Wetsuit29

Members-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Byrdstown Tennessee

-

Interests

Machinist, Sailing, Babbitt Bearings,

Recent Profile Visitors

82 profile views

-

This is the tool I made for checking and setting the oriface precisely on center with mixing tube. Might be extra, but it works and works good.

-

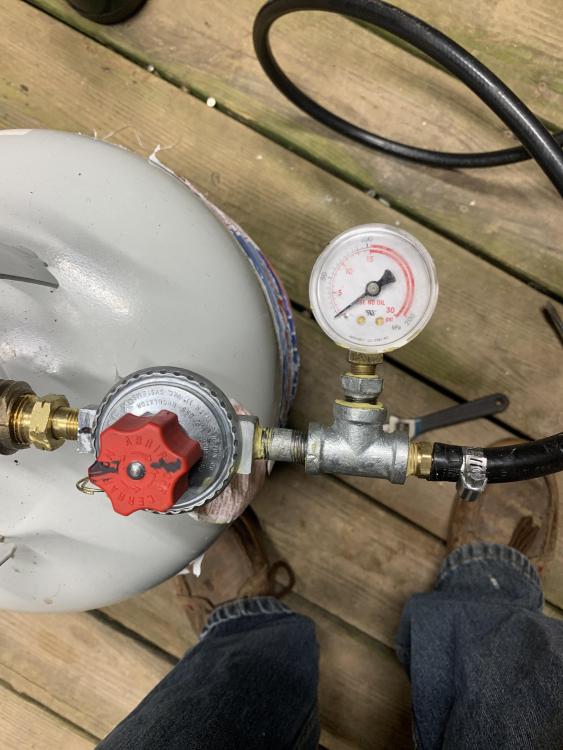

The pressure gauge is temporary, just to build and tune the burners. For some reason, the burner with the coupling flair cuts out over 9 1/4 pounds. Don’t know why, but I intend to trim the jet back an 1/8th. That’s the one that seems a bit rich. The other burner has a tapered coupling in the shop. I intend to take a Thought that Frosty had about the threads in the flair being helpful. I cut a 5 degrees per side taper in them, and the one in the shop, I going to “Ripple” that taper, just cause and to see side by side what the difference might be. Cutting “Ripples” on a taper is kind of my idea of a pleasant evening. so, again, I’m on hold while I build my outdoor Work Bench. Then I will build the forge. Till then, I’m going to fix this header.

-

I have to be quick, I have a couple of bonafide jobs to knock out before AM. money is a Header for a V8. I Think I have everything to go into forge build, except a table. I’m going to do that next while I wait for K-wool to come in. So, I’m off the burners till the table is done. I MIGHT do a sailboat inboard engine trick, Vacuum gauge on the mix tubes, just for my curiosity. I’m pretty sure I can match them precisely, just like barrels on an old style carburetor. Not sure, but, I might. Frosty, you ever run into a guy up around Wasella named Burris? Originally from Idaho Falls Idaho? I have to knock out this header, TTYL

-

Alaska?!?!? That’s a stretch….. How about I take a bunch of pictures of the York Place ad make them available. I already have a ton of photos of his Grist Mill. The entire building is a machine, instead of machines in a building. I purchased a 0-20 high pressure high volume regulator today. It does work better then the acetylene regulator that I was using.. I will have to add a pressure gauge though. I moved all the Burner stuff outside. I need to stop and build a Table/Bench before I go further. I’m not ready to move into the shed, I have to install more and better lighting first. Just more stuff to do, or as I often say, “It’s just boats” I ran the burners outside and together. One seems to do really well, the other a little less. I have different flairs on them just to see. Merchant Couplings are over 6 bucks here, I’m using regular couplings at 1.69 each. I have still photos to attach, but cannot guess the pressure. They seem stable all the way up to 20. These photos are with the regulator half open. The plumbing is temporary. I forgot to take a photo, but I made a tool to check if the mig tips are centered. Works pretty good. Alaska! That’s a stretch!

-

If you want to see this part of the world, you may not need an RV…. You can consider this an open invitation. Perhaps you should send your email or messenger. Wait,,,,, where do you live? We are right between Cookeville TN and Monticello KY. One of my biggest safety challenges that I have to constantly work on is what the grinders give off. It’s always a challenge keeping ahead of the grinders. They are subtle and unforgiving. Tonight I discovered that the dia of my two mixing tube’s were quite a different, but, both were schedule 40 3/4 black pipe. .785 vs .835. Both Burners are identical in every other way, but one rocks the other (the smaller one) barely will stay lit. Long story short, both tubes are identical now. Tomorrow I will try them to see if that was it.

-

Very interesting post….. I do have an out building that used to be a Model A garage, it has power and lights. I don’t know if I mentioned it, but this house was built in 1924, ad most the walls (brick) are a foot thick. It will burn though, all the lumber is Rough hewn 100 year old oak. I thi might be taking some safety issues for granted.I appreciate you focusing me on that. My 250 gallon propane tank has a regulator on it but I don’t know the rating. I intend to plumb it to the basement to run our gas fireplace that’s upstairs, or something like it. When the tornado ran over Cookeville, ( my nearest city) a couple years ago, folks were in shelter for a few days. The basement is a shelter first, shop second. All my hot work is being set up to be done out back. The temporary black hose in my photos is propane hose. But, it’s temporary. Im going to Sergeant York’s house this weekend. The are setting up a blacksmith shop in his yard, LOL, along with the infantry trench…. I will see if I can glean anything from them with respect to the local area. BTW, Sheila said that since you had extra forges, that you should send me one instead of me making her pay for my own….. Sheila is my wife. CFO, CEO, Boss/ Fleet Admiral. She administrators all finance. The biggest concern about logistics is not only the correct stuff but the correct quantity. I will refer to this site first. I do not see the Brands on Amazon that are recommended on this site.

-

Well, That is a lot of information to get started on. Air Gas told me that my small acetylene regulator was safe for propane but not my heavy duty Smith Miller. The adjustable High Pressure Propane Regulator’s are all over the place. I will get one today. I usually go with Air Gas, as I have propane cutting tips for my small Victor torch. I got them from them. Today, I will test my second burner, and might make a third, just cause I like spares on hand. I will also set up propane delivery plumbing to where my forge will live. I also have a 250 gallon propane tank that I will tie the basement into. I have a large roll of 1/2 copper tube that I will use for the longer runs. If life allows I will do an Amazon order for proper refractory cement and insulation. Like I said, I only like to build things once, so I will probably just suspend the CFO’s basement budget until this project is up and running. Of course, before any of this, I have to go survey the acres, out buildings, pond, etc for damage from the storm last night. Weather radio alerted us about 1:30 am….. had to heard 5 dogs, etc. I think we are going to be fine. So, I’m all in on the forge, regardless of the resources necessary to build it. please keep the advice and feedback coming and I will keep on building.

-

Yes,,Life is good. im only running the burners in the basement to get it established. I think it’s ready to go outside. i built another burner today, Precisely identical to the other. The Jets are .035 jets. I also have .030’s for my welder and some .023’s. Not sure where they came from. My wife asked me why I don’t drill my own holes….. I replied that I don’t have those kinds of drill bits or a proper chuck to hold them. She’s given me some drill budget. Lots of politics in my shop. To start a forge, I lack materials. All I have on hand is an 8 x 24 terracotta chimney flue and 3- 20 pound propane bottles….. and a ton of 100 year old bricks. I would rather build one time correctly, so I’m going to study your site then order materials. Since I have no experience with this, I will probably order extra everything. so many things….. Need to send my large Smith regulators out for rebuild. My Smith Oxygen regulator leaks like a sieve. Its always something. We have a large storm here tonight, tornadoes possible, so we will all be in the basement for a few hours tonight. I think we will be fine. Walls 1 ft thick. Thank You for your feedback and assistance….. Without it I would be stuck with the WAG method.. .

-

-

Frosty, On the bow of my sailboat, we hit a sumurged log on Dale Hollow Lake, last 4th of July. I taped over it and finished the weekend. I have to wait till the weather warms up a bit before I fix the hole. Fiberglass does not like cold weather. I thought it to minor for an insurance claim. It’s above the waterline and it’s in a sealed compartment. I have Dremel and sanders. No big deal.

-

OMG! well, this is cool… M in the right place for sure. this photo and short video is my third test of my T. It seems to be burning inside my flair, which is 5 degrees per side. But, still, reasonable performance, I think. I will make one more and a spare and get them in some insulation and keep at it. I did notice a slight misaligned jet, which I corrected before this test. The photos should be self explanatory. IMG_0724.MOV IMG_0724.MOV

-

LOL, Right now, the San Juan21 has a hole in the bow to throw money in…. Fiberglass, Easy Peasy, Blacksmith stuff? Huge learning curve…. the Jon Boat is for the Bass Pond….

-

I seem to like the shop and forge first…. “Jaunder”, a San Juan21, is a very entertaining MONEY PIT!! Here is an upcoming project….

-

My current, if secondary goal with the forge is to make throwing axes. I intend to make around 50 or 75, and get them in the 127 yard sale. That is how I came to make my training hatchet out of an antique plow blade, which I’m sure is 1080, at least. I am pursuing the Frosty T burners because they are of simple design, made from easy to obtain, off the shelf parts. They are compact for the power (btu heat) they deliver. From an engineering standpoint they are facilitating. I made my training hatchet with my oxy/acetylene rig with a Smith Miller cutting torch. I could not keep my bottles full if I did that very often. It’s an hour drive to change out my bottles. My PRIMARY goal for my shop, including a forge is to have a modest repair capability during a time when the stores are closed or the shelf’s are bare. On demand repairs for say tractors or specialty vehicles which are common here in this part of Tennessee. At a minimum, a heat treatment capability is necessary. i only just realized that I probably could do small Babbitt bearings with this gear. Babbitt is extremely expensive for the home shop. There would have to be a compelling reason for me to get into those. Im starting to get my mobility and strength back, so I will most likely become more focused on this forge. Most of the stuff I do, I do sitting down. I hope to ramp up in the next couple weeks. Hmmmm, Forge, or Sailboat….. It will be a serious time management issue.

-

I appreciate your post and advice. I do recognize the utility of your methods and they are valid. I do think there’s a misunderstanding regarding my method of fabrication. Sometimes I use all my “stuff” because I’m bored or I’m politicking. For example, I NEVER use my 3 jaw chuck. I’m probably faster with my 4, in any case. It’s just in my DNA. For various reasons, I always dial stuff in. Is it necessary? No, it is not. But my shop is not a commercial venture, but for my pleasure….. No boss. I had intended to rely on coal. Surprisingly, coal is hard to get in this part of Tennessee. So, I got into this propane thing. It’s my intention to have charcoal, Coal and propane. I hope to do little projects just to teach myself. I don’t have an anvil, but I have several feet of railroad rail. My shop is all about managing with what’s on hand. Three Jaw….. LOL, I would get fired in my last profession (Babbitt bearings) if I ever set up a Three jaw. i also have removed all things metric from my shop, but was frustrated when I discovered the MIG tips were metric (6mm x 1.0) yes, I had to buy a metric tap, but let’s not tell anyone. BTW, The T Burners are miniature versions of what is used to pour the larger Babbitt bearings. It has me thinking about developing that capability (bearing work) on a smaller scale. The Sergeant York Grist mill is full of the things and they are all seized up. life is good. If it looks like I’m screwing around in the shop, it’s probably because I’m bored and am just horsing around. Thanks again for reaching out.