Bonnskij

Members-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Bonnskij

-

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks! I will certainly keep it to look back on as I improve. It's an interesting subject. Genetics has definitely never been my strongest suit, but I would be interested to read more on it. A lot of organisms have some type of plasticity in response to a changing environment, but I know nothing of the underlying mechanisms. And is it male lion with female tiger or vice versa for the liger? I know one coupling produces a liger and the other a tigon, but it's only the liger that grows so humongous which is quite facinating. I think I remember the first time hogzilla popped up online. Quite the beast. Cross breeding can lead to some quite unexpected results too. I think there was an attempt at breeding arctic foxes for a better temperament. Unfortunately, better temperament was also correlated with worse fur. Is the hybrid pig noticably larger than either of the two parent species? -

Justin’s Smithing progression. [PIC heavy]

Bonnskij replied to Justin Topp's topic in Member Projects

Here's a wood carving blade I had lying around made from 1/16 inch stock. How many do you think you could make out of your blade? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I think I read something recently about how domesticated pigs change quite drastically when they become feral. I can't remember where so I can't really verify that. I can't imagine it changes their DNA though, so sounds like somebody imported Russian boars to Florida as you say. Thanks. I sure hope so. I did not weld the socket on my spear either. As i understand 5160 (which I think this is) is pretty hard to forge weld to itself? I just closed up the socket and attached it to the handle with a single rivet through the middle. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

No it doesn't have a crosspiece. I had intended to do a bit of spear throwing with it, so I would probably clip myself in the ear if it had a crosspiece. Boar hunting with a spear sounds quite interesting. Too my knowledge there's a fair bit of hunting of feral pigs around here, and I think knives are the weapon of choice. Somehow it never struck me that a spear might be used for it as well. I wouldn't trust my spear though. I like the leaf shape as well, but this was one of the first forging projects I started. Charcoal in broad daylight, and I'm quite sure I forged it both too hot and too cold. Lots of stress fractures in the junction between socket and blade and it didn't harden properly. Decided to finish it roughly anyway, because I still like how it looks. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

So I finished my spear this afternoon. It has a lot of flaws to it, but it is what it is, and I will take my lessons with me to my next attempt at forging a spear head. I was an active javelin thrower more than ten years ago now, so spears hold a special place in my heart (plus it is of course the superior medieval weapon ). I still think it looks cool though -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks! I didn't actually pay that much attention to the terminus of the curls after I made them at the beginning, so that is definitely helpful and something I'll make sure to look out for next time. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

As advised I decided to try my hand at something non-knify. I remembered I had some 6mm round rod lying around that I was using as rivets. Figured that was about the right size for one of those hair clips I've seen, and thought maybe my other half might like one. I ran out of daylight so the pin in particular ended up quite crude, and I think the final bend in the bendy twisty bit was too shallow, so it doesn't fit all that much hair. It was fun though, and I'd appreciate any critique. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Well from now on it looks like there will be little time to go outside the house for a while. A couple of hours a day at work next week but after that the university will probably close. I've straightened the spring for the fullering tool, but haven't gotten the rest of the supplies needed. Will keep any shopping to a minimum, so might be a while. In the meantime I'm making some things out of scrap spring steel for myself. Because everybody needs a meat cleaver. And I need a draw knife. Or... Need is a strong word. I want a draw knife. I love draw knives and I miss using one. I've tried making one before, but it melted in my coal pit. Hoping the tang isn't ending up too short. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Temperature has finally gone down to decent, so I thought I'd do some forging after coming home from work. Alas. I ran out of gas. Happy with the accuracy of my hammer blows today, though I'm left with a dented monstrosity at the end of it. Earlier to work tomorrow and I'll pick up some gas and steel on the way. I was also going to straighten out some spring for a fuller/guillotine, but tomorrow it is if the weather holds. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thank you Chris! That will come in very handy! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Would be nice to have a smithing club around here too. Then again, I'm generally quite content in my own company for the most part, so I suppose I wouldn't show up all that often. Frosty: Yes. Norwegian living down under. No Queensland in Norway as far as I'm aware, but there is a Norwegian territory called Queen Mauds land in Antarctica. Did you have any particular kind of blades in mind? I think I can visualise how that works. Is mild steel suitable or should I get some spring steel or something? Think I've worked out how to make a small guillotine tool for the hammerhead as well. Some rectangular tube and stock should do the trick. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I do. I've been thinking of a way to make a fuller that would work with the sledge anvil, and think I might have something now. One day I'll have a welder... I see. I kindof thought it was a bit like cooking. I can make a great fish dinner. I'm not that good with pork. (unless said pork has been smoked, cured and sliced thinly beforehand). I cook great fish because I have cooked a lot of fish. I mean, it's almost mandatory as a Norwegian. So I've just figured that if i want to make good blades I'll have to practice making blades even if it means i stuff up along the way. I will certainly not argue that I am correct. I'm not exactly experienced at this game after all. That was just my thoughts on it, so I will take onboard any advice I get. I don't like getting frustrated either, and I don't all that often. I have a lot of fun with this. I would certainly like to know what projects I could do to improve on my bladesmithing skills. You teach bladesmithing at a university? Man I wish I had that option as an elective when doing my degree. My background is science and so is my job, I just never learned anything particularly relevant to smithing. I know a lot about fish though. I'll have to have a think about what blade hape to stick with for now then. That sounds sensible. I think I'll probably focus on something along the lines of puukkos. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

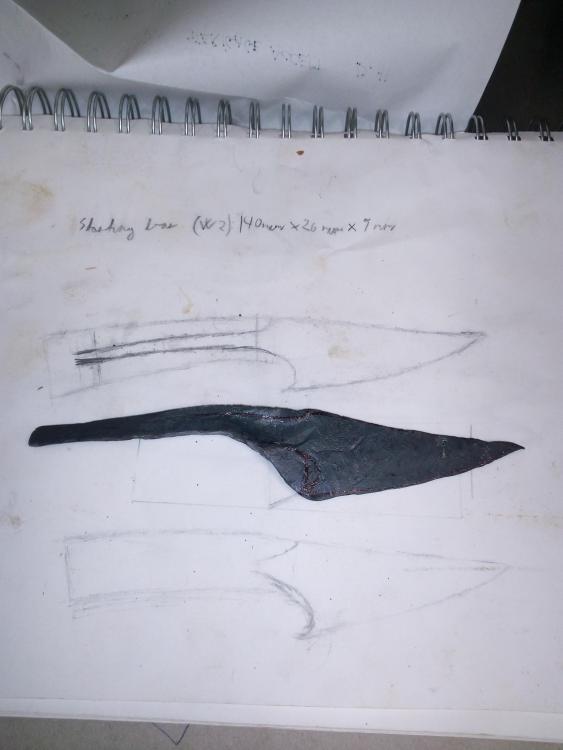

Thanks Frosty. I will be attempting basic blacksmithing as well, but my entry into smithing was a wish to increase my bladed tool set, and it has sort of just gone from there. That knife isn't my first attempt, but the profile is certainly the trickiest I have attempted, and so I have been messing up heaps on it. The first forged knife I started was the chonky kitchen knife on the previous page. The first one I finished was the krumkniv (which had a geometry about as suited to cutting as a baseball bat. All the other ones cut though). The first blade I tried to make however was a large drawknife. I burned that up in the forge while heat treating. As far as steel, at the moment I only have medium and high carbon ones. I figure if I'm putting the time investment into making blades, I might as well try to make them useful, and steel is relatively cheap anyway. Once I manage to make my way to the steel merchant I'll pick up some mild to play with. I've melted a couple of things in the charcoal, but mostly things hold up and especially after I switched to gas. I've seen some Nepalese blade smiths make kukris out of leaf spring on sledgehammer heads. It's incredibly impressive! Here is my current forging set up And here are two more knives in progress. The left one is w2 and the Sami knife on the right is 1084. They seem to have held up to heat treatments pretty well. The big knife is shaving sharp and the edge seems strong. I managed to get a hamon on the left one. I don't know if there's something I'm missing as far as being able to tell if I've messed up heating up the blades during forging though -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

It seems I don't have the option of shortcuts around here I'm afraid. There might be a tafe blacksmithing course at the end of the year or something. A book sounds like my best option. Didn't realise dressing the sledgehammer head would be a concern. How would I go about doing that? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I have my other half that is sometimes a willing volunteer for forging assistance. That sounds like a good way to do it. I don't have a horn though, much less an anvil. I have a sledgehammer head in a log. The other option seems risky and would probably ring even more bells than the hockey puck I've done very little blacksmithing (Even less than my limited bladesmithing). I made a gardening tool for my mum, a set of rebar tongs (that now only serves the purpose of being heated and in turn heating canola oil before a quench) and a sorta kindof a drift. Other than that I have just been trying to make knives (and that one spear). I know my hammer control and skills leave a lot to be desired, but I am working on it, and once i get around to getting some mild steel I would like to try making some hooks and leaves, and perhaps in honour of the previous comment, nutcrackers (really though, i saw a video by Thorbjörn Åhman that was quite inspiring). -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Makes sense. Just an everyday working knife. It is what you use it for i guess. I wish I had a guillotine tool. Alas i try to get by with precise hammer blows (or just hammer blows to be precise) Forging out the bevel on the patang and I ended up with the tang higher than i'd like, and I've been working on another blade this morning where my tang is now riding waaay high and in my effort to correct it it went even higher, and the wrong angle, and banana shaped. Really not a great morning. Never heard of a kiss block before. I think I need to do some more research. Also similar to the sound i made when instinctively grabbing for a falling hot fire brick during this mornings forging session. Also puck in the head? Rings a bell. And here's my blade with out of control tang. Maybe I can draw the tang thinner downwards and grind away on the top? I'm really not sure. On a positive note I'm really happy with the forged out bevels. And tempering in the kitchen oven seems to work fairly well with a bit of extra temperature control. It runs about 20-30 degrees celsius hotter than advertised when it's set to 200 degrees. On the plus side, my tempering oven also makes pizza. (It is cleaner now than in that photo bytheway. I think I turned some rogue chips into charcoal). Also I've been working on giving the pizza blade a hamon the last couple of days. It sure is an art in itself, and I wasn't expecting it to be quite as tricky. I'm getting happy with how it looks now though. Faint as it may be. Had to harden it twice, but still no cracking! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Haha! Yes I must admit I was a bit confused by the abundance of kites, but a parang seems to be a different thing again. I got the spelling from a guy at work, and he is from Bhutan (other spellings include pa-tang and patag. It doesn't seem to be a very well known style of knife, so that probably skews the google a little. And thanks! Quenched without cracking, so I'm stoked! That was quite nerve-racking though. The scream from the brine as i quenched was quite surreal. And yes I had some dilemmas with the tang construction. I've only recently started to forge the whole tang out from the starting stock as opposed to cutting it out, and I seem to be having some trouble forging it into position. This one won't be through-tang construction though, so that should simplify things a little. I've done some sketching, so hopefully I'll have something useful to show for at the end of the day. Now I'll have to see if I managed to get a decent hamon! Aah, see that makes sense. I've seen som many knives referenced as nothing but EDC, and looking back the only thing they had in common was they could be put in a pocket. But ofcourse a big chopper or a dagger could be an EDC if that's what you carry around on a day to day basis. Out of curiosity, do you think my construction falls within the parameters of a certain style? Or is it just a "knife"? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Here's a small knife that I've been working on after normalising last night. I have a thermocouple, but it turns out my forge runs much too hot for any meaningful temperature control, so I just eyeballed the steel colour for four consecutively cooler thermal cycles. Originally I had planned for a much different blade, but the piece of steel I used was not quite right for the job, so I've just freestyle forged it and gave it a full flat grind. Not sure what to call it. Bird and trout? Sloyd? EDC? Whatever it is it was fun. I might just end up breaking it in the next step though, but live and learn, and the best way to learn is to push your limits. The steel is W2, and I'd like to try and give it a hamon, so here it is clay coated and ready for this evenings heat treat. After much reading I have decided to do an interrupted brine quench. (I really cannot justify a big purchase of fast quench oil). Three seconds into brine and then into warm canola oil. Surviving that, and provided it hardens i will take it to the preheated kitchen oven for tempering. And here's what will hopefully become a decently sized Patang: -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

I see. That makes sense why I couldn't find the edit button later on. I did try to edit before that though, but it seems the changes weren't saved in my post. No big deal though. That sounds absolutely fantastic! Thanks! -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

And thank you bytheway! Makes me really happy to hear that! (I tried to edit my original post, but it didn't work for some reason). -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Thanks mate! Really happy to hear that! I've given away most of the things I've made so far, but will make sure to knock up a couple of small knives and drop by your forge the next time I'm up at the Tablelands. I've somehow never managed to make it to Herberton historic village, but that sounds like a great trip and I would love to come by for a chat! And thank you for the offer. I would truly love to have a little bit of wrought iron to work with if you wouldn't mind parting with it (completely understand if you don't though). I saw a wrought iron and steel chisel on here and have seen some laminated wrought iron and steel blades that look absolutely gorgeous. No. I did a fair bit of research beforehand and have rigidised the fibres with aerosil and coated the wool in satanite. Used to work with carbon fibre and doing lots of sanding as well, so I know how nasty fibres and dust can be. I do a good portion of my work with a full face respirator as well. Better look out for my lungs while I have them I figure. That is a good point. My everyday carry sort of knife used to be a Swiss army knife as well. That one is probably gathering dust in a drawer somewhere though. I hope to eventually make a little folder to take its place. For hiking my go to would generally be my Helle futura or a Sami knife. Simply constructed Scandinavian blades with little fuss to them. They don't have a choil, not a ricasso, no guard and have a hidden or through tang construction (which frankly I think are getting an unfair rep for being weak) I find that they are versatile and not very heavy. I think the Rambo style bowies look cool, don't get me wrong. But if you want a knife that can double as an axe, I think you're better off just bringing an axe. -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Yep. This seems like the wrong place to be peddling that sort of stuff. A 1.5 pound knife also seems like an exceedingly poor choice for the outdoors. Currently making a sami knife which at 3mm across the spine should be light and nimble as a carry-on. Speaking of which, here it is rough forged: This will be my first attempt at a through tang knife. So far the plan for handle material is Sovereign wood, antler and copper. If everything goes by plan I will also do my first attempt at a leather sheath for this knife. And here is a spear I am currently making out of leaf spring. I mounted it on a meter of 25 mm dowel for fun, after which my daughter got a hold of it and started swinging it around. The sight of a two year old armed with a spear is an amusing one I'll tell you! I'm working on a socket tool for the spear, but my hammer skills are clearly not up to par,and I've ended up with the dreaded fish mouth. Not a big deal for this tool, but pretty annoying nonetheless. I also picked up this bunch of files and chisels from the scrap yard for eight dollaridoos. The files are currently on their second day of pickling in vinegar, and whichever files come out sharp I will put back to work in their second chance at life. The other ones will become knives in their... second chance at life. -

Justin’s Smithing progression. [PIC heavy]

Bonnskij replied to Justin Topp's topic in Member Projects

I love the leaf hook disc holder. My other half wants me to make backpack hooks for the kids. Maybe I'll try forging them instead of making them out of wood now. What sort of stock did you use for them if you don't mind me asking? -

Bjorn makes sharp things. My beginners log book

Bonnskij replied to Bonnskij's topic in Member Projects

Although not the first knife i started forging. This is the first one i completed. It is a krumkniv (or curved knife) made out of leaf spring and based on archaeological finds from viking age scandinavia: A seax also made out of leaf spring: IMG_1272.MOV Kiridashi (like everything else, also leaf spring) with a sovereign wood saya and ebony pin. And this is the first knife i started forging. A rather chonky kitchen knife with an octogonal wa handle: IMG_1271(1).MOV -

Timing between temper and cryo treatment

Bonnskij replied to Bonnskij's topic in Heat Treating, general discussion

I have a couple of different steels. No point to cryo treating the simple 1084 as far as I can gather. But I have some leaf spring, which (if it's 5160), should benefit. I also have w2, but I don't know if there is a point to cryo treating it or not. Sounds like I have some more reading to do. I suppose the blade might just end up cracking if there's untempered martensite hanging around? The metallurgy of bladesmithing both fascinates and confuses me. Back to the books!