Kliff

Members-

Posts

8 -

Joined

-

Last visited

Profile Information

-

Location

Southeast Wisconsin

Recent Profile Visitors

74 profile views

-

Yeah, Mikey, I thought about modifying my initial design much like you outlined, to accommodate 2 people using it, shut off 1/2, etc. Then I decided not to pursue the "holy grail" of forges, and start with a simple one, just big enough to do what I envision doing in the next 6 months. Worst case, I build another one in 6 months, with a lot more than WAG's to base it on.

-

I like the "door" design. I was just going to stack bricks. That would keep my fat fingered clumsy hands from knocking them all over the place while I'm working.

-

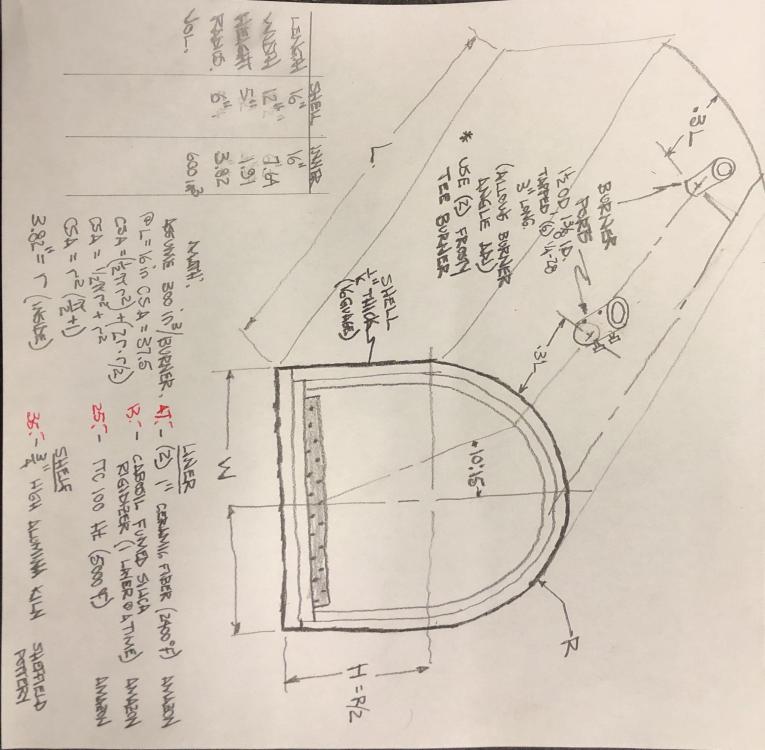

Thanks for the feedback guys. Mikey, I have read many posts under this topic in the last couple months. So much so, that I ignored some of your advice early on: keep it small, etc. I initially picked ITC 100 based on posts here. Apparently I confused it as an alternative to Kastolite, and not as a kiln wash. Without this thread, I'd be no where near as close to building a forge as I am. Just glad I asked for feedback BEFORE I ordered all the stuff. Although I do have all of the fittings for a two burner design. Oh well. I'll save most of it for forge #2. I'm pretty sure #1 will not be final. I'm reworking my design, and I won't bore you with pictures. It's basically going to be about 4.5H by 7W by 10L. "D" shaped. Single burner. port about 20 degrees off Top Dead Center. Aimed at approximately 1/3 of the way in from the near edge. Open on both ends, using kiln shelf pieces to close off as needed. 2 layers ceramic wool rigidized Kastolite (approx. 1/4" thick walls/ceiling, 1/2" thick floor Plistix kiln wash High alumina kiln shelf floor. Probably the biggest tool I can think of that I'll be making would be a series of draw knives. Oh, and a gigantic sword of course (no sword). For the most part, I guess I'll be doing a few knives, and other items approximately the same size.

-

I guess I didn't include all of the specs in my summary, but they should be in the drawing. Interior volume is 600 cu in. My primary use will be forging my own tooling and knives. Don't see myself ever selling anything. I came about my sizing this way: Started with ROUGHLY 5" HJ * 7" W * 12" L. I started here, thinking the 5*7 cross section is bigger than I need, but big enough to put stock in without banging on the lining too much. At this size, it's 420 cu. in. Too big for single burner. So I decided double burner, then worked sizing backwards. Keeping ROUGHLY the same cross sectional area, I started with 600 cu. in. (300 per burner). That's how I got my 16" Length. Then starting with mailbox shape, where W= 2*R and H=`1/2R. I used these ratios for two reasons: They seem reasonable, and they make the calculations simpler. That's where I derived all of my interior dimensions. Exterior, I added 2" in each direction, and rounded up a bit to account for the hard liner. I was planning to use ITC-100 as a liner over the wool blanket, followed by a kiln wash, not yet mentioned. Haven't found an available source for Plistix 900, still looking for Matrikote. I'm looking at needing 1 pint of ITC-100, so $25 isn't a deal breaker. I was also looking at Kast O Lite 30. Might be cheaper per pound, but I don't need a 50 lb sack. I was planning to aim the burners at about 1/3 of the way in from the edge, not the center of the floor. In looking at my own drawing, I can see why it looks that way. That line is used to indicate the penetration of the burner ports is not Top Dead Center, but offset to one side at about 10:15 (using clock angles). Thanks for your input

-

Ok. After quite a bit of reading, and research, mostly here, I think I'm ready to build my first forge. I'm hoping for a little feedback on my design before I start. I'm planning a double burner forge, using two Frosty T burners. I've attached a photo, with calculations, and descriptions if anyone is willing to take the time to review it, it would be greatly appreciated. It's basically: -a mailbox design, 16" L, 12" W, 11" H (Outside) -1/6" (16 guage) shell. This will allow me to weld burner ports & feet on, yet keep it light enough to easily move -(2) layers of ceramic fiber blanket rated to 2400 degrees F -rigidized using cabosil fumed silica (one layer at a time) -coated with ITC 100 HT (rated to 5000 degrees F) -high alumina kiln shelf 3/4" thick, cut to fit bottom -two frosty Tee burners (3/4") placed at about 10:15, placed .3*L (about 4 3/4") in from each end. Mounted in drilled & tapped ports that will allow for angle adjustment. One question I have: Is the end of the burner tube mounted so it is flush with the final inner layer of the coating, or is it held back a bit? If you prefer, you can e-mail me directly: note email removed (use PM)

-

Thanks Mikey. Saved me a bunch of time.

-

Well, after reading your posts, and getting some solid advice, I'm ready (I think) to make my first forge. Planning to use Frosty's design for the T burner, fabricate my own shell, and line it according to suggestions I've found in other posts. One question I have, with a thought that goes along with it, is the connection between burner and forge. If this is way off base, someone please let me know. I'd build the burner as shown, and mount to the forge with a street 45 and floor flange as shown in Frosty's pic. on the bottom side of the floor flange, inside the forge, I'd connect a close nipple, with end turned down to match a TIG nozzle. size the nipple so the TIG nozzle is through the liner by approximately 1/2". I'm thinking this for two reasons: Proper nozzle size & shape, heat resistant nozzle to extend wear. A #15 nozzle should fit real nice: .... Commercial link removed....

-

This is great. Thanks. I know way more about heat treating than I did 1 hour ago.