Bubbadreier

Members-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Bubbadreier

-

What did you do in the shop today?

Bubbadreier replied to Mark Ling's topic in Blacksmithing, General Discussion

I built a JABOD box on legs, started an anvil stand, and I ground off the excess wood from my hammer handle. It has been a busy day in my absolute mess of a garage. Oh I also got the the eBay anvil I ordered before I picked up my peter wright. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

I got the eBay anvil today and I have to say that it seems to be pretty good for the price. It has about a 65% rebound and it definitely rings. Now to find out how to remove the awful blue paint. I attached a couple pictures, cameo by my newly built JABOD box (I might have went too small), and my unfinished anvil stand. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

I will measure when I get home. Thank you for the information! -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

I can't see a clear defined line between the face and the body to measure the thickness of it. I am going to wirewheel the body but leave the face alone, hopefully that will clear it up. How thick should it be? -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Looking into peter wrights, I think you are right. The marking look like this one that I found online. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

I would say that the rebound on straight center is 80% and the edges are about 60%. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

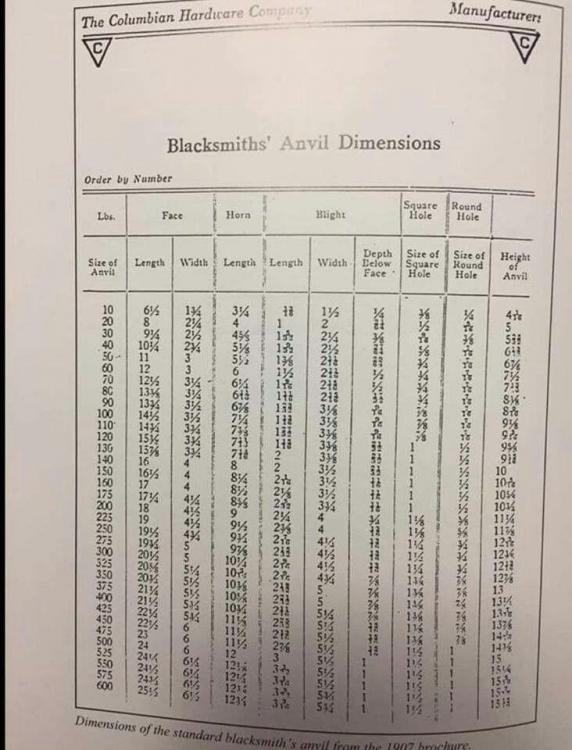

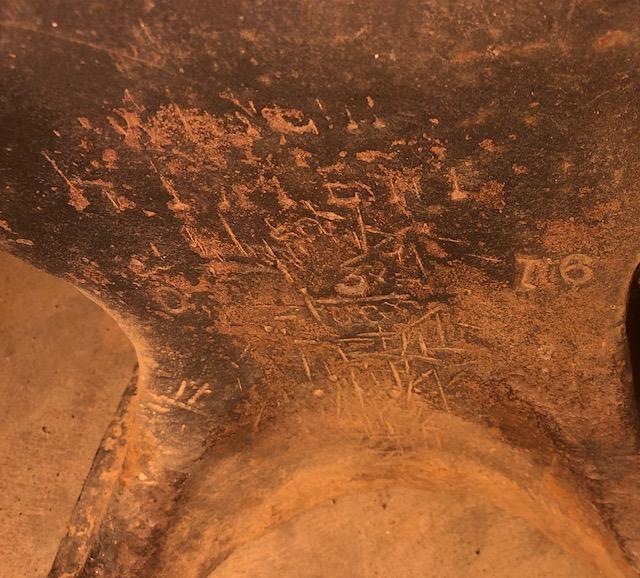

Well wouldn't you know it, the little craigslist ad I put out a few days ago turned up a little gold for me. At least I am going to call it gold, you all might tell me different. I got a call from a gentleman this morning, and he tells me that he saw my ad and he might be able to help me. He has an anvil in his shop that has been there for 20+ years and he has maybe used it twice in that time. He works on machinery for people and some old man had traded a bit of work for it but he just never used it once he got it. He couldn't tell me the weight but he could give me the dimensions. Based on what he told me and comparing it to the below chart, I figured it would be right around 100 pounds. I ask him for pictures but this man said his phone doesn't take pictures. Well I ask what he would take for it and he tells me that the price of these things are pretty high but if I could come up with $250 then it was mine. Well for $250 I thought a 45 minute drive would be worth it, I could still walk away if it was trash. So when I get there he had it pulled out for me and it was covered in cob webs and dirt but it looked pretty darn good. I don't know much about anvils (I still haven't put in the time to learn, shame on me), but I figured it was worth the risk, if anything I can throw it in the flower garden in front of the house. We shook on it and I loaded it up to take it home. Once home I put it on the scale and it comes out to 96 pounds, and for $2.61ish a pound I hope I did pretty good. I will let you guys tell me if I made a mistake. I have included some pictures I took when I got home. I can't read the markings because it looks like there are several different markings and I don't have a clue what I am looking at, but I included a few of those as well. Any help would be appreciated. Now to research how to clean it up! -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Thank you MC Hammer! I went ahead and ordered it, I figured it couldn't hurt for $125 shipped from ebay. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Glenn, I think my Railroad Track is smaller than yours. I could be wrong, I am not the best at judging size from images! I added a couple of pics of mine next to a 2 pound hammer. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Thank you Thomas! I think I am going to go the way Charles suggested and buy a block of steel to use until I decide to buy an actual anvil. Just have to figure out where to buy it! -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Hey Thomas, My ultimate goal is to make tools for other blacksmiths. I know that I am a ways off from that so currently I am just looking to try my hands at leafs, S hooks, and other beginner things. After I am comfortable with the suggested beginner stuff, I would like to try to make a full set of tongs for myself, and then what ever tools i would need to make a hammer, and then make my first hammer and give it to my Dad. From there I just want to make tools for myself and others. -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Glenn, thankfully I am in a position that I could buy a $3000.00 anvil but having had just one short day of hitting metal, I want to make certain the investment will be used by me before I make it! I was just thinking of picking up a farriers anvil because I can get it locally for pretty cheap. (Or so I think. I could be wrong) I really do love the way you put it out there though. It is an investment and cost per use goes down every time you use it and since I will hopefully use it a lot I will quickly "work off" the anvil. But now to go research anvils and all that that entails, I am not even certain what I plan to make yet! Thank you so much for your wisdom! MC Hammer, I definitely need to start the TPAAAT method. I don't know why but for some reason I have this image in my head that anvils are rare in Oklahoma. I know I am wrong and I need to start talking to people! I need to get my Dad on it for me as well. He is a talking and knows everyone. Charles, I would be interested in a Block of Steel to start. I have a couple Railroad pieces but when I stood them up on end I realized how small the face would be and i am not certain my hammer control is that good haha. Anywhere here in the city I should check out for the block of steel? Thank you all for the replies! -

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Thank you Glenn. I walked away, I was just so excited to find an anvil I thought I had to have it! -

Thomaspowers, I haven’t a clue but I am sure I could ask the gentleman that gave it to me. Shows my lack of knowledge, those are things I didn’t even think of! Pnut, very good point. The test another gentleman did to show that it was still soft was to scratch it with the side of a key. Is that considered dead soft?

-

Buy this old champion or new Farriers anvil?

Bubbadreier replied to Bubbadreier's topic in Anvils, Swage Blocks, and Mandrels

Thank you, I just needed someone to tell me to walk away! -

So I just ran across this anvil in an antique shop for $150 (Veterans Day Sale) and it is actual 35 pounds, but it looks like the top is welded on. I was planning on purchasing a farriers anvil next year but I figured this might be worth it? I unfortunately have not looked into anvils much because I didn’t plan on buying one soon and the sale ends in 2 hours. So is this worth it, or let it pass? (200 is normal price that they are asking) sorry if this is the wrong place to ask.

-

Well I went this weekend and I had an absolute blast!! Now I am looking to build a JABOD forge and use the railroad track as an anvil (stood up and mounted). I was gifted a hammer by one of the members but I was told that they didn't quite get the striking face hard and that I would need to harden it. Can I just heat it up with a torch and quench?

-

My dad has some tinnitus as well and he has always been very adamant when we would hunt and go to the range that we wear hear protection. Same with me mowing, if I tried without safety glasses and ear protection he would slap me upside the head! Thankfully I like my eyes and hears how they are so I will follow your advice!

-

Another hobby of mine is shooting, so I do that that taken care of. Thanks for the advice!

-

Thank you guys for the advice. I didn't even think about PPE to be honest, I will definitely get that sorted. I am too tall to have ever had the opportunity to roll my pants up, almost always they are too short. I will do my best to take pictures and post them up!!

-

Hello everyone, I join you having never had the opportunity to actually move metal, but hopefully this weekend I will get to change that. I have been fascinated with the art ever since I was a young child, and I watched the blacksmiths at the Tulsa State Fair back in the early 90s. In the years that followed, I never made the time to learn even when my mother encouraged me to take a class or find a mentor. Now at 30 years old I am finally setting aside the time to learn. I am lucky that I have an active club in my area and on this forum, the Saltfork Craftsmen based here in Oklahoma. This weekend I am joining them for one of their regional meetings and I hope I will get a chance to learn from those that are there. I look forward to learning the craft and being a positive member of the community. Thanks for reading! Let me know if you have any suggestions or questions.