mpc

-

Posts

74 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by mpc

-

-

It’s a 3 burner propane. I don’t know how old the lining is, what it may have been treated with, or how thick it was (originally).

I’ve been futzing with the intakes, putting bricks in front of the door, and stuff to get it hotter but I’m basically just taking stabs in the dark.

I didn’t build the forge, I got it for a song from some kid who was moving. I want to pull out the liner and do the insulation again but I never seem to have time to chase that pig.

-

This is my anvil and base. The base is a big ol’ pine log. Pine was not my first choice (or 2nd or 3rd) but when you live in an area with no trees, you take what you can get.

As expected, the log is splitting. I’m wondering if it would be worth it to try to forge some straps to go around the log to keep it together.

How would you go about forging such a thing? I was thinking I’d put a 90° bend about an inch from each end of a long piece of 1” wide weld steel, drill holes in the 1” tabs, bang the weld steel to shape right on the log, then tighten it down with a bolt through the holes.

-

This was cleaned up REALLY well, placed in the forge and heated to a dark red, fluxed (Borax), heated more, fluxed again, then left to heat until it looked (to me) like a bright yellow. Then I banged on it enough to make sure both sides were making good contact.

I let it cool to black, then I put it in some water (so I could touch it), ground the edges to see how it looked, and then tested it by banging a screwdriver into the V to see how quick it would split.

I’ve had a pistachio give me more trouble coming apart than this.

-

Thanks!

What do you think, thin it out to about 1/2 of that?

-

-

-

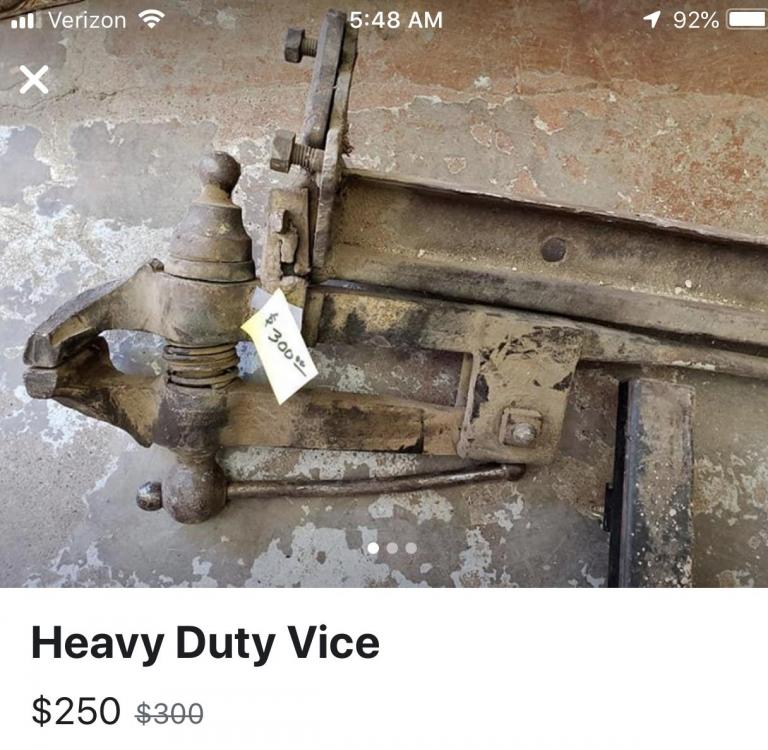

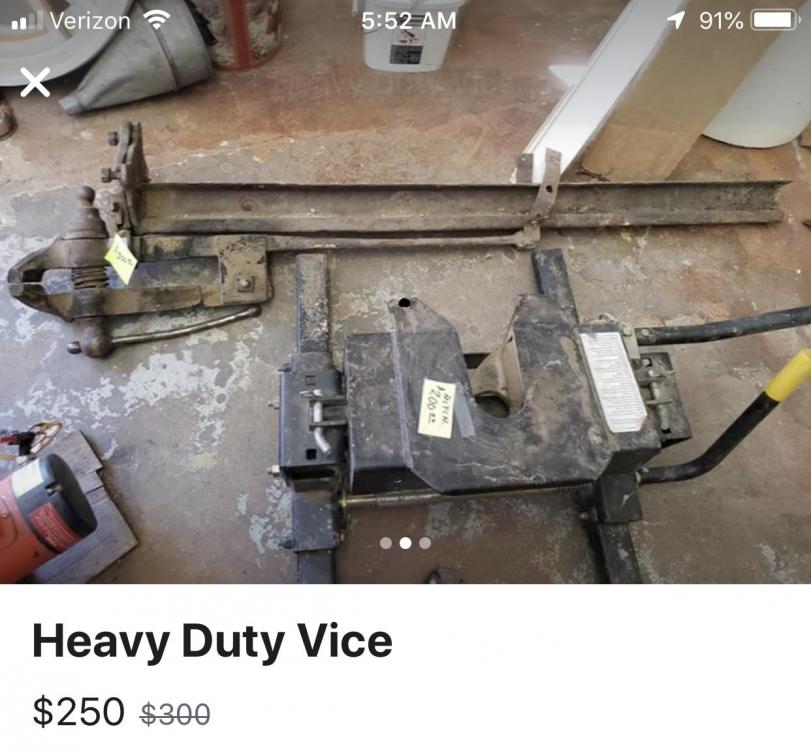

The title says it all. I saw a listing for a 4” post vice thats in decent shape but needs a spring. I’ve never looked into post vices so but the price is well below what I normally see. Assuming everything but needing a new spring is fine, is it a “buy” at $100?

-

Hmmm... I wonder how long it would take to cook a brat in my forge. It would certainly make it smell a little better.

-

I came here to ask a similar question. Does anybody have an opinion on wall thickness of the pipe?

-

Upon closer review, the “1 hp” motor is actually only pushing out 3/4 hp if you’re running on 110.

From the OBM website::

- The VFD is wired for 110V so the motor produces 3/4hp at 3600rpm which is ample for knife grinding but it can also be rewired for 220V if you wish for the motor to produce 1hp (original instructions for the VFD enclosed).

-

14 hours ago, Latticino said:

...use of a VFD to convert either 120 or 240 household sources to three phase for a 3 phase motor to drive a belt grinder. My understanding is that under those conditions you give up a bit of brake horsepower if you use the 120.

On both the OBM and Pheer websites they list the 2 hp motor as only getting 1.5 if you’re running on 110.

As an aside... Why do some folks refer to 120 and others 110? In the USA they are often used interchangeably in informal conversation but I live out west and it has always been 110 or 220 out here. Is it still 120 in some places?

-

6 hours ago, Latticino said:

I have a question about the jump from 1 hp to 1.5 hp. Both Pheer and OBM sell a 1 hp setup with a VFD and a 1.5 hp setup. I’m thinking of just getting an OBM but I want to know how big of a difference I’ll see if I just get the 1 hp with the KBAC-24.

-

I am in the US (Idaho). I’m specifically wondering if I’d have trouble running something like a Kalamazoo 2FS (2x48)

-

I have an idea and I’m wondering if it will work.

I have access to a variable speed bench grinder (5 amp Delta). Is there any reason I couldn’t slap a pulley for a v belt on that sucker and use it to run a Coote, Kalamazoo, or a Grizzly?

-

7 hours ago, Frosty said:

Rather than buy "Rigidizer" as such buy colloidal or fumed silica and mix up your own. Mikey has it laid out with sources in the Forges 101 thread it's pretty common stuff a fraction the price and has a long LONG shelf life. Premixed rigidizers have a pretty limited shelf life. Mike also likes to ad food coloring to the mix to show where and how much you've spritzed.

Frosty The Lucky.

You people are awesome.

-

I emailed the guy who sold it to me. It is not rigidized. I’ll have to buy some and get on that.

-

18 hours ago, Irondragon Forge & Clay said:

Looks like a very well constructed forge to me. What make is it?

BTW: What did you decide on the anvil you were looking at?

It was a DIY by a guy in Utah.

I didn’t buy the anvil. I’ve got a chunk of RR track for now.

16 hours ago, John in Oly, WA said:Suggestions? More pictures - showing the inside when it's not lit, and the burner flames when it is lit. Then we could see what you have and if it needs anything done.

From just looking at the one pic, I'd say get a couple of bricks to put on that front porch (maybe extend the sides of the porch or add angle iron to help hold the bricks) to slide side to side to cover that big opening. If that's ceramic blanket I'm seeing inside, make sure it's rigidized. Then I'd add another 1" of ceramic blanket, rigidize that, slather a 1/2" of kastolite 30 over that, then paint on some matrikote. But that's just guessing from the view of the one pic.

This is gonna’ sound dumb but, how can you tell if it’s rigidized? How “rigid” will it be?

I’ll post more photos later. I’ve been too busy keeping the criminals out of jail (day job) to have time to play.

-

-

1st post ever.

I’ve been lurking on the board for a while gathering info on burners, grinders, etc... This anvil popped up on a local buy/sell page and I’m thinking of picking it up.

All I know is the approximate weight (200 lbs) and the price $450.

What (if anything) can anybody tell me from the photos?

It won’t forge weld

in Knife Making

Posted

Thanks! Unfortunately, I’ve exceeded my available play time for this week (but I had a really good excuse) so I’ll have to see if I can get time to try again this weekend.

Maybe if my clients would stop committing crimes I would be better at this whole blacksmithing thing.