Justin Topp

Members-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Justin Topp

-

Yea that’s true. Some places it’s super expensive. Around here there’s lots of old wrought iron. I’ve spent about 40$ on all my wrought iron. Which is around a ton. Old farms mean lots of scrap which often co contains iron.

-

It’s around 250 lbs so probably for a lot of people! But wrought is common enough here so I doubt it’s worth scrap wrought value here

-

So a few days ago when I got my 6.5” Columbian leg vise I was happy. Well, I’m even more happy now. I bought this 8” leg vise for 125$ today. It is heavy! I put a 4.75” vise next to it for scale

-

Yea many farms had a rivet forge at least and an anvil. But there were a lot of farms without forges and just with an anvil and a leg vise. For beating on stuff and bending things

-

Yikes! I think they are so common because back in the day most farms would have had one. Even farms who were not involved in blacksmithing. And there are tons of old farms around here.

-

I will go ask around when I get a chance. Thank you

-

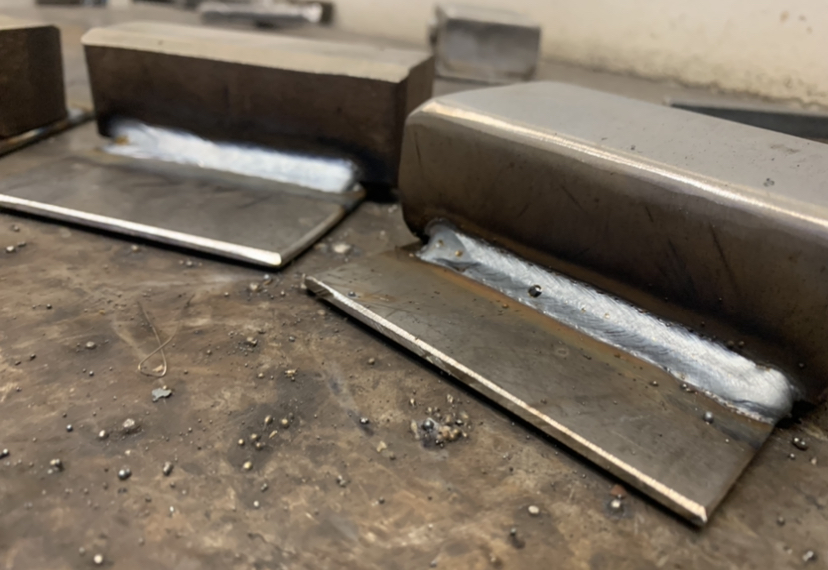

Fair enough, your right Frosty. I’m sorry everyone. I do appreciate the suggestions even if it came off like I didn’t. here’s a hammer forged under the beam hammer. Only hand forging was slight planishing and the drifting, along with the stamping. All the stock prep, fullering, and punching was under the hammer. Each side was fullered in 2 heats.

-

My 5.75” vise has the issue of being too loose haha. When it’s not tightened down I tend to smack myself in the face with the handle. Since it’s really long compared to any other vise I’ve owned. And well oiled so very little resistance. I’d like. Small 3-4” vise for a few reasons. I’ve got plenty of decently sized vises. And no small ones, sometimes I find the jaws are too large and awkward to clamp small things. Plus if I ever need to take it somewhere. Say a craft fair or something it’s a lot easier to move a 30-50 lb vise than a 80-120 lb vise Don’t get me wrong, I’d love an 8” vise haha just a small one is sometimes better for my use.

-

Never thought of an auto thrust bearing. That’s a good idea thanks. I would like a small post vise but they are pretty much unheard of here

-

I’m just spoiled with leg vises haha. They are fairly common around here. The last 4 I got. 4.75” being the smallest and 5.75” being the biggest, only cost 77.50$ total. So that skewed my perspective im sure haha. It’s not uncommon for me to see 5.5-6” for around 100$ it’s more common to see that than 150-200 Got it mounted, but I had to borrow the thrust washer off my smaller vise. Until I can forge a replacement. Also the pipe jaw is much simpler than expected. Some time with an angle grinder will make it easy to replace.

-

I know a guy with a has Cnc mill. So it shouldn’t be too hard to duplicate. Just gotta put it on cad!

-

150$ not a fantastic deal. But not too horribly expensive.

-

New 6.5” Columbian leg vise. This thing is heavy! Missing the thrust washer and a second pipe vise. But I’m planning to make replacements

-

Justin’s Smithing progression. [PIC heavy]

Justin Topp replied to Justin Topp's topic in Member Projects

Accidentally posted here. -

Power hacksaw coolant issues.

Justin Topp replied to Justin Topp's topic in Saws, bandsaws, hack saws, etc

The fluid is new as of a two months ago the hydraulic system seems to work fine The valves it has look like needle valves. -

Power hacksaw coolant issues.

Justin Topp replied to Justin Topp's topic in Saws, bandsaws, hack saws, etc

Now I’m having the issue of my hacksaw has terrible down feed pressure despite the valves being set to the max. Any ideas? -

Power hacksaw coolant issues.

Justin Topp replied to Justin Topp's topic in Saws, bandsaws, hack saws, etc

Turns out all it was, was a little metal bb looking ball of rust. When I blew air though it would move and let air through. And than settle back. Water wasn’t able to push past it. Got it out then the pump worked fantastically. It shot coolant a good 3 feet so I had to shorten the pipe so that it didn’t go so far. The gear pump was fine. So I took it apart for nothing pretty much haha. -

Oil stuff is pretty much all out west. Only things I can get easily from the oil fields is sucker rod and well casing. I’m going to see about contacting a coal mine. See if there’s and scrap, an axle or something. I went to an auction and there was a drag line axle that had to be 12-16” in diameter and a good 8’ long. Huge. Something like that would be fantastic I imagine

-

I looked around for shops that may use large sized stock to no avail. I’m sure they are out there. I wasn’t able to get in contact with the larger shops and the smaller ones don’t deal with steel stock big enough. I’ll try again. Believe me I tried to find some big enough stock but it just wasn’t happening at the time. I believe the local steel supplier sells 1”x6” bar stock. Which was too costly at the time of my build. But I could likely afford fairly soon. That would make a good enough anvil welded vertically I suppose. My apologies if I come off as rude or as if I don’t appreciate your advise. Because I do value your help. Your definitely right that there’s stuff out there. It’s just hard to find sometimes.

-

Power hacksaw coolant issues.

Justin Topp replied to Justin Topp's topic in Saws, bandsaws, hack saws, etc

-

Scrap yards don’t sell to the public here. So I’d have it buy all new metal. A proper sided piece for an anvil for a tire hammer is a 4 hour drive each way. I priced out the anvil and it was about 1200$ Alone. This was before steel prices increased. Plus all the other parts. If I could reasonably build a tire hammer I would.

-

Already putting a bit into savings each week for an Anyang. Similar to the quarter method. But not with physical cash. It will likely be a few years still . But I’m working on it! There are two week sessions in the summer for agriculture research here. Planting and working on those small test plots. They pay rather well. I’m planning on doing at least one to help pay for a larger power hammer

-

Sorry for late response everyone, The bearing thing is a little smoother than what I had other wise. This hits surprisingly hard. About the same as a 40-50 lb tire hammer I’d have to guess. Give or take. id have to estimate cost at around 600-800 using almost all new materials. Definitely can be made cheaper. But a tire hammer would cost about 3500$ to make. Just for the fact I’d have to drive a few hours to get the anvil and a lot of other factors. So far so good for longevity. No issues other than my electric motor appears to need replacing. But it was an old motor that was salvaged so I’m not surprised. I’m sure a tire hammer will outlast this by far. But this should hold up decently well. Easy to repair if there is an issue though. It’s definitely good for what it is. And it’s much faster than hand hammering. That’s for sure. I think I’ll upgrade to a tire hammer eventually. This works for now though. It’s also really easy for anyone to build in a garage. You don’t really need any fancy tools. About the fanciest tool I used was a welder. I cut all the 1” plate for the anvil and ram using a standard 7-1/4” circular saw. Something most people have. I would much rather have an Anyang but those are less budget friendly. Being 16 and only working part time I don’t exactly have as many funds as I’d like. One day I’ll get an Anyang! Overall it’s a great tool that’s a benefit for my productivity. And I look forward to using it more and experimenting with it. Apologies if that was lengthy or hard to read.