-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Greenwood SC

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Thanks again everyone, and thanks Dale, searching for a local blacksmithing guild is something that somehow completely skipped in thought. I'd like to announce side blast charcoal it is! I was just informed a friend of mine has a large amount of land, wood, scrap and metal drums for me to set up charcoal kilns and offered the use of it all so fuel problem solved! I'll be starting work on it all next week!

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

I definately understand there isnt a "one forge to rule them all" haha, just trying to get the most bang for my buck. Technically I think considering my location gas is the smart option but it's not what I want to do. Part of the allure to blacksmith for me is stoking the coals. I'd seen some videos of the washtub forge where they used ash in the mix, that's explains why! What I'm seeing is. and please by all means correct me if I'm wrong, is to pick the design based on the fuel I'll use most often (with the exception of making my bowl using the Adobe/ash to compensate for coal one way or the other). I can use charcoal in a bottom blast and coal in a side blast just not at full efficiency respectively. So if coal is more readily available build bottom blast and if its charcoal build side. As always im super grateful for your quick and informative replies!

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

Thanks for the response about the pipe! Glad to know the zinc can be stripped off. Anyone care to tackle the question of bottom vs side blast for both coal AND charcoal? I just found I cant buy coal by the bag but rather by the pallet at 6$ per bag. I figure 1600lbs of coal would keep the forge running for quite some time but in the off chance I cant get a shipment (and to work with until the first one arives) I'd like to be able to use charcoal as well if possible. Note: sorry if I come across as though I'm flip flopping. I'm just trying to weigh all options before construction and asking questions as new info becomes available or brings concerns to my attention

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

New question as well, can i use galvanized pipe for the tuyere? I thought it put off fumes but I cant find anything else... if not what are my alternatives?

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

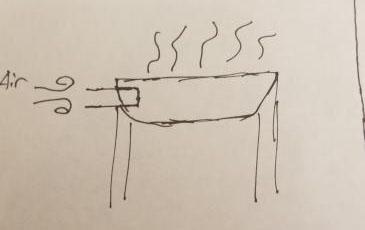

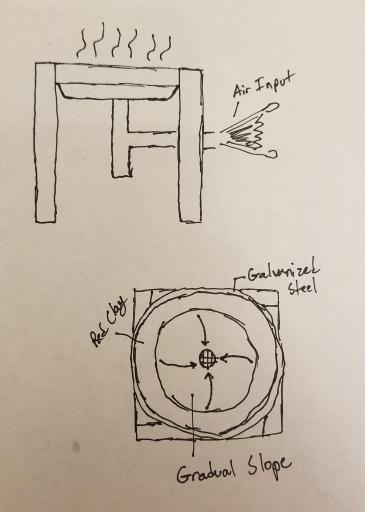

I've noticed more and more wrong with it as I learn but i still like the image haha

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

I cannot say thank you enough! You cleared up a lot of things for me and answered all of my questions perfectly! I'm going to get started today and post pictures. the hood i referred to adding was that of a furnace style vs a chimney Additionally, i'm aware the clay will vitrify over time but im assuming this can be remedied by cleaning and replacing the clay? One more question. I'm on my way to see if my local tractor supply can have rice coal shipped in for me since I'm 90% certain I saw you say that would work well and at 6$ for 40lbs would be far more readily available than making charcoal once a month at my parents place. That said, what would be best if I wanted to be able to interchange between coal and charcoal? Side or bottom blast? And is that even a good idea (provided I stored and used them separately?)

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

@Charles R. Stevens thank you! Your Jabod threads were where a lot of my info came from but i feel even after about 3 reads I'm still picking up new things out of them I missed previously, but i really appreciate the measurements because I read your brief history of sideblasts atleast 5 times and feel I'm too new to the hobby to understand that chart! That's exactly what I needed. Sorry if I came across as just begging for info, I'm just not certain how to articulate my questions just yet! Heck, before reading that brief history I didnt even know what a tuyere was, I just called it the airhole like uncultured swine. Reviewing your jabod articles, brings 2 specific questions to mind though. The first is clarification in something frosty said earlier about not saturating the clay too much. The clay in your photos looks quite wet and sculpted (hence why i thought that i was supposed to essentially make putty out of it) am I thinking too far in extremes? Meaning did i go from planning to use too much water to too little in my mix. 2nd, i notice in all your build photos you have a few fire bricks stacked on one side of the fire. Is this necessary or does it serve a specific purpose? (bonus question) would building a "hood " into my forge over the heat source help in charcoal efficiency?

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

@Charles R. Stevensevery thread I've posted (and quite a few that I've read) has pointed to you for information. I'd love some advice on measurements especially on tuyere pipe diameter, location etc. The things an amateur like me wouldn't know to maximize the use of my charcoal. @Frosty Thanks! I thought I was supposed to make it into like a putty so I'm glad you mentioned that!

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

Thanks! So no issues with using the galvanized pan as a base? I didnt expect there to be hence why I'd went with it but want to be certain before buying it. It's just the 4$ it costs is way less than what id spend on wood to make it

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

Charcoal. I'd prefer coal but see nowhere I cacan get it for less than $1.25 lb and that's out of my budget right now. So instead im going to set up a charcoal kiln at my parents house since they live out in the country. Is this what you're suggesting?

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

Lupercal changed their profile photo

-

Hello again everyone! I've been learning a lot from these forums and everyone has been great so far. I think I'm ready to attempt making my first forge. Its not exactly what I want but I live in city limits and hope to move in the relatively near future so u opted to build convenient over desire. I've read must be 2 dozen threads on here alone but still feel I'm just grasping at the concepts so consider this a wide open invitation for constructive criticism as I wont he starting construction until i see some green lights from you guys. So heres the plan: I think the JABOD is the best foundation for me right now as good red clay is abundant for me to work with. I've got a 4 inch deep, 24 inch diameter galvanized steel pan I plan to line with that clay about 2 inches thick and sloping down into the tuyere. The tuyere will be a 1.5 inch hole drilled out of the bottom into a likewise diameter steel pipe that T sections off for the airflow to come in from the side and the debris to fall straight down. I've seen a lot of folks mention kitty litter instead of clay but is one better than the other or is it just availability? I'm not 100% sure i used the correct terms anand please forgive spelling errors as this was typed on my phone. I look forward to hearing from you! PS. I finally updated my profile to include location! Link to a tub that is close to the one I'm looking at. 16.5 x 16.5 x 7.5 inches and holds 3 gallons

- 25 replies

-

- feedback

- solid fuel forge

-

(and 2 more)

Tagged with:

-

Thanks! I'm liking the sound fo the Asian box bellows and need to look into that. In regards to my terminology, I think I'd better draw up my plans and post them here to know not only if my design will work but also what it's actually called haha.

-

Hey all! So I got some awesome advice regarding side blast forges ans have settled on a design for that (will post pics and updates later) but now I'm looking at bellows. I don't want to use a blower and would prefer a traditional bellows but havent really found any good info online about materials for making them. What are some alternatives to leather that I can use to make some large bellows for my furnace?

-

Thanks guys! I'll start looking into side last forges.

-

So I've just started blacksmithing. Currently I've been practicing hammer control on making miniature swords out of old nails using a blowtorch for heating but I'm really looking to get an actual coal fire going. I've seen a lot of posts, videos. etc about ways to go about this but they all have varying concerns for me and so I decided to make my own post so you guys can help me decide how to go about this. I'd prefer to go "old school " where possible as a large part of learning to Smith is the medieval history aspect so I want to do coal and manual bellows. I'd seen some stuff that i can use clay? I live in an area that red clay is abundant. Could I form and shape an "oven" forge out of red clay? Any suggestions are welcome and I'll reply with my concerns if any so you can help me decide. Thanks!