-

Posts

50 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by KingAether

-

Proud to unveil my very humble shop

KingAether replied to KingAether's topic in Building, Designing a Shop

Thanks a lot frosty, i appreciate it. I don't play on locking anything down just yet, will be nice to take it outside in the summer! I just need to find a decent supplier for stock now, thought i had a fabrication place a road away today that would let me take "scrap" but it was a mountain of galvanised rings, so i thanked them and took nothing... I don't like paying for postage costs if i dont have to! -

Proud to unveil my very humble shop

KingAether replied to KingAether's topic in Building, Designing a Shop

Well i might be bias but bigger is always better! -

Ah that rests my mind a little on it being as brittle as i might have worried it was. Maybe mine was later made as i see no clear seams on the face at all, its very clean but i can about see where the face was forge welded on all the way around and it looks as if it was in one piece. #125 as is or marked weight ?

-

Calf leather for an apron ? or not strong enough

KingAether replied to KingAether's topic in Everything Else

Confirms what i thought Kozzy, thank you. We have plenty of chinesium tool stores here, the silverline apron i have is really great for the price, at least once i added a better brace, but you can only expect so much for £$10 free delivery. I know a few leather workers who could probably supply good price hide so ill go that route, just thought i might get away with what i have. -

Proud to unveil my very humble shop

KingAether replied to KingAether's topic in Building, Designing a Shop

Thank you both for the kind words, at least we keep warm in the winter weather ! I probably could have made the bench half the size but that would have been the smart thing to do :L -

As the title states, I'm looking to buy insulating bricks, preferably off the shelf so i can get as few as i like and without the postage doubling the cost. As it stands regardless where i buy from, due to cost or p+p cost i would get 2-3 26's for £20. I have family who travel to Bristol often on the weekend where vitcas only charge 2.60 p/brick but they are closed on the weekend. I have searched a whole bunch but i'm hoping i have missed somewhere, or someone, between there and the coast, maybe a member from here who keeps them for passive income? There is a place about 20 minutes ride away but he wants £10.80 p/brick and i just wont pay that out of principle. Thanks

-

Not sure where else i could post this.. Went on the weekly charity shopping rounds at the weekend and struck it lucky with a few leather jackets that even still had the retail labels, One was extremely expensive RRP and fit perfect so its safe for now but the other i just brought for the material. Its a XXL calfskin leather coat, it wears pretty much like a knee length gown on me when buttoned up but the shoulders are far to wide to work with so it would need modifying at the very least. With that i figured i'd go the whole mile and make a much better apron than the current silverline one i own now but i'm not so sure about the material. Would it be enough to resist the occasional bit of hot metal and grinding or is it to soft for the job, does anyone know? Or maybe i could sell it and buy a hide but i'd rather not the hassle. Thank you

-

Proud to unveil my very humble shop

KingAether replied to KingAether's topic in Building, Designing a Shop

That gave me a good little chuckle! Ill have to pull out the leather scraps tomorrow! -

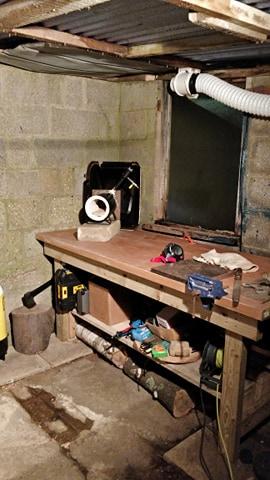

Morning, afternoon or evening! I might ramble a little, i'm rather proud of my humble shop/shed/forge. 10 x 10 x 8 is what i had to work with. Its taken me a few months to get things mostly up and ready, but i'm really proud of what i have and for the first time can show a workable area. When i moved in to my current residence the "shed" was a brick square that i put a tarp over for the first year to keep wood dry but it wasn't enough for a workshop. I started working on giving the square a makeover as soon as i decided my interest in blacksmithing and woodwork was something i was going to take seriously and started looking for an anvil and or lathe.. I found an good deal on an anvil first; lathe soon. My first real wood project since high school shop class 12~ odd years ago was building the door, then the bench, then a roof, i used 90% salvage and scrap wood, only the bench legs and skirts where brought cheap from face book marketplace. Any questions about things due to the quality of the video or any constructive criticism i can take and put to use please fire away, thank you ( i know i have no fire extinguisher, i get payed at midnight and will be ordering one for the morning) https://imgur.com/a/1ZlSTdr <20 second pan around video clip

-

What a lovely pair! I think ill buy some square bar and concrete mix tomorrow to make a portable hardy. Its definitely clear where the original weld happened on the bottom of the heel of mine and seems a weak spot for sure. Further along that it looks yours broke though, just before the hardy hole.

-

Thanks Thomas. The anvil was only out in the wet when i got it home to give it a shower; all nice a snug in a warm shop now Do you have a link to any pictures of your bob-tail? I saw it mentioned in a post someone linked my above too, looks from google like it might be a common fault to powells. Slap my dictionary and call me boring then, Frosty. I'm a big fan of entomology, how and why things work tend to interest me more than the fact they work or what it does

-

I didn't know what was an option, ill have a look at tea'd steel on google and decide then, thanks for the idea

-

I will get to it over the weekend, it couldnt definitely be smoother to use. I'm a bit torn on the rest really, i don't like the faded sky thing it has going on but i a shiny clean steel anything would stand out like a sore thumb given the rest of the shop(inc the roof, door and windows) is built from scrap and salvage. Ill have a think and come post clean up picture when i decide

-

Managed to get this for £10 p/inch last month, need to give the bolt and the handle a bit of love but other than some squeaking and rust friction its in great working order. Only 3" but it was a lot harder to track one down locally than it was the anvil. not sure if i want to just give it some lube where it needs it and let it be or take it all apart and clean it up. The foot is sitting in a 5kg weight that's solid in place

-

Thanks for letting me know about the ampersand, i had a post in the past removed or edited and notification about "not using reply like that" from a mod but i wasn't told what i did wrong so just trying to avoid anymore issues (y) Ill go have a look into the solo hardy's in a minute, it would be nice to keep the plate for chisel work etc and these are the pictures i have available.

-

Irondragon, Thank you for the thread, i did try and find some more info on them as a whole but couldn't find a lot. I could only see that a lot of them are missing the heal so im going to mount a 1" x 12" x 12" plate i have to another stump to use for a hardy. Frosty, It didn't come with the stump, i found one locally for free and chiseled out the anvil shape by hand. Its no longer sat there now, i did try it as i've only 10' x 10' shop space, minus a 7' x 2.5' bench and was getting a lot of condensation due to lack of ventilation but it only took a few days for the weather to tear apart the gazebo so now its back inside all nice and cozy. Got a CO monitor and sorted out the ventilation situation so i'm comfortable working in there now. Ill see what pictures i have and edit them in, lacking that ill get some tomorrow and add to the workshop and vices forums too

-

Took me months to find something local and within my budget but it was worth the wait. #301 John Powell all ready to put in some work

-

Thank you all very much for the replies, taken a load of my mind for sure!

-

Thanks for all the information guys, been offline a little while but i have just read through everything and am taking it in. I tried to move things outside over the week but the set-up didnt work out so im back to trying for good ventilation. I got the extractor out of storage finally yesterday but have been told it might be unusuitable for my use to due how its built posing a risk of sparks and explosions but surely hitting the hot metal in and of itself could also cause a spark? this is what i have, any ideas? The label says it passes 187 m3/h

-

Thank you JHCC, appreciate knowing that!

-

Its gonna take me a while of research to fully understand that, takes me a while on new things due to Aspergers but thank you for the detailed explanation. What is a good example of 38~ CFM in terms of a general appliance ? Large fan, open window, etc? I brought a new drill bit today and drilled 3 x 5 holes in the wall in place of an air brick and plan on checking what exactly it is i have in storage, might have actually been a power unit, not extraction.

-

Thanks for the information and links.. Thankfully no attachments to worry about, its at the end of the garden along a large alleyway behind a supermarket. As it stands i can't afford to do anything fancy.. Or anything much at all right now. Ill keep an eye on the monitor and if needed ill get a fan to put on the floor. I remembered i have a "greenhouse" extraction unit and tubes somewhere in storage, can't remember if its specifically for heat or CO, but im running the light on an extension cable already so not sure about powering it

-

I have read a bunch here, done some searches via google and found conflicting information on CO so i wanted to check so it can be a bit more specific to my work space. I'm a day or two from finishing a 10x10 cinder block shed as a work space and getting started with the forge, while I'm very versed in fire safety and use I've just started to consider ventilation for CO. The shed has a corrugated roof without the foam filler ridges so 1-2cm gaps all along the front and back, a 1/2" gap under the door and the top 2/5 of the door can open separate to keep animals out and one window pane still missing. I'm not to worried about the cold, the garden is fairy wind shielded and in the small space i have the forge will keep it warm. I plan on buying a monitor over the weekend and figuring that out but would like to not have it beep at me of course. Will the mentioned gaps and openings be enough once the last window is in or should i maybe put in slanted slats instead for a consistent, larger opening. Also is CO(2) heavier than oxygen? isn't it? many conflicting posts about that, Considering drilling some holes in a bottom block each side of the shed for vents if it is but would really rather not put my drill or my arm through that job and curious if i should put the monitor at knee height or just chuck it on the bench Thanks in advance for any advice and reading my rambling, im rather excited to start

-

Hello IFL, My name is Liam and i am very new to the craft; full of theory-craft and lacking in practice so far but i want to make sure i'm ready to go when i go! Unfortunately there is nothing in the way of classes, smithing days-out, meets etc in the near by area so i have been learning what i have learned from the wonderful people over on a few (UK) blacksmithing/bladesmithing for begginers groups on social media but find myself coming here more and more lately for the information i need. I have a very all-or-nothing mind-set, blessing and curse, I can learn and progress in anything that interests me at an extreme rate but i can also over-think things at the same extreme. Spending on set up and obsessing over online markets for weeks for good deals because i'm a tight git or reading and learning and questioning for 18 hours straight and forget to eat so you will probably hear from me a lot over the coming months. So far i'm still to start forging anything as I've needed this or that and a place to work that i have been getting together in my own time while i learn from videos and advice over the last few months; In that time i've managed to get: 137kg / 302lb (according to a converter- 2 . 2 . 22) London pattern, nice and flat, no chinked edges, I can make out some marking on it that are the remnants of "WARRANTED" but not sure of the maker 3" leg vice in surprisingly good condition, all original part, no bend in the leg or welded parts Devil forge single burner, 20kg/40lb tank + all the tools i need, hammer, grips, a wrench etc and managed to keep it under £350 in total... so far... Tomorrow i will finish building my shed at the end of the garden and be ready for my first burn so watch this space! Looking foward to meet you all

-

I registered just to say thank you for that correction and information Thomas Powers; i've read a half-dozen threads this evening that have said CO is heavier so pools on the ground and i really didn't want to drill holes into the shed walls. Sorry to jump on a thread but to stop another similar post, a question; Shed is 10x10 breeze block, door has a 1/2" gap at the bottom and i can open the top half of the door separately. Roof is corrugated sheets with no foam ridge filler things. Will that be sufficient or should i replace one of the small windows with angled pallet slats as another venting area?