-

Posts

448 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Paul TIKI

-

-

One of my Twin boys's middle name is Samuel, After Sam Vimes. My Wife's favorite minivan was nicknamed Sybil after Vimes' wife (yes, we name our cars). Even my avatar is Sgt. Detritus with his trusty Piecemaker

The Going Postal Movie is OK. I liked it well enough even though it altered the story in some ways I was not too fond of. Sir Terry even had a small cameo in it.

I think my current favorite book is Making Money, but it wobbles around depending on my mood.

If anyone reading this has a pre-teen or early teen daughter, I HIGHLY recommend Terry Pratchetts' Tiffany Aching books, starting with "Wee Free Men". For your Daughter, I mean. You can read them too, but they are aimed at teens.

-

lovely ladies and you could be sure their heart, or hearts, were always in the right place.

The concept of an Igor with an adjustable lisp had me giggling for days.

Yeth Marthter.

-

She might also want to check out "Discworld Igor" as well

Sir Terry Pratchett wrote about them. The Clan Motto was "What goes around, comes around". They were skilled surgeons who were always ready to lend a hand, or someone's hand anyway

-

"This is the warranty management division. We have important information about your husbands extended warranty. If you would like to speak to a representative, press one now...."

Should you be concerned about all the spam calls she may be getting?

-

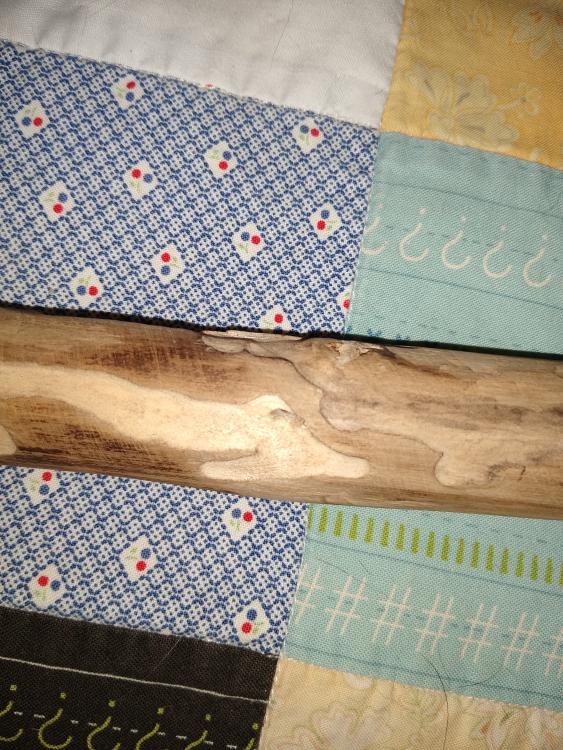

Not in the shop yesterday, but cleaning up some branches under our huge silver maple in the front yard. Been lazy and it included some deadfall from last fall. I found a relatively straight branch that felt pretty sturdy so I thought I'd make a walking cane with it. I peeled back the bark and found some interesting patterns created by some wood munching critter. Sanded it smooth then took a blowtorch kind of lighter to it to give a lightly scorched appearance to it. I might use boiled linseed oil on it for a finish, or I may brush on some polyurethane. Thinking a bear shaped cane top similar to a Zuni fetish bear. Probably attempt to carve it our of wood. I may try to forge something to go with it.

-

I'm imagining the smell...Wish it was still before lunchtime, dernit.

We try not to order anything temp sensitive to go through USPS. Will pay a little extra for FedEx if we absolutely have to. Not a surefire solution, but is usually better.

-

I'll be number seven.

It failed to rain yesterday and the wind died down for the day so I got out there and made another leaf. It didn't come out as well as I would have liked, but hey, it's all practice.

I also figured out what I did wrong with my tongs and got one side adjusted before I lost the light.

-

OSPHO might be another option. Phosphoric Acid solution that turns Iron Oxide (rust) into Iron Phosphate, which can act as a protective coating. You do need to get it all the way down so surface rust though. I know the stuff works and is cheap on lawn furniture and a bunch of other applications, and a gallon of the stuff is cheap and goes a long way. anyone else know how it would hold up in this application?

-

OK, got it. do not attempt to enclose tank. May cause large boom and that is bad.

It really is good to have that point brought up now and again. It helps prevent dabblers and fools like myself from doing something dumb, and in this case potentially lethal.

Is there a way to pin parts of this thread into it's own pinned thread? Maybe right along side of "DO NOT USE PLASTER OF PARIS". "DO NOT ENCLOSE PROPANE TANKS"

We all know that common sense is not too common. I like to think I'm pretty level headed, but this is a case that brought me up short.

-

thanks Goods. This is why I ask questions. It saves ones eyebrows among other things. I hadn't though of the potential for fumes, though I should have. I have a couple of drums and I haven't decided what to do with them. I am thinking of using them in a way that would shield the tank from the heat of the forge. Maybe by cutting it in half vertically and just setting it between the tank and the forge. I dunno.

-

so If I go with something like a 6 foot hose and house the propane bottle say, underneath a 55 gal drum with the forge being on top? Or would it be better for it to be out in the open, so to speak? On a stand next to the forge or underneath?

I have a weird Idea now of getting a long hose, running it through a PVC conduit with a couple of right angles and digging a trench and burying it. That way no trip hazard and tank farther away from forge. I'm probably making this more complicated than it needs to be.

-

Well, after talking to my son and looking at component costs and so on, It looks like I will not be messing around with the helium tank and instead go for a 6 brick pile gas forge with a Frosty T burner. that will get me a propane forge for the lowest cost. The Boy has decided to leave all of his forging gear here as his landlord doesn't care for the idea of blacksmithing on his property. Since he has some soft firebricks I can use those for the body. I have some scraps I can use for a framework and work shelf. So I can get that far without expenditure. I have seen high pressure regulators with 6 foot of hose on Amazon for 24.99 although I will keep my eyes open for things like used weed burners and such before I actually click the buy button. Plenty of sources for propane tanks. And since we are doing a number of projects that require running too and from the hardware store, I can get a piece here and there to spread the purchase of the burner parts out if need be. I found a pile of taps and dies that dad had, so I need to make sure I have the right ones, but that part should be covered. The Other Boy has a drill press I can use for drilling out that top hole, but If I can I'll try to talk the wife into letting me buy a new drill press.

I figure the longer the hose, the better, what would be a minimum safe length in Ya'lls opinion

-

My kind of dream house. I bet that was a beautiful sight. I wish my roof was something I could tend to with some fertilizer and occasionally dealing with weeds.

-

If you have the means to move that much earth in supersacks that would be a really neat for mof construction. I have watched a bunch of cool youtube videos on earthbag construction, and more recently earthships which use old tires. There is more to it than just that with the earthships of course. I even saw one really cool video of an arkansas (I think) Family welding some containers together and then burying them for a house.

Most of the Earthbag stuff I have seen uses cob to cover the bags and protect them from light, but I can't imagine that stucco would be difficult.

For a roof, I have been fascinated by Timbrel or Catalan Vaulting. You end up with overlapping layers of tiles that can create a relatively inexpensive but very strong structure that can be shaped in all sorts of ways. You can get pretty large spans without the need for internal support.

-

BIGGUN....I have always loved the idea of underground houses. That and basement man caves. I love the Underground house in Vegas that is basically a normal house built in a cave 26 feet underground. With the walls of the cave painted to look like the outdoors. Odd place, but very cool concept. Perfect for the desert heat.

-

I don't know about the brand, but I know I feared the styptic almost as much as a solid right

-

I remember the styptic pencils we used while sparring and got cut. those hurt worse than the shot to the face for the most part.

-

Billy Bones, I am using the silicone stuff as well. It looks like caulk, it acts like caulk, but the label says window glaze. It's setting up nicely. I went out and hand sanded what I needed to. I was going to paint but noticed there was a cold snap due for the next couple of days, so that scotched that idea.

-

I have a respirator appropriate for lead paint dust ready to go. I already did as much as I could with a belt sander and then a mouse type sander but stopped before I broke any glass. Removing the old glazing compound was mostly picking away gently with a pocket knife and a putty knife. Most of it popped loose at a touch, this was long overdue.

For the most part, there isn't much left to do with hand sanding.

-

freeing it from the paint, Sash weights, all good reasons for me to just seal it up. Less hassle that way

The paint still looks like xxxx It'll take some hand sanding to finish paint prep. I can't wait to see how it'll look when I get it painted and touch up the new trim paint.

-

That's a good idea about the shrink wrap, Not entirely sure how it would work over that window. Lots of different levels of surface. The window itself is supposed to be able to open, but it is stuck fast with 100 years of paint, warping and so on. I'm fairly sure I would break the panes if I tried to force it, so I'm thinking just going for a full seal up.

-

I got to spend some time forging yesterday. Another leaf. It went faster than previous tries, so progress. I figure I could be pretty good at them if I do another 196. I'm also getting better at keeping the fire at a consistent heat. I would like it to be hotter, but I'm consistent enough to be able to work. good enough for now.

I also improvised a holdfast for my improvised anvil that worked fairly well. Since I have a monolithic chunk with nothing like a pritchel hole or hardy hole, I can't use a traditional holdfast. What I ended up doing was taking an 8 inch C-clamp and clamped it to the anvil. I clamped it about 2 inches down from the face so there would be a "loop" and I could pivot it up out of the way when not needed. If I knew it was going to be needed I would make sure it was tight, put the piece through the loop and swing the loop of the clamp down to where it would hold it firm to the face of the anvil. It made adding the "veins" on the leaf much easier. It also meant I could punch holes in some things I am making for in house cat gates (The wife has too many cats and we occasionally need to separate them)

I also got to try my hand at re-doing the glazing compound around a 100 year old window. Patience is a virtue on that. You have to do things slowly and methodically so as not to break the glass. 14 individual panes. I'm glad we only have the one window like that. It's a picture window for the living room. It's pretty, so we are keeping it instead of replacing it like we did with all the other windows in the house. Once the compound sets It will be time to paint the wood. I think maybe adding a single large pane in front of the window to add some protection and increase the insulative value.

-

Nice Score Chad J.!

-

After having some painful and damp experiences with plumbing, I fully endorse paying plumbers for what they do. I have run the feed lines to our second story with Pex and sharkbites and that was successful. Once upon a time I tried to run a new drain line from the kitchen sink and it was...not.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

I have a pile of mower blades and have been wondering what to do with them. I'm thinking I may use them to make some simple Kiridashi knives. Flatten the mower blade, some gentle shaping and then sharpen. May also attempt a draw knife.