Dr.X

Members-

Posts

10 -

Joined

-

Last visited

Recent Profile Visitors

38 profile views

-

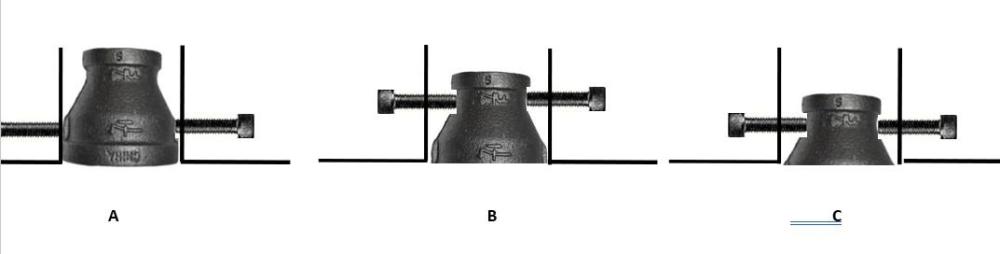

Gents, While I'm waiting for the paint to dry, I was reflecting on your posts. Based on David's comment, I wonder if it makes sense for me to cut the flares down. (BTW, I noticed/remembered yesterday that I'd removed the threads inside the bells, making the cavity even larger!) A is what it looks like today. B and C are options. Always compromises: -I worry about the mechanical stability of B and C. The sleeve walls are thin, and the cap screws loosen every time I fire up the forge. -the space between the sleeves and the reducers will get larger in B and larger still in C. Frosty, you said this might keep them cooler, though I wonder if it will also allow heat and possibly flame back up. What are your thoughts? PS. What about using the stainless sink strainer flame holders?

-

Now I get it Frosty. Thank you (all) for taking the time to help out a strange dude on the internet. I didn't know everything you guys just explained previously, but even if I had, a flare would have been necessary unless I went 1.25 inch from one end to the other. Which would increase the costs exponentially. I imagine I would also need a much bigger air source to keep the velocity up enough with pipes that big. Hopefully I can make it work with what I have. I'll get to work on it.

-

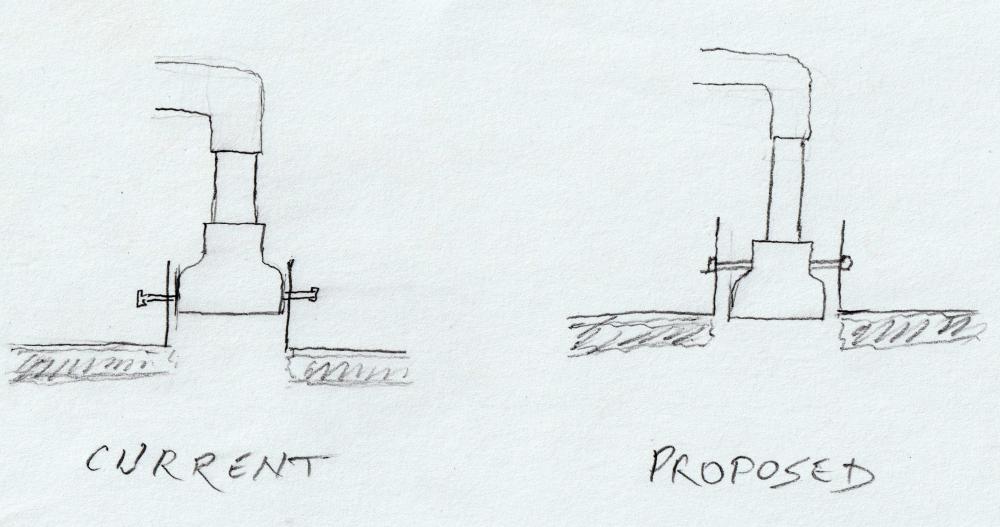

Sorry Frosty - we cross-posted. To make sure I understand - is the drawing below correct? Clarification: the end/bottom of the sleeve is flush with or 1mm above the shell. This is a 'store' bought, not made by me forge. And the refractory blanket is coated. I had to cut away a little at the entrance of nozzle and didn't re-coat it. I will rectify that immediately.

-

Whoa. That's an intriguing suggestion. I thought the fact that it was forced air should "keep things moving" rather than cause a ton of mixing to occur in the nozzle itself, but I see what you're saying. Am currently going from 3/4" to 1.25". I could go from 1" to 1.25 inch. To keep costs lower I could replace the Tee to a 3/4 --> 1 inch one and convert everything downstream from it to 1 inch. OR, if I could find reducing elbows that go from 3/4 to 1 inch that would be even better. I already have one 1in-->1.25 in reducer. What do you think?

-

Whoa. Thanks for the warm welcome Frosty! Your posts provided a lot of guidance when I was researching how to build this. RE: the second paragraph in your reply above. What I did was to increase the propane a tiny bit via a needle valve - I did not decrease the air (which I suppose accomplishes the same goal to some extent). But this should not cause the flame to burn in the burner tube if it didn't previously, right? To answer your questions: the sleeves are on the long-ish side, so the end of the nozzle sits between 1/2 to 3/4 inch above the refractory. The nozzles actually end outside of the shell. Kinda hard to see in this pic but it's as good as my borescope will do: Certainly explains why the sleeves got so hot! So, #1 job (after getting and installing flame holders) will be to get the nozzles into the shell sitting a tiny bit into the refractory, as you suggested. Increasing the height of the forge would require me to get or build a new one, which I'm not prepared to do quite yet. BTW, there is virtually no space between the nozzles and the sleeves. I had to sand the black iron reducers quite a bit to get them to fit into the sleeves. What do you think about the color of the flame? Should I aim for the pure blue like at the beginning of the video, or the richer slightly redder version? Thank you again. Nick

-

Hi folks. I decided to convert a cheap Amazon dual burner Venturi forge I own to forced air. Did some internet research, but didn't do any calculations. Kind of winged it. It works pretty well, as you can see, but I'm sure it can be improved upon. Feedback/suggestions would be appreciated. I used pipe from Home Depot and decided not to add flow-straightening sink strainers at the business end of the burners. Seems to be OK without them. A few questions: -should I stick to the leaner blue flame as seen at the beginning of the video, or the redder, richer flame shown near the end? -the burners glow red after about 10-15 minutes with the richer flame. I imagine this is not great for the longevity of the unit, but is it safe? The forge will be used infrequently to forge small knives by me. I dabble in many things... Many thanks. Nick