-

Posts

2,539 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by BillyBones

-

The temp was at most 100F. The reamer is in a floating holder. I am also not the one who tooled up the job and have no clue as to why they chose a reamer. I ended up using a 9mm drill (.3543") ground down slightly to about .354" in a rigid holder and cut 1000+ parts after lunch. This job is on a Davenport 5 spindle screw machine. Notoriously difficult to get reamers to cut worth a ...

-

I have lived in many places in my life but none long enough to become a local except for where i live now. I spent my formidable years here, moved away to other places, and then came back. I remember me and my freinds always saying that first chance we got we were leaving this place, and we all did. With just a couple exceptions we all also moved back and stayed. Since we are talking about relocating a bit of relocating music

-

You ever see something so obvious but it takes you years to realize it? I just had that moment. Of all the years that i have worked with metal from blacksmithing to machining i just now put the 2 and 2 together that tenoning dies are closed die. Doh... I just always thought of closed die as something on an industrial scale with huge presses and the like. Frosty, now that i see it as closed die you are absolutely correct, you have to have that relief. I use my monkey tool as a gauge, once it fits inside that i am pretty good to go. Mentioning holes and a bit off subject, i spent 6 hours today trying to get a reamer to cut within tolerance. I got .3535"-.3565" And with a .3545" reamer it would cut both undersize and over sized. Using an 11/32" drill (~.344") as a pilot. Bout pulled my hair out.

-

My guess would be 2 pieces.

-

blacksmiths in bloomdale ohio

BillyBones replied to alexander gibson forge's topic in Everything Else

Thank you, we really need a blush emoji thing. -

blacksmiths in bloomdale ohio

BillyBones replied to alexander gibson forge's topic in Everything Else

Same here as well. If you are ever near Dayton, or just want to make a road trip, and want to mash some metal give me a holler. I aint no teacher but have learned a few tricks in my time. May also want to look into ABANA and their online classes. -

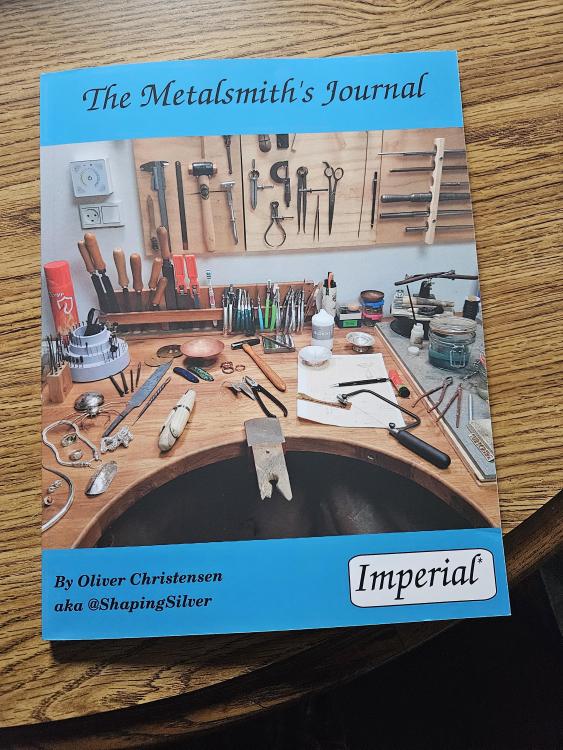

Frosty, i saw Tjorborn Ahmen using one in his latest video. He did make a pendent though in that video so still jewelry. That made me look into it. Even though it is not specifically geared toward the blacksmith for $8 i find it worth the investment myself.

-

blacksmiths in bloomdale ohio

BillyBones replied to alexander gibson forge's topic in Everything Else

I had to look up Bloomdale, lived in Ohio most my life and that is a new one to me. Have you tried NW Ohio blacksmiths? -

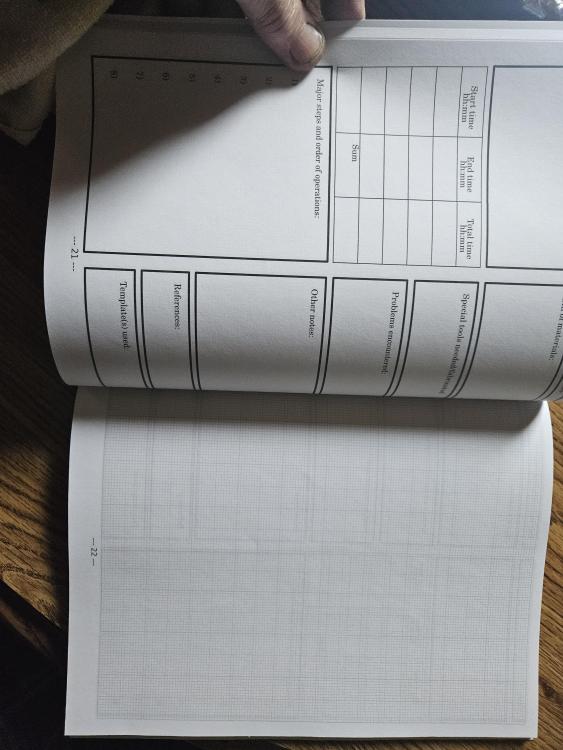

Frosty, it was about $8. Off amazon. I really, really do not like to use that website but sometimes you just have to. There is also a table of contents that you fill out so you know what is on each page. As well tap and die charts. I am also pretty sure it is geared towards jewelry makers cuase there is also a conversion chart for ring sizes from country to country and a AWG chart.

-

Mail just came. This should organize ideas much better than random scraps of paper stuck in a drawer. This one is in inches but they do have metric available.

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

MacLeod, I have been trying to figure out how to make them out of pipe so that i can run wire through them to get an electric light. I do not want to weld them or I want to have at least the appearance of traditional joinery. I tried an LED solar light, it was nice for about a month then it just kind of piddled out. I got that same dark problem but it is the front of my house. When i bought the house i did not notice that it did not have a single outside light. So first thing i did was hang a nice HPS lamp outside my shop. Lights the backyard up nicely but the front is still dark. We use the back as the main entrance though so for me it is no big deal. The wife however likes to walk to work a lot and she does not get home till after dark and wants something to light up the front of the house. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Das. There comes a time when you just have to stop rather than do more damage. I have been off work since Wed. and have put in a good 35 hours in the shop, so it has been a good weekend. I also forgot till you posted, but i love that bearing snowman. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods, maybe i missed it, but how did you do the sockets for the middle bar? Christmas fast approaching. Seem to be running out of time but got another book stand made and 2 outdoor sconces. Yes the one sconce needs a bit of tweaking on the basket. Dropped my form tool i was using and it rolled under my toolbox, my back hurts, my feet hurt, i was getting frustrated, a few bad words and i called it a day. Also on todays episode of need a tool, make a tool. Was trying something new today and it was small and finicky. I did not have any way to hold it very well so i made 2 sets of small light duty tongs. Made of 3/8" round and they hold surprisingly well for their size. Top ones are set at 1/4" bottom at 1/8". -

When i bought this house one of my preconditions was an out building to use as a shop. A garage would be fine as long as it was not attached to the house. If something like a fire were to happen i would rather lose just the garage than both the house and garage. This place has a 1 car garage and a 30x30 barn. The garage is one of those small 1950's type that is actually to small for my truck. So the garage became my workshop and the barn my garage. My dad picked up one of those prefab sheds a few years back for $100 from a moving company. Some moving companies have warehouses to store people stuff in. Sometimes that stuff never gets claimed so the company will sell it. You can also pick up a conex, used, for less than $2,000 if that is in your budget. Congrats on the new home though. I, like everyone else would say wrong time to buy, but if the price is right and you can agree on terms to your liking, more power to ya.

-

I may have made a mistake

BillyBones replied to Jason L's topic in Blacksmithing, General Discussion

When we made spud guns we used starting fluid, no need to shake since it was an aerosol. Small little hole just big enough to spray into and a BBQ igniter. How about a jai alai mitt or whatever they are called to throw the ball with? Maybe a catapult or a ballista? It is also quite easy to build a pitching machine, an old riding mower wheel attached to an electric motor and a trough to funnel the ball. We went through a sling making phase as well when i was a kid. I was never much good with one but they are fun. We also tried the Atlatl, they were ok but did not work as expected so we gave up on them. Had we kept trying we provably would have gotten them worked out. But you know young teenagers, lost interest and moved on to the next implement of destruction. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Tim, need a tool, make a tool. Like that swage block. Chad, very nice indeed. My grandfather was a cabinet maker, never caught on with me though. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

I think that may translate to the American saying "I hate Monday" Just always keep in mind that if it were not for Monday then Tuesday would the hard day. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Well it is almost Thanksgiving so it is time to start getting geared up for Christmas. My mom and my aunt are quilters and like to cook. So this year they are getting book stands, or i suppose you could use it to hold an i-pad. No, i still have not cleaned my bench off, but at least i can see part of the top. -

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Hondo, is the copper visible along the spine and underside of the handle as well? If so i am thinking a faux cap on the but end by bending the copper like the faux guard would look quite nice as well. I prefer drop point rather than up swept, just my taste, nice job regardless. Alexandr, i do not envy your driving spikes into frozen ground. -

I may have made a mistake

BillyBones replied to Jason L's topic in Blacksmithing, General Discussion

I did not have a "job" back then but i did do things like mow grass, weed gardens, shovel snow, rake leaves, whet ever. My dad actually bought my first car for me, that Nova, when i was 13. I still think it was becuase he wanted it. My dad back in the late 60's and through the 70's drag raced. Most of the cars him and his friends had they built. It had been about 5 years since he had built a car so i think that is why he actually bought it. 1983, that was the year i became a professional mechanic. The first time i had ever been paid to work on a car. My dad's freind let me put brakes on his car. My dad of course supervised and made sure i did it right but i did all the work and got paid... so i could put that money into "my" car. We tore that car down, did the body work, had a bit of rust here and there. We built the engine, somewhere around 4 maybe 450HP, locker rear diff, then jacked it up in the front, a bit in the back, set of Hookers with cherry bombs and nothing after. As a teenager i ran a 13 flat in the 1/4 my best, my dad never drove it but i am sure he could have gotten into the 12's. Anyway when i turned 16 my dad gave me 3 boxes. 1 had a Pioneer radio with cassette player and 2 6x9"s, another had the keys to the car, and the third was full of receipts. He said that is how much you owe me for the money "we" put into your car. So i got my first real job and paid him what i could. As i have become older i do not think it was so much that i paid him back but that i went to work and learned what responsibility is. My dad and i still work on cars together. He turned 74 this year but still gets under the hood. Right now we have a '72 Monte, it is in a shop for paint over the winter though. I will have to post pics when we get it back from paint. We do not build drag cars anymore just mostly clean them up and dress them up. Then find something else someone is willing to trade us for, or sell this one and find another project. -

I can think of nothing on a car, especially modern cars, that is heavy and big enough to use. Maybe the rear axle of a large truck. What i would do is start by looking at the improvised anvil thread for ideas on what to look for. Like fork lift tines or the counter weight. Also just describe to the people what you are looking for. You may also try your local steel supplier. I bought a 6"x6" cube of 4140 as a drop iirc ~$10, that was 4 or 5 years ago so may be a bit more expensive. I use it on the floor to upset long bars or set it on my forge to weld small stuff.

-

I may have made a mistake

BillyBones replied to Jason L's topic in Blacksmithing, General Discussion

When we bought the house here a couple years back there was a washer and dryer left in the basement. I had just about a year earlier bought the wife a brand new set and she did not trust the dryer i "scrapped" them. That is several square feet of sheet metal i was not about to just throw away. It is kind of thin as well but i use it to make ladles with or wax catchers on candle holders. Small stuff like that. I can usually work it cold as well. I tried a piece for a fire place shovel but to me it just seemed to thin and it may have worked now but down the road i do not think it would have held up. I remember those days of the banana seat and puffy black Huffy seats. Having to hold the front wheel between your legs and straightening the handle bars. Ooooohh, the plastic 5 spoke rims. If you were fancy you had pads as well. Me and my freinds would go and find old bikes at garage sales and stuff then build our own. Fun times back in those days. Then i got a drivers license and a 1970 Nova SS. -

I may have made a mistake

BillyBones replied to Jason L's topic in Blacksmithing, General Discussion

The place where my wife works has a huge parking lot. When i would pick her up from work it would be late and no one in said parking lot. So of course that meant doing doughnuts in the snow and rain. Quite fun. Then i got a new truck and i turn off the traction control and the stabilitrak but i can only get about 1 1/2 good spin. Me and my ex-wife used to sit in candle light a lot. If a Betty Lamp is what i am thinking it is, we made them out of mason jars when i was kid. Fill the jar about 1/4 way full of lamp oil. Cut a wick about half the depth, a bit less, of the jar. Take a piece of wire and make a spiral, pull it up so the spiral is a cone and the top small enough to hold the wick. Put the wick and holder in the oil in the jar. You could make a hanger or sconce to hold it, or just set it on a flat surface.