-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Donal Harris

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

That is what I expected. I just wanted to make sure you weren’t also able to make all the old time clock gears and springs. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

What will you use for the clock’s internal workings? -

Nope, but I did tell her just the other day the thing is a booger to start unless you follow the instructions on the saw exactly. Then it fires up easy every time. I should be good though. I think she had drifted off to her happy place. She likely never heard a word of it.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

I used the other side, which is more of a coarse, double cut file. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

I like the look of the doors as well. Still a little sad about the weld on one face failing on my hammer build attempt. Decided to start on the drift I will need for it at some point. Mystery steel. Know only that it was some sort of wrench for very large lug nuts. Learned 3 things: avoiding fish lipping is harder on larger stock, the steel cracks if I try to forge it when not almost yellow, and hot rasping is quite calming. I had never done hot rasping before. I have one of my great granddad’s rasps. Finally decided to pull it out and give it a try. The sensation is quite unlike what I expected. It was quiet and the steel was soft. It actually made me not nearly as upset about the cracks as I had first been. Very relaxing. -

She still hasn’t agreed. I just hope she does before the 54 he will be receiving from the foundry in May have been sold. Unlike what someone above said in 2018, he responded to me very quickly. Within a day. If she doesn’t, it would likely be for the best anyway. I need a grinder much more and a motor and VFD will not be cheap, even those which have been rebuilt or refurbished. I have a perfectly serviceable anvil for someone who is not planning to feed the family with it. 97 lbs is large enough for the stock I use most. The edges have been abused, but a Hardy tool would fix that. Plus, being a Mousehole, the King of all Anvils, it has plenty of rebound and a huge sweet spot.

-

It would be too short. My feet wouldn’t fit.

-

Not “new to me”. New new. Maybe I should have said new Fontanini anvil. It will be left rough, but the discount for that just about covers shipping.

-

Assuming my wife allows it, I will have a new, 250 lb Rat Hole Forge anvil some time in May. She gave me the evil eye when I first brought up the subject. I am not entirely sure why. It is essentially free-ish. I took half of the first stimulus check and opened a RobinHood account. I thought my arguments as to why I need it (despite it being a hobby and already owning a small Mousehole) were pretty solid. She didn’t seem to buy into my logic. But thanks to a thread on IFI about how to move a 400+ lb anvil, I am able to counter at least one of her counter arguments. My only concern about it is the hardness of the face, but Nimba anvils seem to have the same hardness values.

-

I believe I will try to make a steel faced WI hammer

Donal Harris replied to Donal Harris's topic in Hand Hammers

I just looked back at the photos as well. It is visible in two of them. I burnt and cracked that face pretty badly on the forth try. I was well and truly miffed by then. Normally I am able to keep stupid away, but this time I just let my anger take over. I still have about three feet of that thick spring steel and enough WI to fail at this many, many more times. I also have several rail anchors. I have considered trying using some of that for a face to see if it might be easier to forge weld. -

Totally did not expect people here to have to Google “cannon bone.” My idiot baby brother, sure. Same with my son in law. There is no meat on them, so they just get tossed. This past season I texted my son in law twice to remind him while he was hunting in Arkansas. Even sent him a screenshot of a deer skeleton with the bones circled in red with arrows pointing to them and a note saying “tell the processor you want these bones back.” Still he forgot.

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Man, you are one heck of an artist. -

I want to make a frontier style knife some day. The cannon bone is for the handle. I really liked the work Gib Guignard and Chuck Burrows did. There is no way I could even come close to what they were able to produce, but I would like to try nonetheless. Totally missed the “spoon” thing. LOL

-

I believe I will try to make a steel faced WI hammer

Donal Harris replied to Donal Harris's topic in Hand Hammers

I was going to make the drift this morning, but while waiting on the fire to get hot I took a look at the areas I had fullered and filed down on the hammer. I am not sure how I missed it the other day, but there was a hole. I shaved down a toothpick and the hole went almost all the way to the other side. I got the angle grinder out and cut down till the weld was solid. The face was totally non welded except for about 3/8” all around. I tried four times but couldn’t get the weld to take. The other face seems to be welded. Rather than a rounding hammer, I will just replace some of the lost mass with more WI and shoot for a cross peen. -

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice hinges. -

I’ve been trying for the past three seasons to get a couple of cannon bones. Everyone forgets. Many of them don’t even know what a cannon bone is. I have a couple of sheds given to me by the neighbor down the road. He has a tub of them. Kentucky doesn’t have a commercial hunting industry. That surprises me. Even Oklahoma has commercial hunting.

-

It will file, but only barely. And I am terribad at filing. What little steel I removed this morning made it worse. I think I will wait till we have meetings again and attend a SW Region meeting. It is often at our president’s shop. He is pretty skilled and may know a machinist who can mill the faces. Or text Byron Doner, one of our directors and former longtime President, and ask him who I might pay to mill them. He would know someone. In the meantime I will just use it as is and maybe cut some covers from scrap copper pipe. I will need them eventually sometime anyway. As for taking a hacksaw to it, I am sure that would work, but jeez!

-

I think one side likely will be and it is not the side I would have expected to be the hardest to grind. The welded side seemed to be harder. I will run a file over the jaws tomorrow to check if they are too hard to file. Thanks.

-

I am not sure I made it any better. I took a shade too much at the top and now instead of convex it is rippled. It was maddening. Take a little here and now it is low here. Fix that peak and it just moved somewhere else. If we ever get to begin having local meetings again, I may ask if anyone knows of a machinist who is also a blacksmith or at least knows about blacksmithing tools. Speaking of blacksmithing tools, more than one of mine has the initials of a prior owner punched into it. My vise was owned by C.P.M. I assume that is the initials of the blacksmith, farmer, or rancher who owned it. (Being a nerd CPM meant something entirely different than someone’s initials when I first saw them.)

-

We used a grinder. Tomorrow I will reassemble it to see how well we did. Probably wire cup it to remove the rust again, but this time protect it with BLO, followed by more BLO periodically. I should paint it, but just really prefer to see it and feel it and not the paint. Would a waxed canvas cover help?

-

Once I have built it, that is what I will do.

-

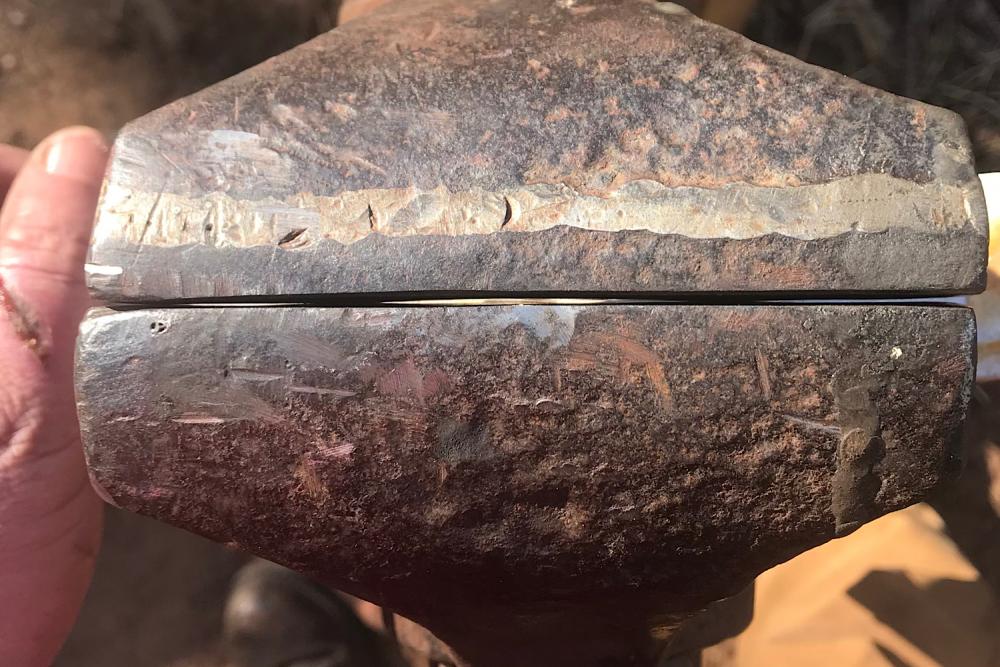

I purchased this SCABA swage block a few years ago. Rather than wait on a new shipment, I purchased this one even though the two halves of the mold were misaligned. How can I clean it up? Someone told me a Dremel tool but that would take way to many bits. I tried an angle grinder, but that was difficult to control.

-

I believe I will try to make a steel faced WI hammer

Donal Harris replied to Donal Harris's topic in Hand Hammers

Since the other hammer I was making had its face pop off during forging, I was concerned the welds on this one were just as poor. I didn’t want to go through all the work of punching the eye only to have the faces pop off during fullering. So I filed them down till I could see not even a hint of a weld line and then beat the heck out of them in my spring fullering tool. I was pleasantly surprised when they stayed on.