DoubleG

Members-

Posts

18 -

Joined

-

Last visited

-

Billy I get the idea! Great advice thank you sir!

-

Excellent advice sir! Will do!

-

Thanks Buzzkill! I was having some trouble getting the forge back up to temp and had a hot spot in it, that would make sense!

-

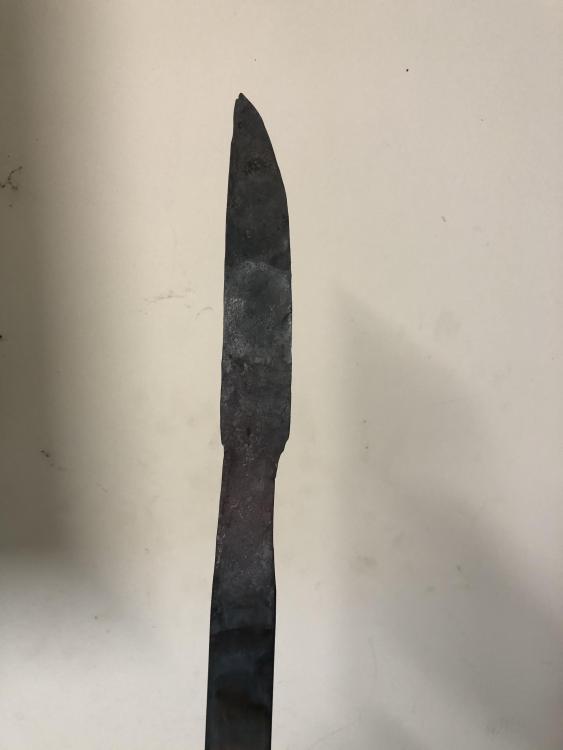

Nice! The sander is under the Christmas tree and I’m patiently waiting! So not much progress on the knife, however after quenching I did see something odd, I ground it smooth before heat treat but I had this odd pitting once ground after quenching.

-

Haven’t made it to the local Steel supply yet but found a decent one online here in Indiana, will get out there Monday to get some good tool steel. Was playing around yesterday trying to have a go with some hot rolled steel I got from Tractor Supply. Just working with an angle grinder now, but the wife signed on to get me a Palmgreen 2x42” belt grinder for Christmas (all we can afford, and xxxx !! Those nice ones are expensive!!).

-

Thanks for the Tip IronDragon, I had no idea! I didn’t know! So how is scale not formed in gas forges with no fuel at all surrounding the metal?

-

Woah fellas! It’s all good, everyone being helpful and keeping us newbies safe! Thank You! Moot point anyway as you can see I now have some less cancerous firebrick in its place. I used to build kilns as a younger man and I get irked by the inefficiency of an uncovered forge, this way I can get great fuel economy and high temps! Practicing on some weld steel today, cut some 4” bars and sanded and welded them, also put the Borax under my bench to use today!

-

Wire I used to be a potter and have used kaowool for years. I don’t really think it poses so much of a threat in the manner I used it but I like to please posters in online threads. I’m trying to refrain from piling coals on top as my chimney draw is small so I want all my coals red hot but a small amount at a time. So far she’s working perfect.

-

Totally improvised, borrowing it from a buddy. It’s railroad track with a large piece of half or one inch bar stock welded on top. It’s working for now for “playing” but it’s #1 on my list to replace when I find a deal. I don’t have $800 for an anvil. I have $200....lol!

-

George and Frazer thanks for the advice! Turns out I have a 5lb box of Borax sitting next to the forge, just didn’t know I could use that! Live and learn! Also I’m reading there’s quite the methodology for forge welding, lower heat flux, soak, secure welds with lighter hammer strikes, higher heat, forge weld with harder hammer strikes. I love it can’t wait to give we a go! Yes squishing hot metal is fun!

-

Frazer you must be a fortune teller. As today on my list was exactly what you said I would do. Minus the new firebrick gonna source that tomorrow. Just for fun I played with the new welder and welded 3 pieces of billet together and tried to forge weld them together. Probably need to get some flux in the future. First gotta find where I can find it!

-

Score IronDragon! That’s Awesome!

-

Bottle openers! Now that’s a great item to start with! I’ll give it a whack today! Haha! Frazer as always, you got good info mate! I didn’t even think about sourcing out junk material for practice. I’ll see what I can find around me. I also need to check out the local steel supply. I went to Lowe’s just cause it was convenient and I was itching to tink tink on something. I’m sure local steel supply is the way to go, they’ll educate me on materials and also cut to length just about anything for me I’d imagine.

-

Thanks for the tip Pnut! Frazer I’ve no idea what material it is just some flat bar stock I grabbed at Lowe’s. Most of the material I find at Lowe’s or Harbor freight I’ve no idea what it is, haven’t learned to read the labeling or understand different steels yet. I’ll get there!! Haha!