the forge angling straight down (this is to purposefully create a hot spot) 2- placing the burner at around 2 O'clock angling the far bottom corner 3- placing the burner at around 2 O'clock angling straight across (so that the burner is level) 4- placing the burner at around 4 O'clock angling upwards as much as possible I attached an image below with the burner positions drawn and labeled. So my question is: what are the different advantages and draw backs of each of these positions and what would you all recommend that I go with?

-

Ok, I was initially leaning towards buying a burner, but I will look back into building one. Just off hand what do you think of the burner that red beard ops shows how to make for $21 (it is a frosty T design)? Maybe I will make two of those? Also do you have any thoughts on any of this: I am planning to make some doors for this, what size opening am I going to want? Do I need to have it closed up enough to get a back pressure for the burner? What is the best orientation for my burner, to get a good swirl/turbulence and even heating?

-

Hey Frosty, Thank you for the quick reply! This is the information that atlas knife provides on there website were I am thinking to buy it from: 100k burner produces 105k BTU @ 20 PSI, 6″ burner tube length, 1.050″ outside diameter, Stainless steel and brass construction. All fittings are custom made, steel 3/8″ flare 45° fitting. Thant is all I know if you go to atlas knife and search Atlas Custom Burners you can find the listing petty easily. I am expecting the finish volume to be about 450 cubic inches. Ok, thanks for letting me know about the refractory I will try and get it here. I think the ITC-100 is dry, it says to mix 2 parts of the ITC with 1 part water. I hope I answered all your questions, Thanks again for the help!

-

Bodhi started following Propane Forge Build Questions

-

Hey everyone, I am a beginner blacksmith, I have forged a few things like knives etc. with others guidance. I have recently taken a more serious interest in blacksmithing and am planning to build myself a propane forge. I have done a ton of research online on this forum, others, as well as youtube and more. I am pretty sure that I know what I want to do, but I wanted to post my plan here in case any of you have suggestions on how to do it better, or tips and tricks for some aspect or otherwise have some advice. Before I get into my plan I am going to tell you all what I am planning to be blacksmithing. I plan on just doing a variety of simple projects to get started and see what I like. I am thinking of things like knives, hooks, tongs, fire strikers, utensils, bracelets and simple tools. So now for the plan: I am going to use an old 20lb propane tank as the shell (I will make sure to fully clean it out before I cut into it). Then I will put in two layers of 1” kaowool all around with more on the bottom to make a tray that will hold an insulating fire brick (this is so that I can replace the brick when it gets worn through and so I have a flat floor to set my work). I will then spray the kaowool with rigidizer (buttering it first). Next, I will coat all the kaowool with 1/8in of selenite (maybe a little more) and apply ITC 100 to that (again buttering first). Lastly, I will insert my fire brick floor and coat that with ITC 100 as well. I am going to use a venturi burner (the 100k medium one from atlas knife) that I am thinking of installing on the side just above half way up the tank angled slightly downwards. I am hoping that this will allow me to get up to forge welding temps if I want. Please feel free to offer any advice on any part of my plan, but here are the things that I am not sure about: I am planning to make some doors for this, what size opening am I going to want? Do I need to have it closed up enough to get a back pressure for the burner? What is the best orientation for my burner, to get a good swirl,turbulence and even heating? This is the list of all the supplies that I am going to get and where i am getting them from: Propane tank: I already have Kaowool: Hightemptools Inswool 1" (from Hightemptools) Rigidizer: Colloidal Silica Rigidizer - Coating for Refractory Ceramic Fiber Products - 1 Quart (from Amazon) Satanite: MR VOLCANO Refractory Satanite 10 Pounds for Ceramic Blanket Lining 3200 Degree Mortar (from Amazon) ITC 100: Mr Volcano ITC-100HT (1 Pint) (from Amazon) Fire brick: In store Venturi burner: Atlas Custom Burners 100K medium Burner (from atlasknife) I will post pictures when I get the supplies and start building if you all want. Thank you all so much for your generosity with your time and knowledge.