-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Donal Harris

-

Stock for making axes?

Donal Harris replied to Conrad.blacksmithing's topic in Axes, Hatchets, Hawks, Choppers, etc

Those I have tried are brittle. -

Stock for making axes?

Donal Harris replied to Conrad.blacksmithing's topic in Axes, Hatchets, Hawks, Choppers, etc

Brent took a standard ash handle and cut it down and reshaped it. I could do as you suggest and plane it down and build it back up after shortening it, but I want to change the head profile a bit. What I wanted to make was something like his “Middle of Nowhere” pattern. I really like it because it has clean and almost elegant lines. I don’t like most other patterns. I couldn’t describe to him exactly what it is I don’t like about them except to say they look like “sporting women”. I believe that is a family friendly term for what I actually said. The lugs are big and exaggerated. I want to shave down the beard just a bit to make it easier to get my hand around. As for the handle, I want it about 2” shorter, thinner, and made of bois d’arc. -

Stock for making axes?

Donal Harris replied to Conrad.blacksmithing's topic in Axes, Hatchets, Hawks, Choppers, etc

Terminal swell. Otherwise I will shorten it. I may just do a new handle out of some bois d’arc I cut a month ago. Maybe next fall. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Great Man o’ War and angel. The angel I may copy if you don’t mind. Your dog looks like he is ready for you to stop playing in the shop and give him/her some attention I agree about the leaves. Chisel is too sharp. -

Many or most towns have a brush pile. Ours sets logs to the side for anyone who wants them for free. That is where I get my stumps and smoker wood.

-

If you happen to run across an inexpensive electric motor suitable for running a hand cranked blower, maybe you could hook me up. I have two blowers and am interested in trying to convert one of them to be belt driven. Assuming I could drop the speed down.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Stock for making axes?

Donal Harris replied to Conrad.blacksmithing's topic in Axes, Hatchets, Hawks, Choppers, etc

This is the camp axe I forged with the help of Brent Bailey. It is pretty sweet. Edge stays sharp for a long time. Fairly light and easy to use. Only thing I wish I had done differently was make the handle about 2 inches shorter. it was made from a 5” piece of the thicker bottom spring from a set of springs from an old Ford F-250. I love it. I named it Rush Creek. It was built Ford Tough! -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Still have to put a hook on it for a hanger, it it is what it is. Rather crude. I coated it with bees wax and BLO. Later I buy some clear coat so my daughter will not have to oil it. The next one will be better. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Not sure. I use either vinegar and H2O2 or muriatic acid or muriatic acid and H2O2 because that is what I have. I usually use vinegar and H2O2 because I don’t have to worry as much about the timing and it is easier to handle. My problem here is the copper. Vinegar and H2O2 eats copper rapidly. I wanted to use smaller wire, but snapped the bit. Then snapped the next bit and the next. I should have used the drill press instead of a hand drill. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

I’ve never seen a basket twist like that before. I can see it would be nice on a curtain rod too. Frazier, how did you get the fullering so even? Still not finished with it. The etching didn’t go well. I soaked it in muriatic acid for 26 minutes, then another 26 minutes, then another 26. Still not etched well. Added hydrogen peroxide and soaked it for 26 minutes, and then again. Much of the grain is really just scratches from the grinder and sand paper. Tonight I may take it down to 1000 grit and soak it for 2 hours. Looking at it I am reminded of the cups and plates my daughters would make me in preschool. -

Machines? What sort? Blacksmithing gods? You must not have television.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Not finished with it yet, but this is what I have so far. I still have to finish adding the rest of the copper ornaments, etch in muriatic acid, and then coat it with BLO and bees wax. It is possibly a little too heavy. I may have to grind away part of the back. -

Fire pot dimensions for coal forge

Donal Harris replied to Donal Harris's topic in Solid Fuel Forges

How has that worked out? Mine is simply too deep. I’ve considered clay, but I am likely going to just make a new pot with a “ball” clinker breaker. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

I don’t really punch and drift enough holes yet to justify anything more than the coil spring and other automotive scrap I currently use, but I have wanted to try some H13 or S7. I was just not wanting to waste my money on something that would be impossible to work by hand after it cools. Now that I know this doesn’t happen, I may try some, that and Atlantic 33 which Brent Bailey recommends. Evidently it doesn’t need to be tempered. Just now I was curious about the spelling of H13, meaning H13, H-13, or H 13. After Googling it, I found it spelled as both H13 or H-13. I suppose it is however one wants to spell it. I also found I could purchase H13 from Walmart with free shipping. What is up with that? -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

It is 3.88889 degrees Celsius today. SI units are Ok for most things, but lousy for temperature and club selection in golf. 39 degrees is bloody cold. 3.88889 degrees Celsius is the same uncomfortably cold as 39, but sounds much worse. 9 degrees C sounds just as cold, but really isn’t. Anyway, what I plan to do outside at the forge today is make a few ornaments. If they don’t turn out terrible, I will post pictures. I am curious about that S7 (H13 also) If you buy it in an annealed state and heat it up to cut it, wouldn’t it be hard to forge later after it has cooled, even when brought back up to a forging temp? I have never used it, mainly because I have no press or power hammer, but also because I thought I would have to keep it hot the entire time I was working it. It is very rare that I would totally finish something in a single session. I get bored after a bit and do a little on other things. -

Stock for making axes?

Donal Harris replied to Conrad.blacksmithing's topic in Axes, Hatchets, Hawks, Choppers, etc

Me too. That spring clamp looks like it would be very useful for many other things. I am borrowing the idea. -

That sounded like a good idea. I have one I made from a bolt used with the fish plates, but it is too light to use for more than thin copper. The pin piece I have weighs 2.248 pounds after I smoothed the dome and ground down the other end to eliminate any visible cracks. I should be able to draw it out a bit, then punch and drift the eye without it dropping in weight too much.

-

Very old thread, but thought it could use a photo. This is the top 3.5” - 4” of a knuckle pivot pin. It sparks as if it is medium carbon. I have no real plans to do anything more than use it as a paperweight. I had thought I might make a Hardy tool from it.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

I pity the SCABA member who drew my chain and hook at a meeting. This is my first, and so far, my last attempt. Yours look like factory made links in comparison. -

It was a pleasant 22.2 degrees Celsius here this weekend. A bit windy last night when a cold front came through. But the warm weather will be back in a couple of days.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Why haven’t you beefed up the circuits? Are you not an Oklahoman? My dad began showing me how to do plumbing and electrical stuff when I was a little kid. I thought all of us grew up that way. I assume it is where you do small engine repair work? If so, you could deduct it as a business expense. -

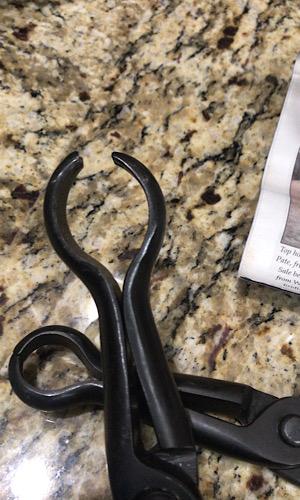

Both of them work well for holding things. But after using the larger of the two today I am not totally thrilled with how they open. They are a little stiff. This makes it harder to do things like take a cube and work it into a ball. For that I need to adjust the piece a lot. When I have trouble opening the jaws I waste heat.

-

Actually came in a couple of days ago, but who’s counting. Two pairs of pickup tongs from on line, 1” and 1 1/2”. They were packaged along with some fire starting material at no extra charge. The 1” seems to be good. The 1 1/2” jaw tips look to be a little off. Haven’t been able to use them yet, but they are lightweight and springy. Shipping was a little slow, but that is outside of their control. What is in their control is response to emails. They did not respond to the three I sent.

-

This is the Hardy stem on my guillotine tool. The base is mild steel. This stem is just a piece of mystery steel I had in the pile which was pretty close to the right size for the hole. It is carbon steel of some sort. I used 6011 and did not preheat the carbon steel first, which I learned later is something you should do prior to welding carbon steel. The weld held for about two years or so, but I can see from the rust around where it broke, it had been cracked for quite some time. Not knowing exactly the type of steel means no one can do more than just guess, but what things could I have done to give it a better chance of not failing? The most obvious to me would have been mild square bar, and that is what I will go with when adding a stem back. I have several sticks of various sizes of mild square bar now. Would 7018 have been a better rod to use? Dad has both 7018 and 6011, but I’ve only ever used the 6011. It seems to be the welding rod equivalent of duct tape.