Gandalfgreen

-

Posts

379 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gandalfgreen

-

-

Yes sir you are correct didnt want to ramble on as it is more woodworking haha but yes found the little fungi few minutes later that made it happen. Might make a ballpeen handle out of it yeah it could split but think I going to try. Also new handke for my tomahawk.

-

I'm checking tomorrow my owner told me about them today on my way out.

-

So I have two old tables at my job that have steel table bases to hold them down as they are what industry calls high tops. They are both 3ft round not solid has a pattern like vine or something to create gaps. Is this steel worth taking?

-

Thanks fellas appreciate all the info. Exactly what I was looking for.

-

-

Yes very true just eager to learn and nothing better then swinging hammer. Didnt get better knife skills without mundane cutting wont get better smithing skills without repetition. As a those dudes in the suits like to say it takes 33 days to form a habbit as they go home and give you more work. lol at this point my first project will be tent spikes anyone know a seamstress sew me some walls on my sonp area slash tent I will build.

-

Hammer time equals learning where you want the pile if spikes?

-

Ok got it what ever the form grease xxx xxxx out if it or it will be part if my forge. Or no form and do half at a time.

-

BORK BORK BORK UNDERSTOOD

-

Still getting use to site forgot to follow after posted thanks to all who responded and yes just time to do it. Havent stopped thinking about hammering a piece of round bar square again since my day with John.

-

Have time waiting see if buddy can make and already started backup plan. Have time didnt get silica coat on like planned was not sure if could go few days before I fire dried it and have busy schedule today thursday and friday. So more sponging of info for now till next week.

-

BORK, BORK, BORK!

SWEDISH CHEF READY TO LEARN NEW ART!

-

Ted that's a beautiful piece.

-

Ok thanks see what I come up with. If not printer have another idea with old plastic cutting boards.

-

Thanks for all the input fellas and hope I'm not a bother. Have a question pertaining to the kastolite I wondered if I sticks to plastic because I have access to a 3d printer and was thinking about printing a form to insert into my forge and then apply kastolite allowing me to coat all sides of my not quite circle not quite oval forge.? Thoughts ideas waste of time let me know thanks Gandalf.

-

When doing the silica stage if I let it air dry longer then a day before I fire it will it affect the end result. Mainly asking wanted to coat it today but not sure if have time tomorrow or next day to fire cure it.

-

Okay thanks for the information. Maybe I will look into one if the others for it then. Glad I asked makes sense. Again thanks Frosty

-

On 6/20/2018 at 2:40 PM, Frosty said:

However an IR re-radiating kiln wash makes a forge more efficient and extends the life of the rest of the liner. ITC-100 is the best known name but is NOT formulated for what we do. In reality it's a release agent to prevent gunk from sticking to furnace flame faces, the 70% zirconium content is for it's nearly inert nature not it's IR re-radiating properties. It's also CRAZY expensive, go with something formulated for our purp

Frosty I am in the process of protecting my forge with all the layers and have a question I just noticed your comment and when I got my forge I was also given ITC-100. Should I save this and use a different final coat like the 2 you stated at the end of your post?

-

Wrong word meant nothing not anything. Haha but I get what your both laying down.

-

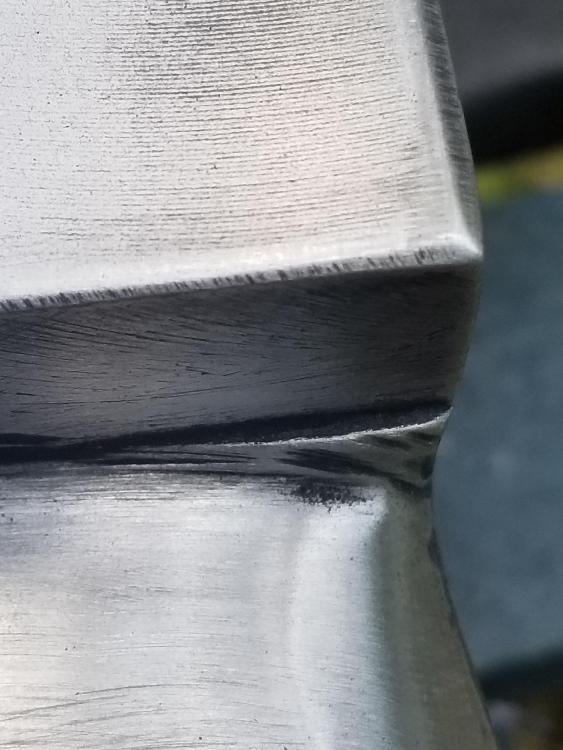

Thanks I just was not sure and was worried doesnt look like crack but definitely a groove, fissure, or grinder gouge and being new didnt want to do anything before was too late. And I agree John I been looking at all different kinds so can use hopefully a good piece a scrap a know what to do. After using your metal one definately look8ng go that route.

-

-

Not that I'm aware of literally just got into blacksmithing so everything's new haha. I have a friend hoping will go he can hunt toys while im there. Try and figure something out sounds like a good event.

-

I want to need to figure out the dates and make sure no events at work and save money to get in. Have seen a few posts about it on here since I joined.

-

Yeah I have heard that but havent seen one yet lol but have not been to that event yet either. I'll get lucky one these days

Scrap metal question

in Blacksmithing, General Discussion

Posted

Frosty you noticed my horrible phone typing. Its something that I cant fix in my circle of friends they have learned my language and called it Wisethumbs say my thumbs have ther own minds. They all hate that they can read and understand some of the garbage I can send when really rambling. Have your fun with it we all do even I cant translate.

Owner of the buisness I work at.

Unless that wasnt a dream.....